Honda Civic Service Manual: Synchro Ring and Gear Inspection (K24Z7)

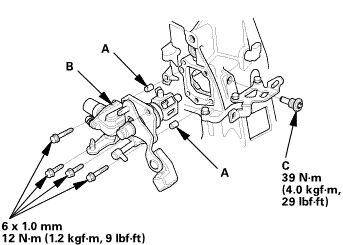

Removal

| 1. | M/T Change Lever Assembly |

|

|

|

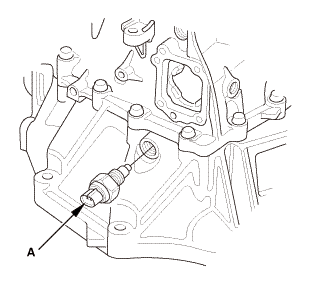

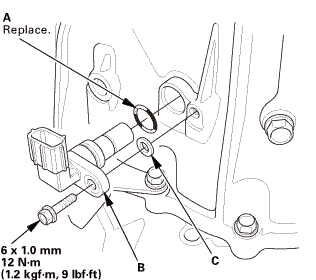

| 2. | Back-Up Light Switch |

|

|

|

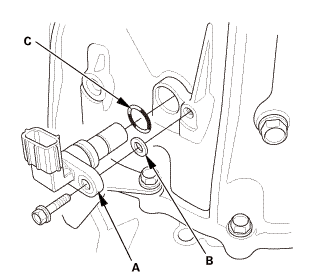

| 3. | Output Shaft (Countershaft) Speed Sensor |

|

|

|

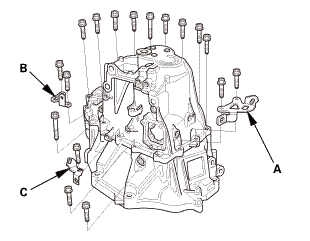

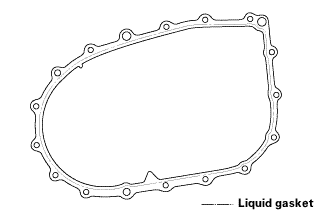

| 4. | Transmission Housing |

|

|

|

|

|

|

|

|

|

|

|

|

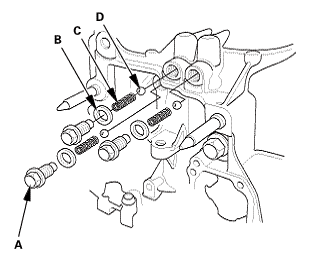

| 5. | Reverse Shift Fork |

|

|

|

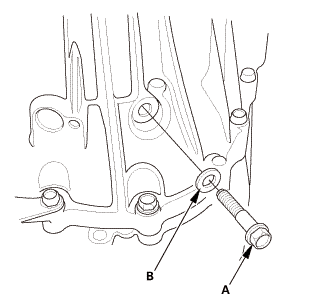

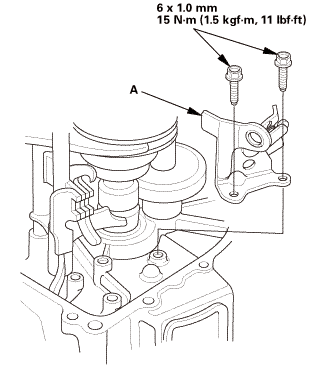

| 6. | Baffle Plate |

|

|

|

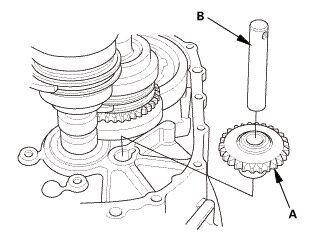

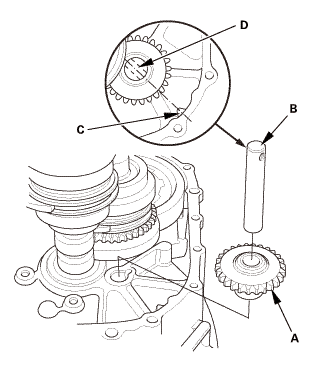

| 7. | Reverse Idler Gear |

|

|

|

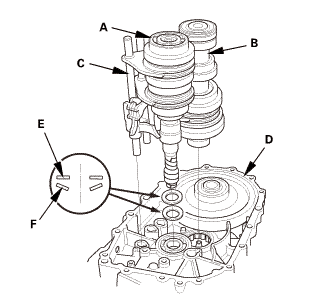

| 8. | M/T Mainshaft and Countershaft and Shift Fork Assembly |

|

|

|

|||||||||||||||

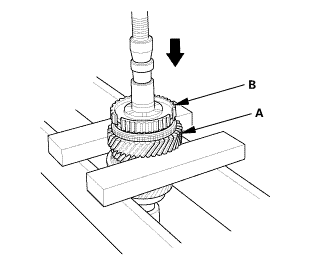

| 9. | M/T Mainshaft 5th and 6th Gear |

|

|

|

|

|

|

|||||||||

| 10. | M/T Mainshaft 3rd and 4th Gear |

|

|

|

|||||||||

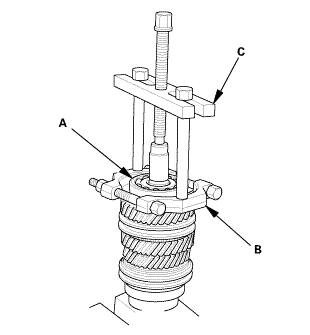

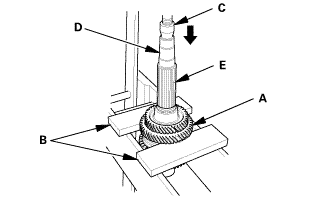

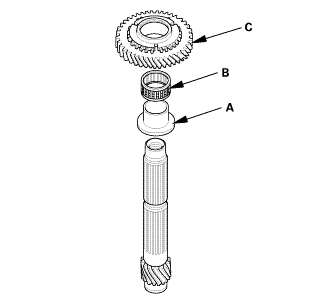

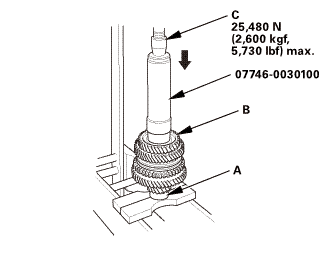

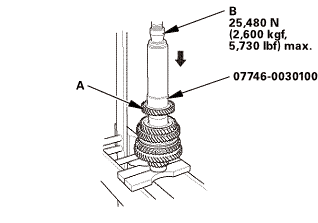

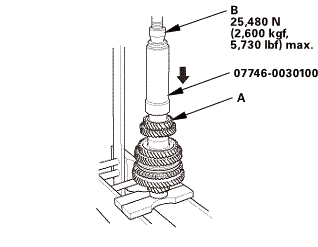

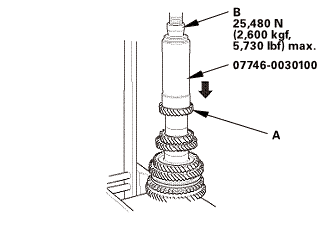

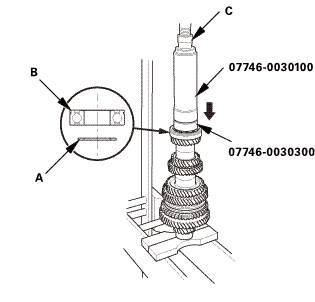

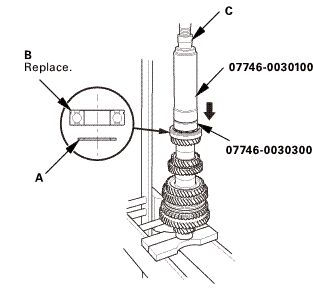

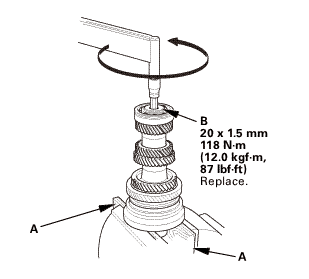

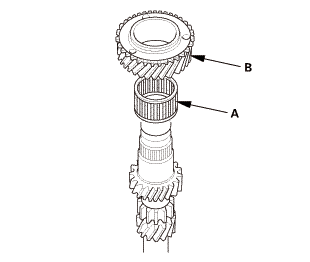

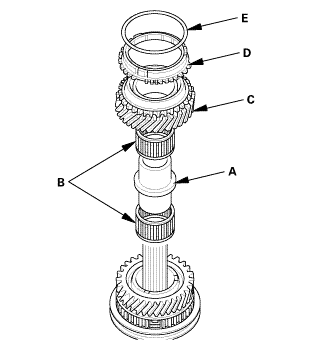

| 11. | M/T Countershaft |

|

|

|

|

|

|

|

|

|

|

|

|

Inspection

Inspection

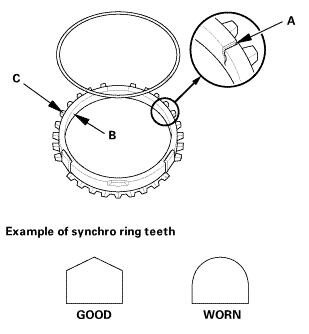

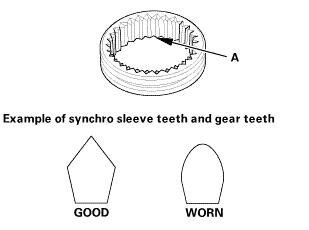

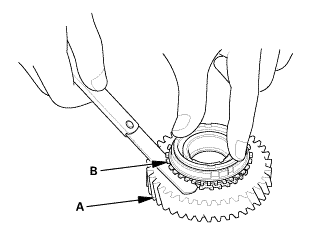

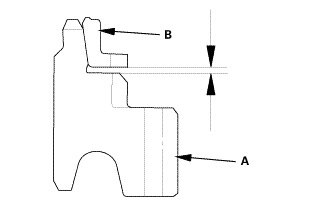

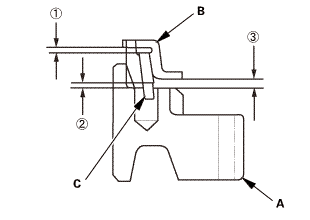

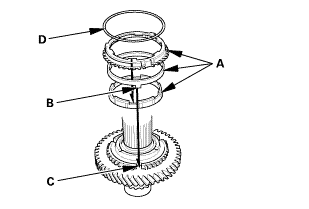

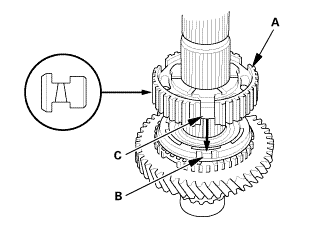

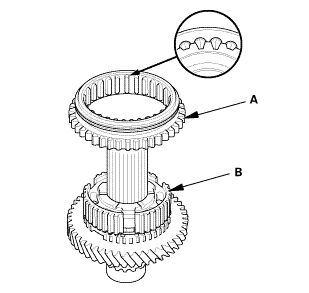

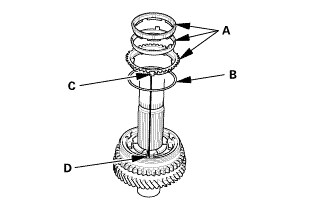

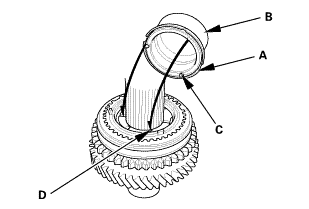

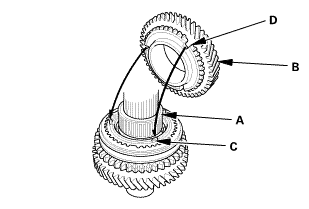

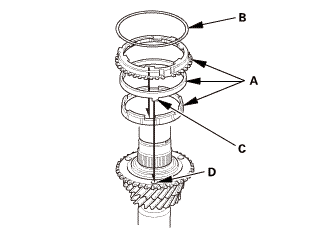

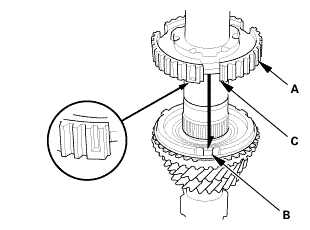

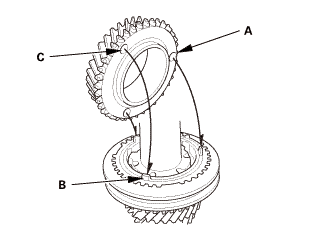

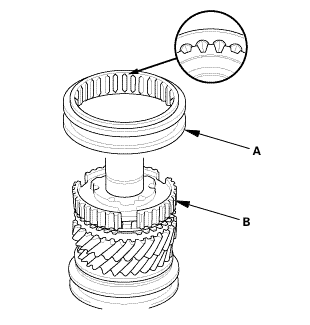

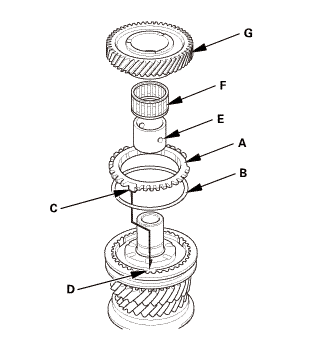

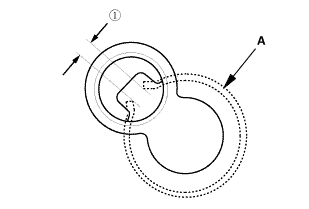

| 1. | Synchro Ring and Gear Inspection |

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

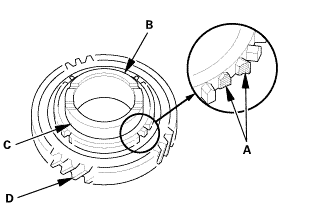

Synchro ring-to-gear

Double cone synchro and triple cone synchro-to-gear

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

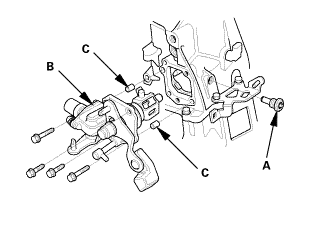

Installation

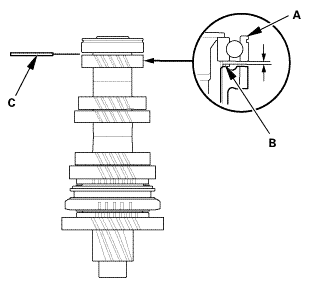

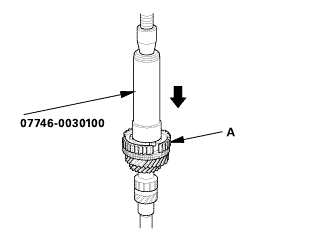

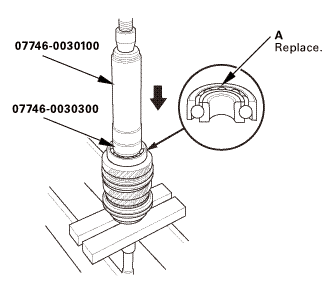

| 1. | M/T Countershaft |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

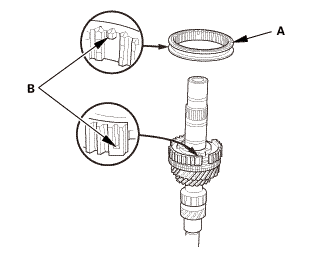

|

|

|

|

|

|

|

|

|

|

|

|||||||||

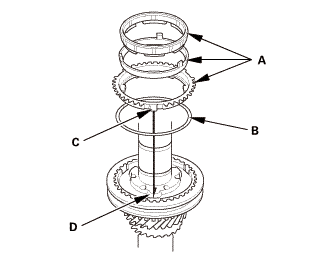

|

|

|

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

||||||

|

|

|

|||||||||||||||

|

|

|

|||||||||

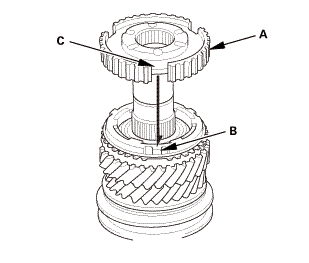

| 2. | M/T Mainshaft 3rd and 4th Gear |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

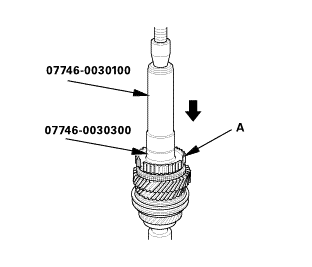

| 3. | M/T Mainshaft 5th and 6th Gear |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

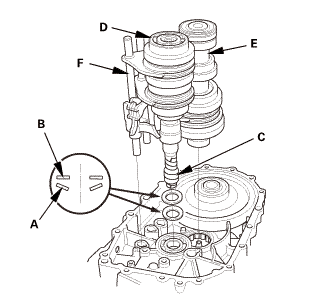

| 4. | M/T Mainshaft and Countershaft and Shift Fork Assembly |

|

|

|

||||||||||||||||||

| 5. | Reverse Idler Gear |

|

|

|

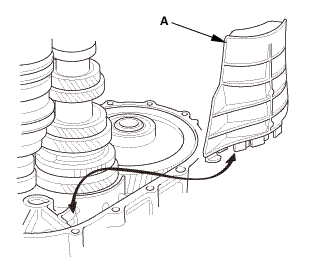

| 6. | Baffle Plate |

|

|

|

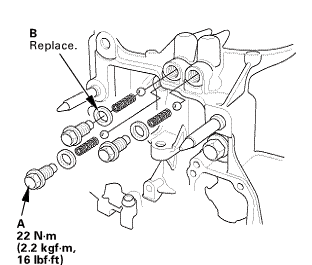

| 7. | Reverse Shift Fork |

|

|

|

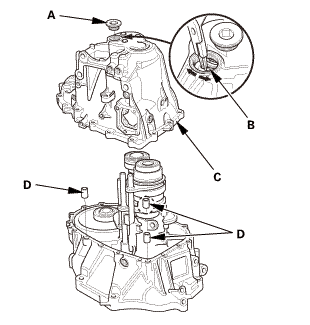

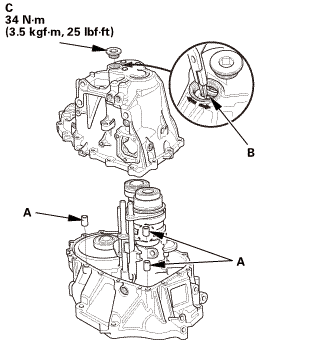

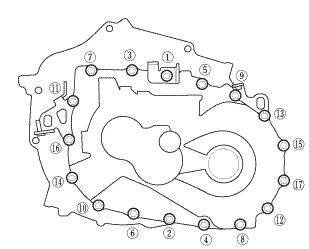

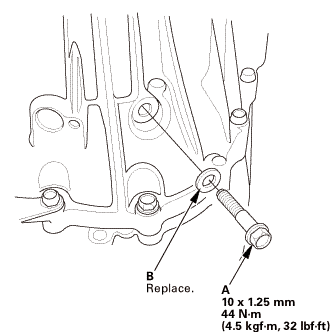

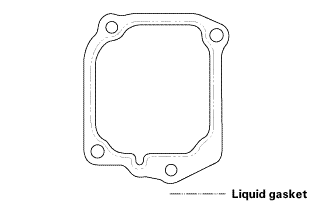

| 8. | Transmission Housing |

|

|

|

||||||||||||||||||||

|

|

|

|||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

| 9. | Output Shaft (Countershaft) Speed Sensor |

|

|

|

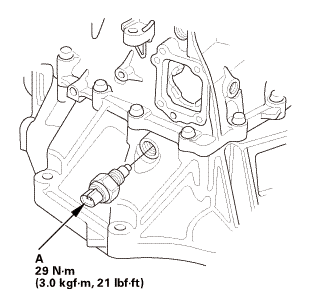

| 10. | Back-Up Light Switch |

|

|

|

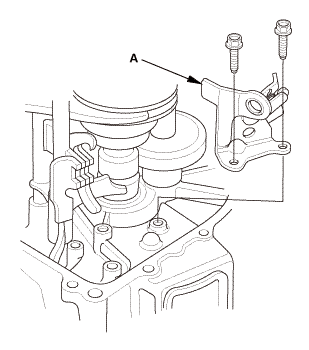

| 11. | M/T Change Lever Assembly |

|

|

|

||||||||||||||||||||

|

|

|

M/T Shift Fork Disassembly and Reassembly (R18Z1 M/T)

M/T Shift Fork Disassembly and Reassembly (R18Z1 M/T)

View

NOTE: Prior to reassembling, clean all parts in solvent, dry them, and

apply MTF to any contact surfaces.

1.

M/T Shift Fork Exploded View

...

Synchro Ring and Gear Inspection (R18Z1 M/T)

Synchro Ring and Gear Inspection (R18Z1 M/T)

Removal

1.

M/T Change Lever Assembly

1.

Remove the change lever assembly (A).

...

See also:

Honda Civic Owners Manual. When the System can be Used

The system can be used when the following conditions are met.

The lane in which you are driving has detectable lane markers on

both sides, and

your vehicle is in the center of the lane.

The vehicle speed is between 45 and 90 mph (72 and 145 km/h).

You are driving on a ...

sleeveandworm

sleeveandworm

:

: :

: :

:

sun

sun s,m

s,m (2,snn

(2,snn zs,4ioums.uuau1uu

zs,4ioums.uuau1uu nms.nn:mnn

nms.nn:mnn

nms.nu:n1nn

nms.nu:n1nn mm(noumn

mm(noumn

mmlbf!

mmlbf!

iukn

iukn