Honda Civic Service Manual: M/T Mainshaft Assembly Clearance Inspection (K24Z7)

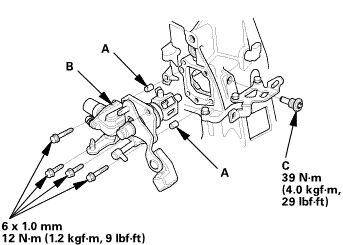

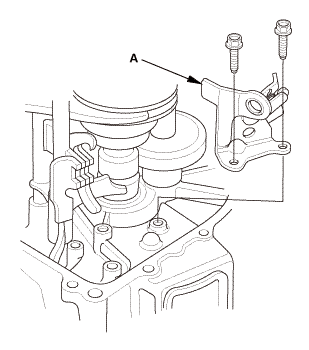

Removal

| 1. | M/T Change Lever Assembly |

|

|

|

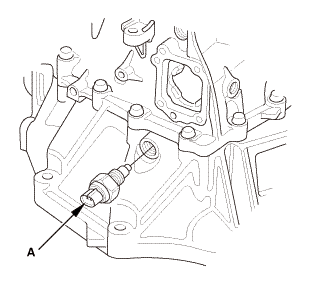

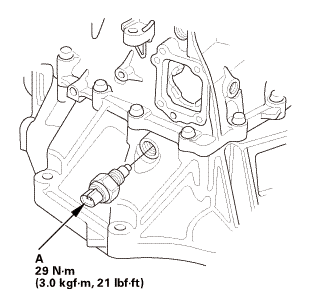

| 2. | Back-Up Light Switch |

|

|

|

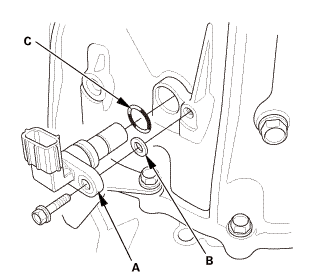

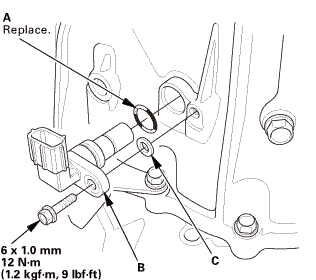

| 3. | Output Shaft (Countershaft) Speed Sensor |

|

|

|

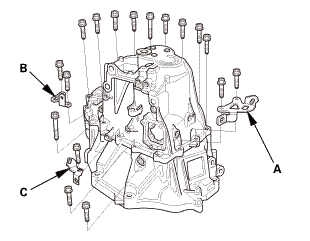

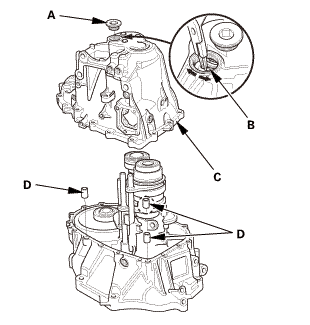

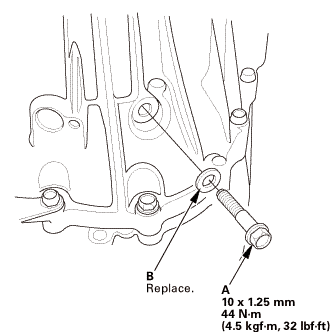

| 4. | Transmission Housing |

|

|

|

|

|

|

|

|

|

|

|

|

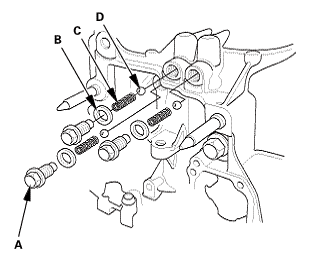

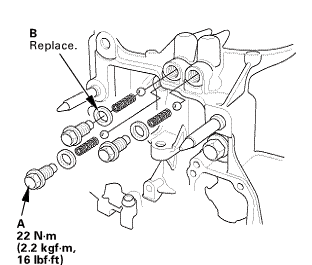

| 5. | Reverse Shift Fork |

|

|

|

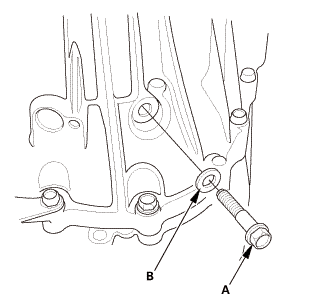

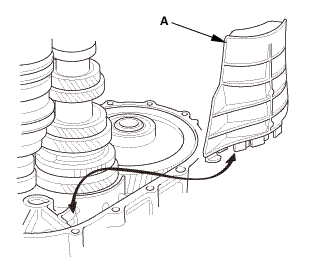

| 6. | Baffle Plate |

|

|

|

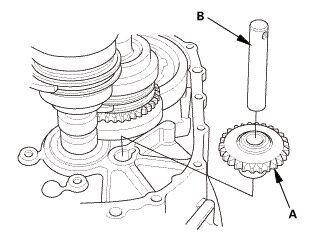

| 7. | Reverse Idler Gear |

|

|

|

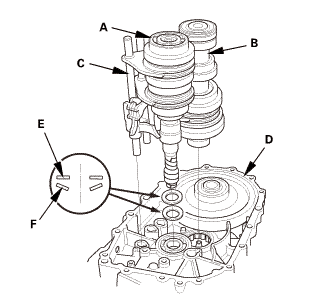

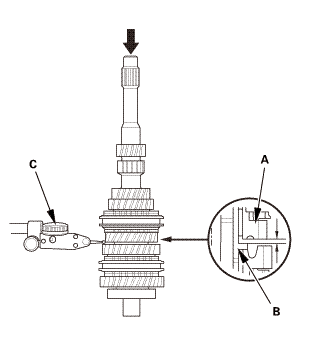

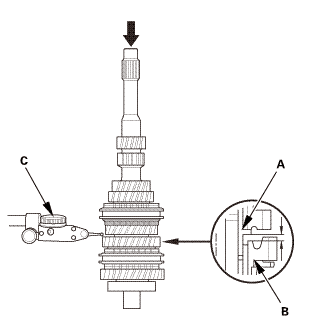

| 8. | M/T Mainshaft and Countershaft and Shift Fork Assembly |

|

|

|

|||||||||||||||

Inspection

Inspection

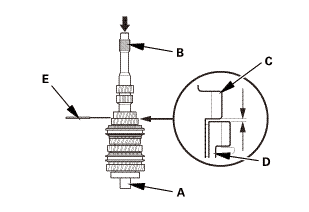

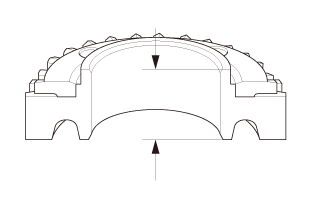

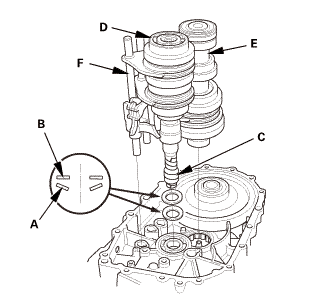

| 1. | Mainshaft Assembly Clearance Inspection |

|

|

|

||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

||||||||||||

|

|

|

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

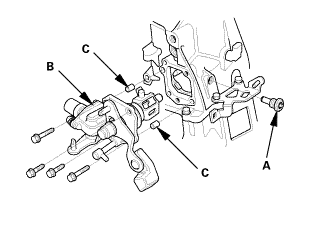

Installation

| 1. | M/T Mainshaft and Countershaft and Shift Fork Assembly |

|

|

|

||||||||||||||||||

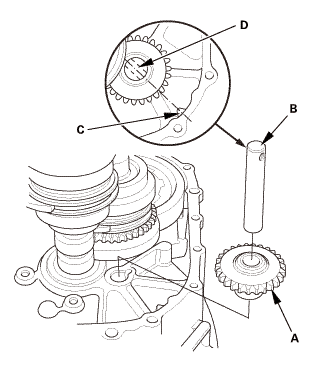

| 2. | Reverse Idler Gear |

|

|

|

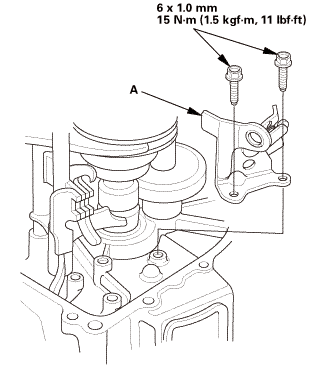

| 3. | Baffle Plate |

|

|

|

| 4. | Reverse Shift Fork |

|

|

|

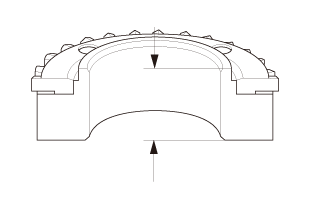

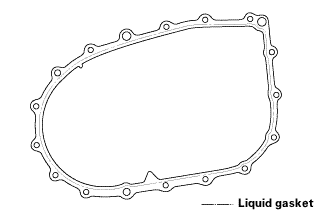

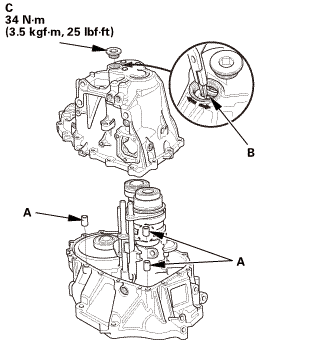

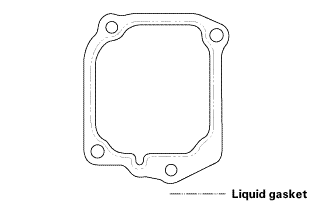

| 5. | Transmission Housing |

|

|

|

||||||||||||||||||||

|

|

|

|||||||||||||||

|

|

|

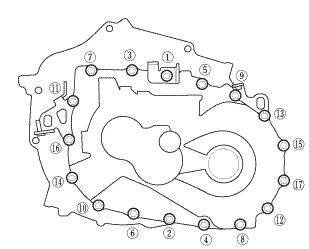

|||||||||||||||||||||||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

| 6. | Output Shaft (Countershaft) Speed Sensor |

|

|

|

| 7. | Back-Up Light Switch |

|

|

|

| 8. | M/T Change Lever Assembly |

|

|

|

||||||||||||||||||||

|

|

|

M/T Countershaft Disassembly, Reassembly, and Inspection (K24Z7)

M/T Countershaft Disassembly, Reassembly, and Inspection (K24Z7)

Disassembly

NOTE: Refer to the Exploded View as needed during this procedure.

1.

M/T Change Lever Assembly

...

M/T Mainshaft Assembly Clearance Inspection (R18Z1 M/T)

M/T Mainshaft Assembly Clearance Inspection (R18Z1 M/T)

Disassembly

1.

M/T Change Lever Assembly

1.

Remove the change lever assembly (A).

...

See also:

Honda Civic Owners Manual. In Case of Emergency

Automatic collision notification

If your vehicle's airbags deploy or if the unit

detects that the vehicle is severely impacted,

your vehicle automatically will attempt to

connect to the HondaLink operator. If

connected, information about your vehicle, its

location, and its condition can be ...

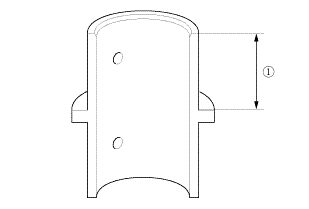

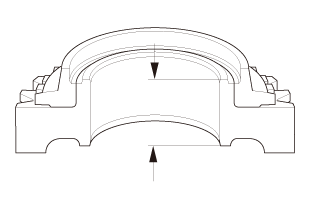

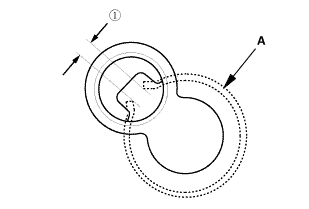

of the 4th/5th

gear distance collar as shown.

of the 4th/5th

gear distance collar as shown.

of the 4th/5th

gear distance collar as shown.

of the 4th/5th

gear distance collar as shown.

mmlbf!

mmlbf!

iukn

iukn