Honda Civic Service Manual: Right M/T Differential Oil Seal Replacement (R18Z1 M/T)

2191F5 RIGHT

| 1. | Vehicle Lift |

|

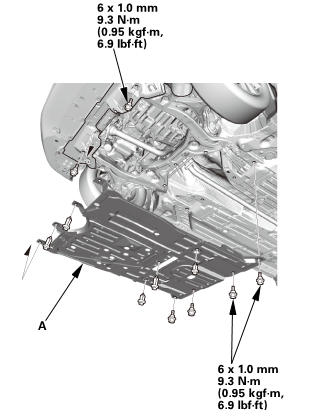

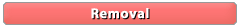

| 2. | Engine Undercover |

|

|

|

| 3. | MTF Replacement |

|

|

|

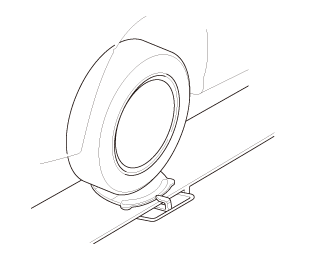

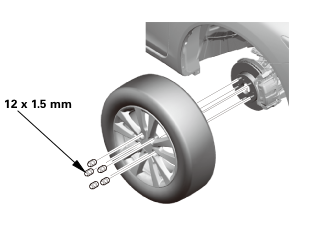

| 4. | Tire and Wheel-Removal, Front Right |

|

|

|

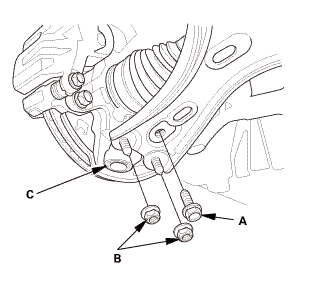

| 5. | Right Lower Ball Joint Lower Arm Side Disconnection |

|

|

|

| 6. | Right Front Driveshaft Inboard Side - Disconnection (With Intermediate Shaft) |

|

|

|

||||||

|

|

|

| 7. | Floor Jack Support (Except K24Z7 Engine) |

|

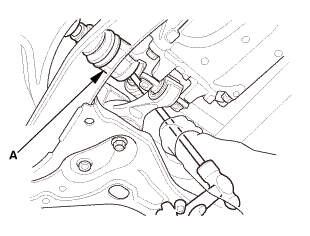

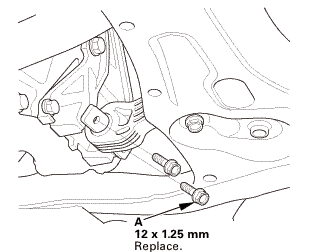

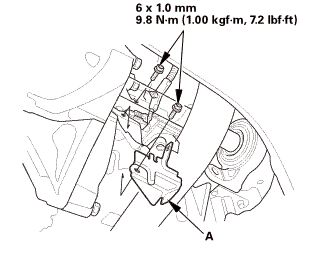

| 8. | Lower Torque Rod - Disconnection |

|

|

|

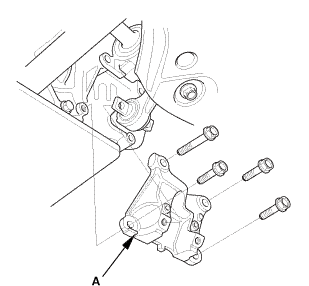

| 9. | Lower Torque Rod Bracket (Except K24Z7 Engine) |

|

|

|

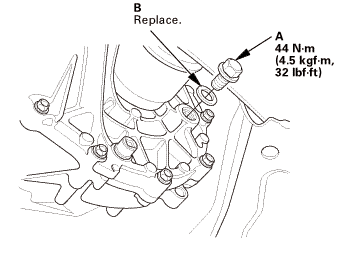

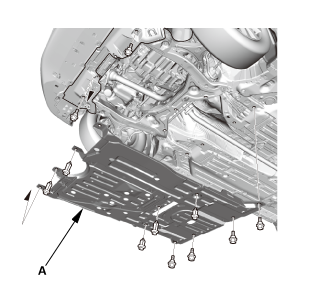

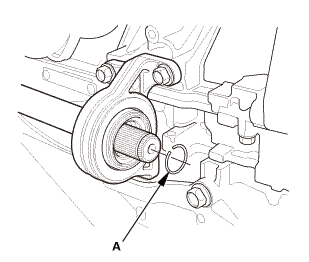

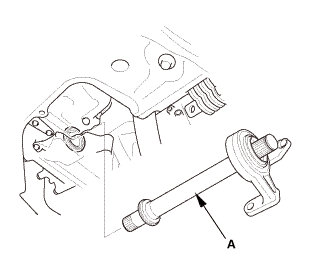

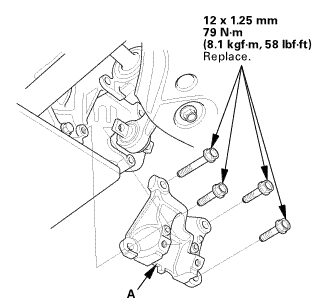

| 10. | Intermediate Shaft Assembly |

|

|

|

|

|

|

|

|

|

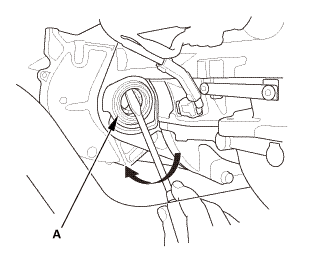

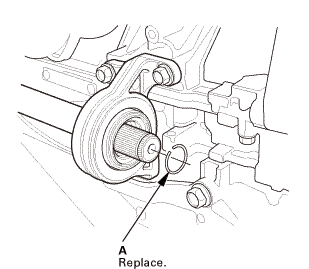

| 11. | M/T Differential Oil Seal, Right |

|

|

|

||||||

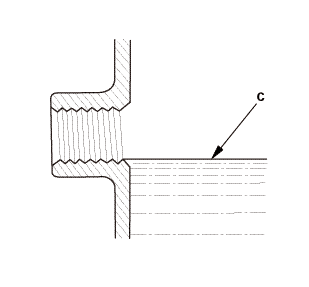

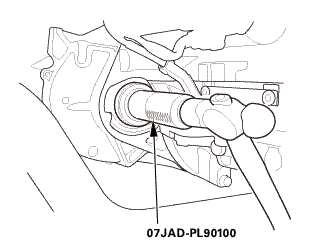

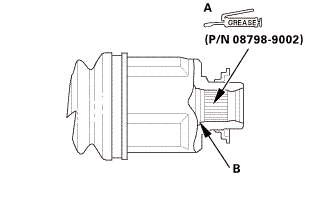

| 1. | M/T Differential Oil Seal, Right |

|

|

|

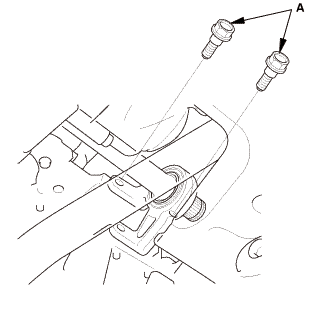

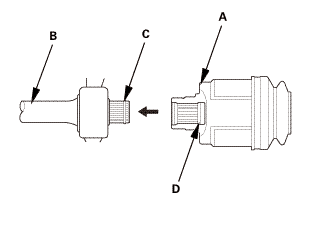

| 2. | Intermediate Shaft Assembly |

|

|

|

||||||

|

|

|

|

|

|

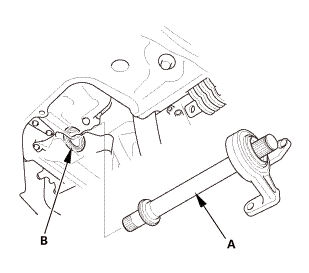

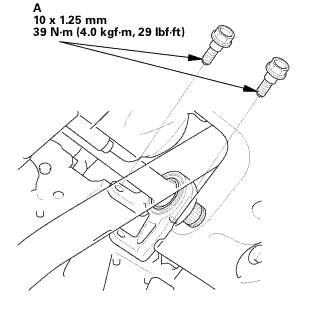

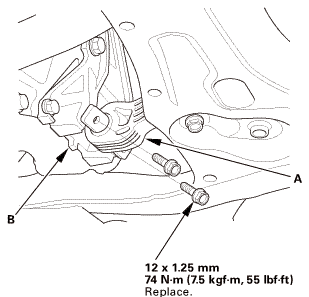

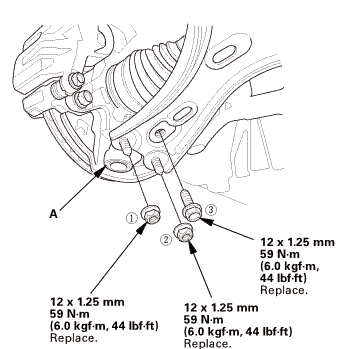

| 3. | Lower Torque Rod Bracket (Except K24Z7 Engine) |

|

|

|

| 4. | Lower Torque Rod - Reconnection |

|

|

|

| 5. | Floor Jack Support (Except K24Z7 Engine) |

|

| 6. | Right Front Driveshaft Inboard Side - Reconnection (With Intermediate Shaft) |

|

|

|

|

|

|

|

|

|

| 7. | Right Lower Ball Joint Lower Arm Side Reconnection |

|

|

|

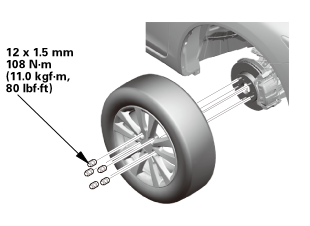

| 8. | Tire and Wheel-Installation, Front Right |

|

|

|

||||||

| 9. | Driveshaft After Install Check |

|

| 10. | MTF Replacement |

|

|

|

||||||||||||||||||||||||||

| 11. | Engine Undercover |

|

|

|

| 12. | Pre-Alignment Checks |

|

| 13. | Caster - Inspection |

|

|||||||||||||||||||||||||||||||||||||||||||||||

| 14. | Camber - Inspection |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15. | Front Toe - Inspection |

|

|||||||||||||||||||||||||

| 16. | Turning Angle - Inspection |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17. | Test Drive |

|

| 18. | Maintenance Minder Reset |

|

Right A/T Differential Oil Seal Replacement (A/T)

Right A/T Differential Oil Seal Replacement (A/T)

2191M0 RIGHT

1.

Vehicle Lift

1.

Raise the vehicle on a lift, and make sure it is securely supported.

...

M/T Differential Carrier and Final Driven Gear Removal and Installation (K24Z7)

M/T Differential Carrier and Final Driven Gear Removal and Installation (K24Z7)

2311F1

Removal

1.

M/T Change Lever Assembly

1.

Remove the interlock bolt (A).

...

See also:

Honda Civic Owners Manual. With Little Chance of a Collision

The CMBSTM may activate even when you are aware of a vehicle ahead of you, or

when there is no vehicle ahead. Some examples of this are:

When Passing

Your vehicle approaches another vehicle ahead of you and you change lanes to

pass.

At an intersection

Your vehicle approaches or pa ...

12x1mm

12x1mm

mmu....

mmu.... mms.

mms. mmmn

mmmn

(p/n

(p/n ei

ei replace.

replace. mminmuan

mminmuan