Honda Civic Service Manual: M/T Mainshaft Thrust Clearance Adjustment (K24Z7)

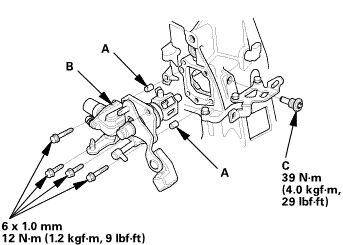

Removal

| 1. | M/T Change Lever Assembly |

|

|

|

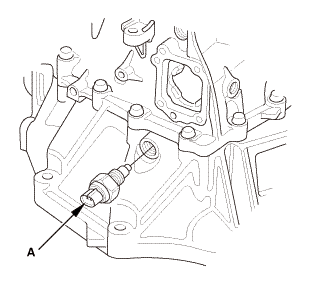

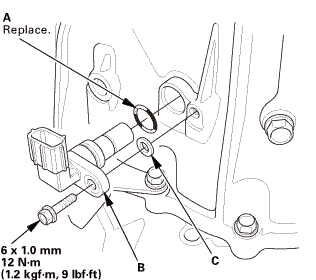

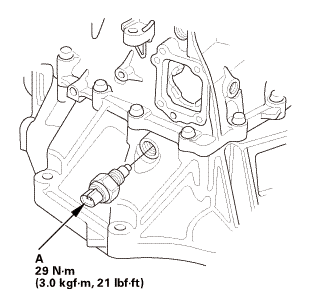

| 2. | Back-Up Light Switch |

|

|

|

| 3. | Output Shaft (Countershaft) Speed Sensor |

|

|

|

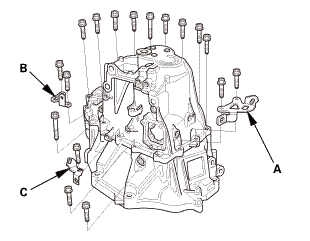

| 4. | Transmission Housing |

|

|

|

|

|

|

|

|

|

|

|

|

| 5. | Reverse Shift Fork |

|

|

|

| 6. | Baffle Plate |

|

|

|

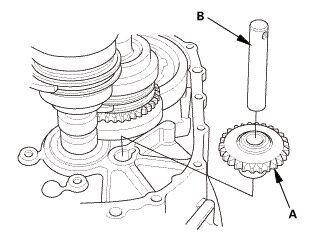

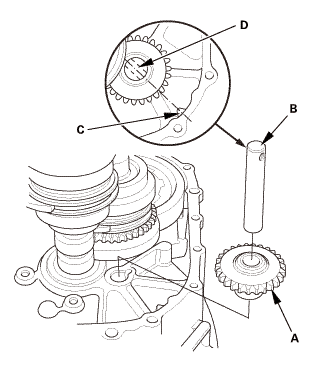

| 7. | Reverse Idler Gear |

|

|

|

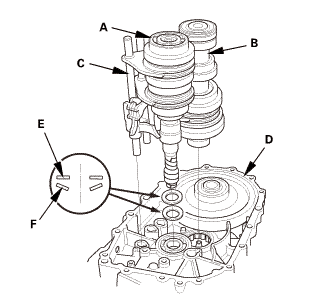

| 8. | M/T Mainshaft and Countershaft and Shift Fork Assembly |

|

|

|

|||||||||||||||

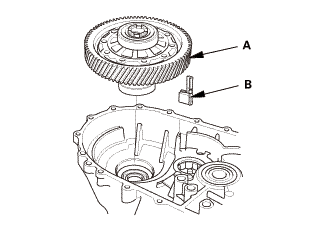

| 9. | Differential Assembly |

|

|

|

Adjustment

Adjustment

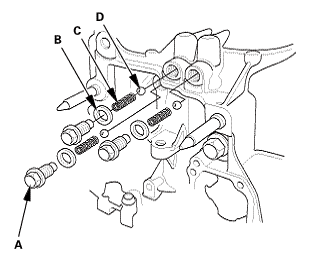

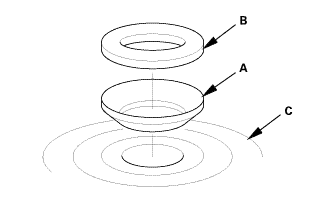

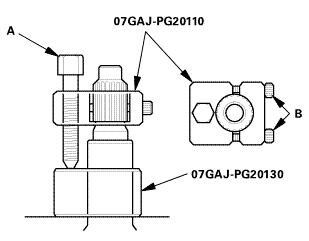

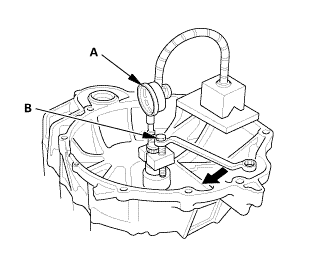

| 1. | M/T Mainshaft Thrust Clearance Adjustment |

|

|

|

|||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

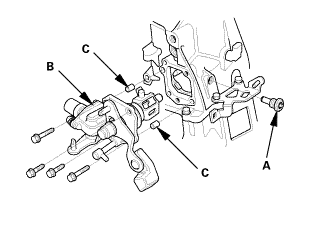

Installation

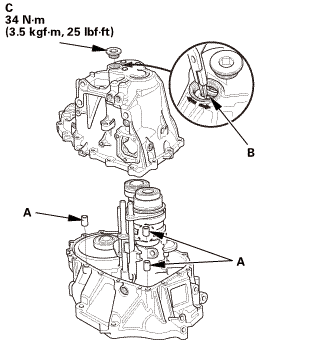

| 1. | Differential Assembly |

|

|

|

|||||||||

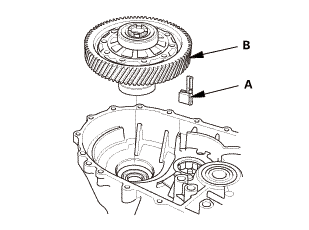

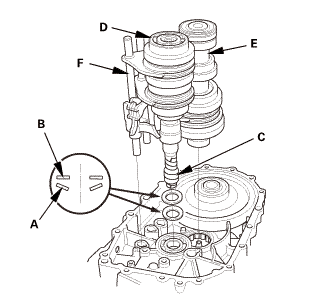

| 2. | M/T Mainshaft and Countershaft and Shift Fork Assembly |

|

|

|

||||||||||||||||||

| 3. | Reverse Idler Gear |

|

|

|

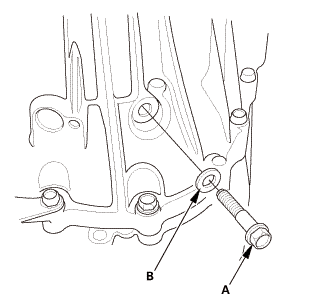

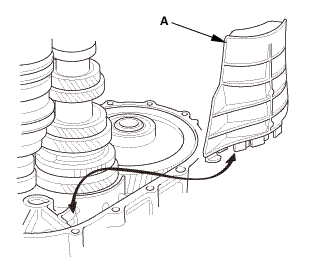

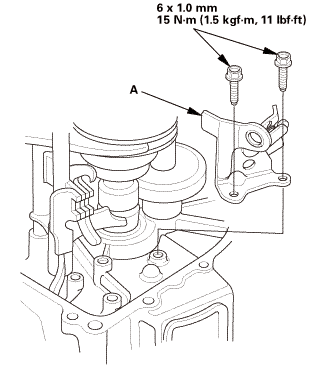

| 4. | Baffle Plate |

|

|

|

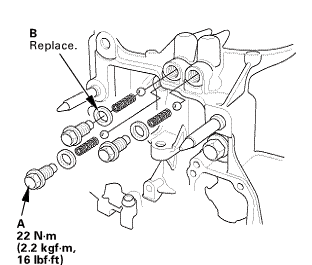

| 5. | Reverse Shift Fork |

|

|

|

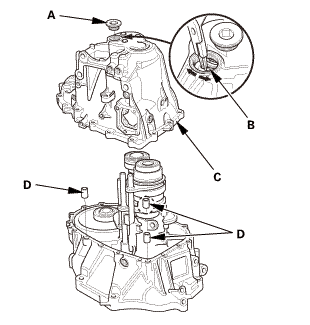

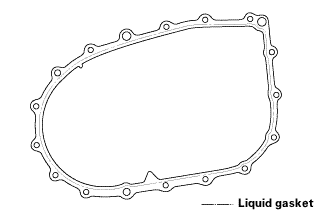

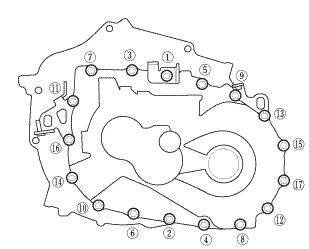

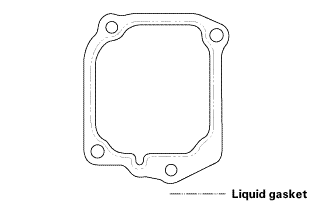

| 6. | Transmission Housing |

|

|

|

||||||||||||||||||||

|

|

|

|||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

| 7. | Output Shaft (Countershaft) Speed Sensor |

|

|

|

| 8. | Back-Up Light Switch |

|

|

|

| 9. | M/T Change Lever Assembly |

|

|

|

||||||||||||||||||||

|

|

|

M/T Mainshaft Disassembly, Reassembly, and Inspection (R18Z1 M/T)

M/T Mainshaft Disassembly, Reassembly, and Inspection (R18Z1 M/T)

Disassembly

NOTE: Refer to the Exploded View as needed during this procedure.

1.

M/T Change Lever Assembly

...

M/T Reverse Shift Fork Clearance Inspection (K24Z7)

M/T Reverse Shift Fork Clearance Inspection (K24Z7)

Removal

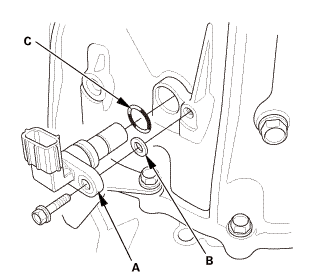

1.

M/T Change Lever Assembly

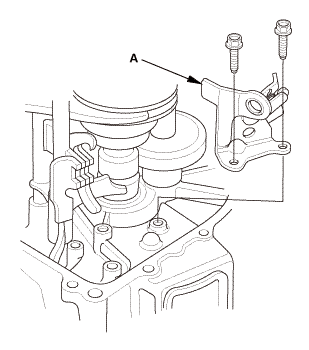

1.

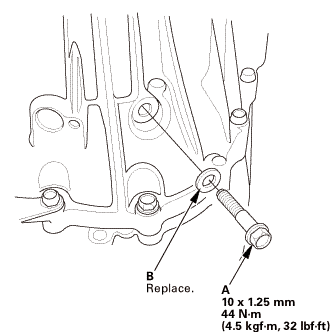

Remove the interlock bolt (A).

...

See also:

Honda Civic Service Manual. Rear Window Removal and Installation (4-door except Natural Gas models)

832120

Removal

1.

Rear Seat Cushion

1.

Remove the bolt (A) securing the rear seat cushion (B).

...

mmlbf!

mmlbf!

as installed:

3.3-6.0 mm (0.130-0.236 in)

as installed:

3.3-6.0 mm (0.130-0.236 in)

iukn

iukn