Honda Civic Service Manual: Engine Oil Pump Removal and Installation (Except K24Z7)

111150

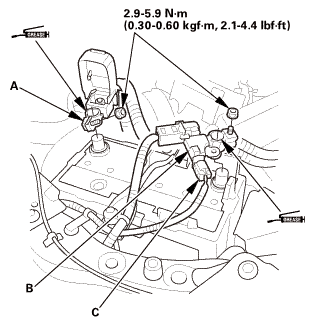

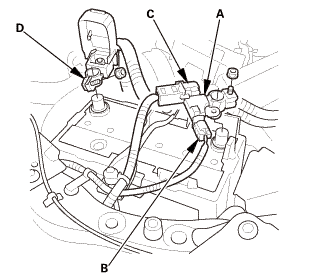

| 1. | Battery Terminal - Disconnection |

|

|

|

|||||||||||||||||||||||||||

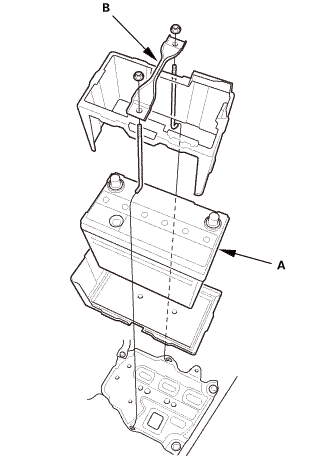

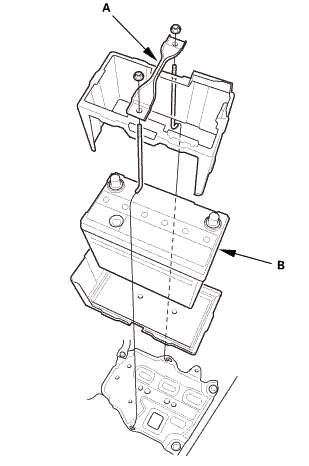

| 2. | Battery |

|

|

|

| 3. | Vehicle Lift |

|

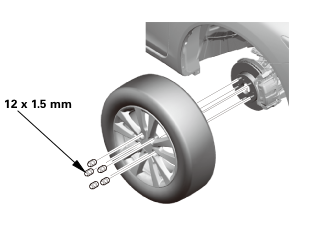

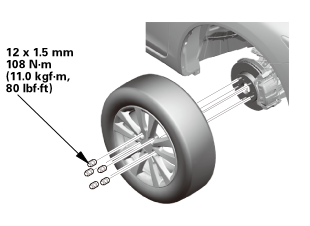

| 4. | Tire and Wheel-Removal, Front Right |

|

|

|

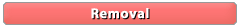

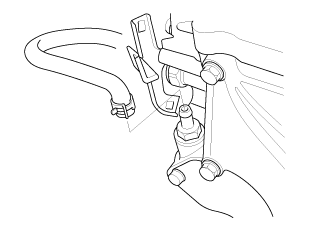

| 5. | Splash Shield |

|

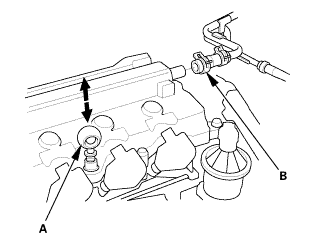

1. |

Remove the splash shield (A). |

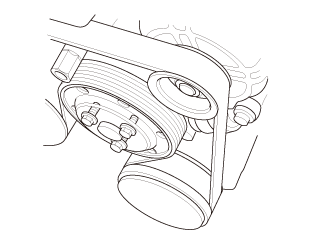

| 6. | Water Pump Pulley Mounting Bolt - Loosen |

|

|

|

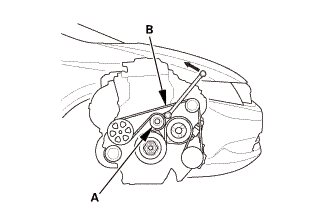

| 7. | Drive Belt |

|

|

|

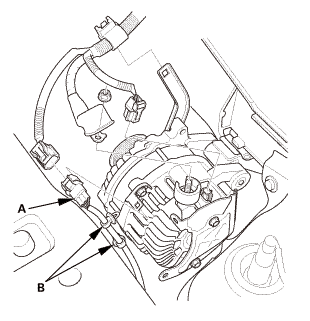

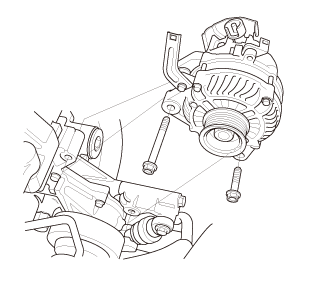

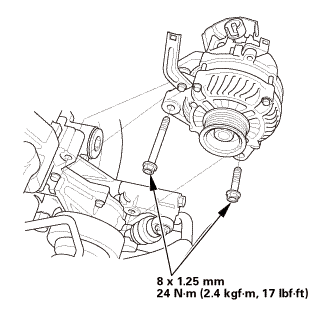

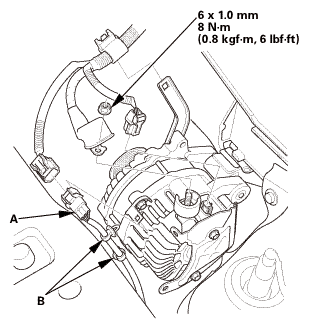

| 8. | Alternator |

|

|

|

|

|

|

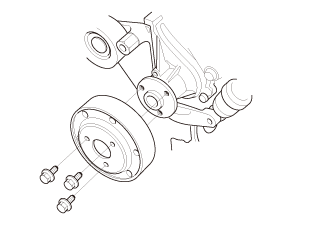

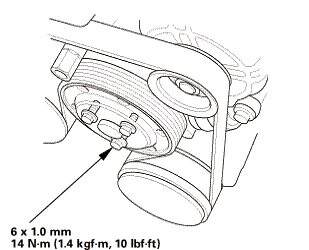

| 9. | Water Pump Pulley |

|

|

|

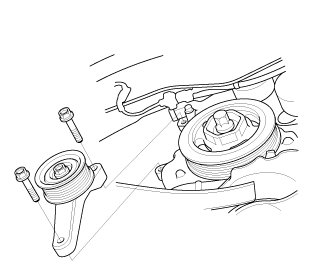

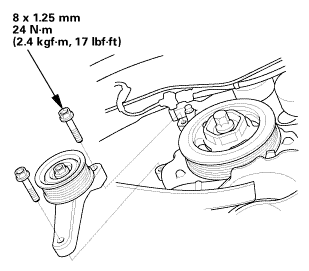

| 10. | Auto Tensioner Assembly |

|

|

|

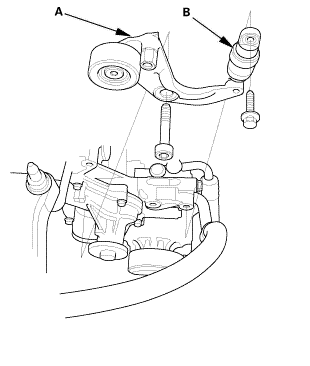

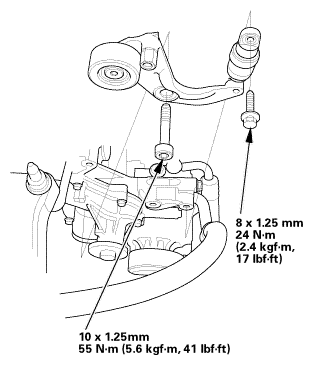

| 11. | Idler Pulley Base Assembly |

|

|

|

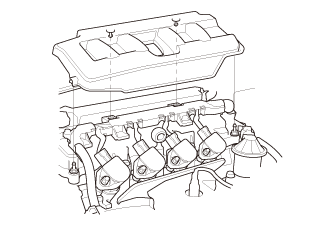

| 12. | Engine Cover |

|

|

|

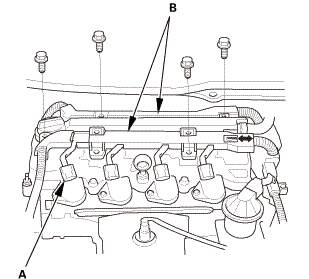

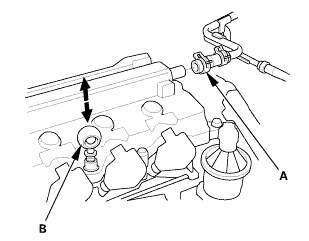

| 13. | Cylinder Head Cover Peripheral Assembly |

|

|

|

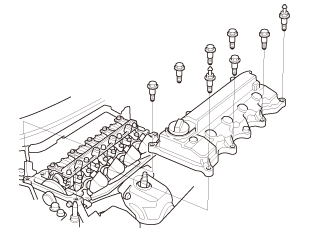

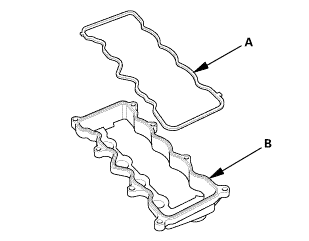

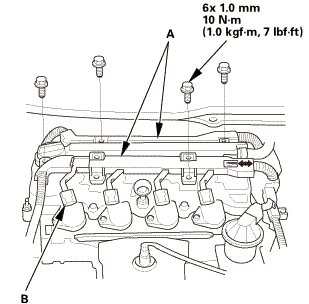

| 14. | Cylinder Head Cover and/or Packing |

|

|

|

|

|

|

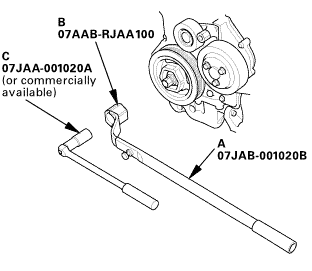

| 15. | Crankshaft Pulley |

|

|

|

| 16. | Engine Jack Support (State Of A Low Vehicle) |

|

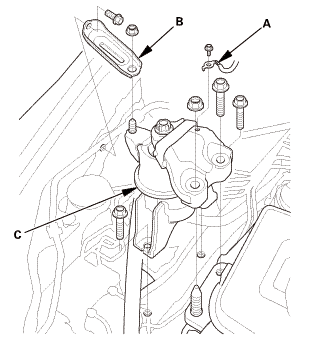

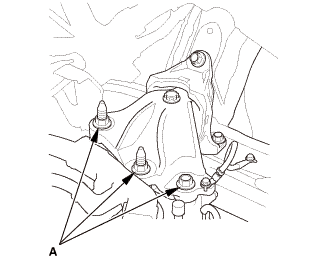

| 17. | Mounting Bracket, Engine Side |

|

|

|

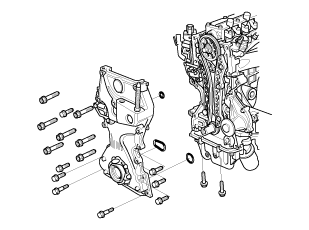

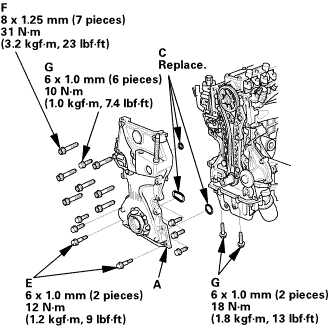

| 18. | Engine Oil Pump Assembly |

|

|

|

|

|

|

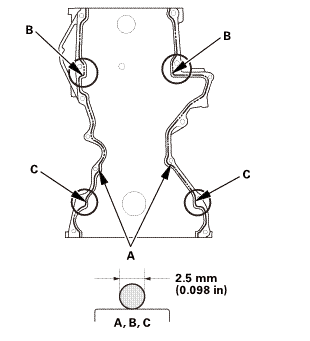

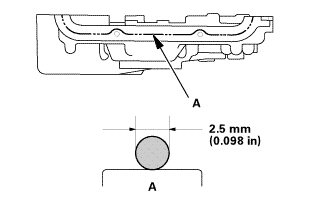

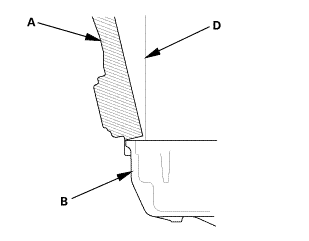

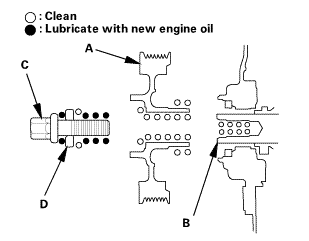

| 1. | Engine Oil Pump Assembly |

|

|

|

||||||||||||||||||||||||||

|

|

|

||||||||||||||

|

|

|

||||||||||||||||||||||||||||||

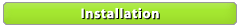

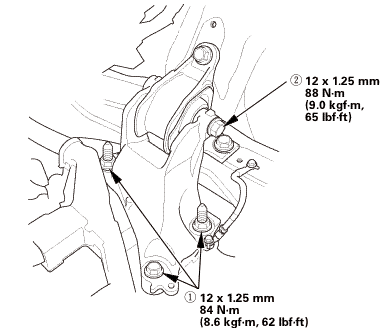

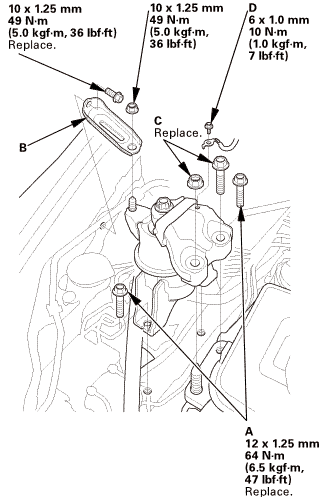

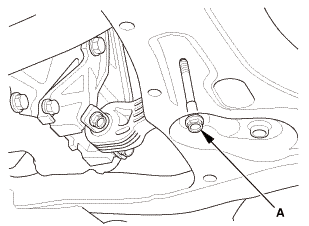

| 2. | Mounting Bracket, Engine Side |

|

|

|

| 3. | Engine Jack Support (State Of A Low Vehicle) |

|

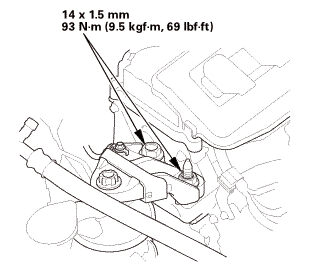

| 4. | Transmission Mount Bracket Mounting Bolt - Loosen |

|

M/T

A/T

|

|

| 5. | Lower Torque Rod - Loosen |

|

|

|

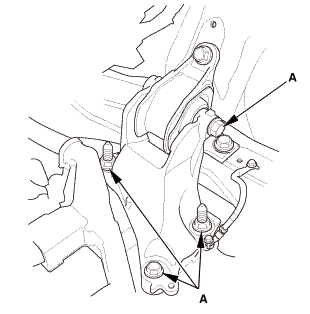

| 6. | Side Engine Mount - Tighten |

|

|

|

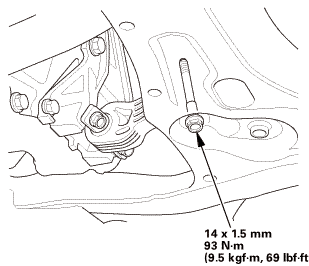

| 7. | Transmission Mount Bracket Mounting Bolt - Tighten |

|

1. |

Tighten the transmission mount bracket mounting bolt and nuts. |

M/T

i2mm

i2mm

A/T

nz

nz

| 8. | Lower Torque Rod Mounting Bolt - Tighten |

|

|

|

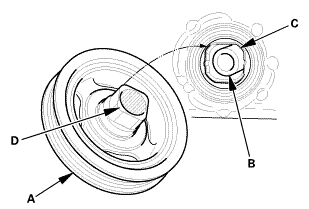

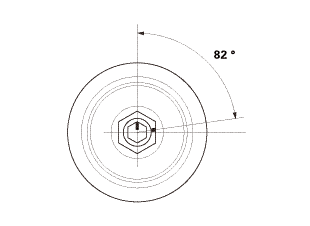

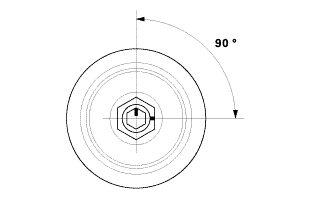

| 9. | Crankshaft Pulley |

|

|

|

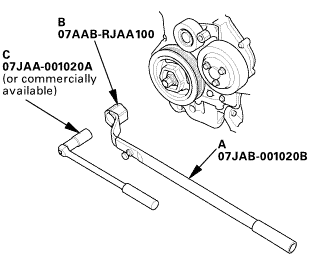

|

|

|

|

|

|

|||||||||||||

|

|

|

||||||||||

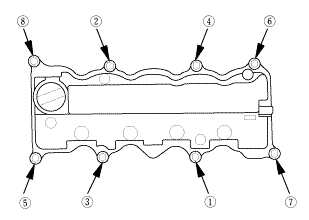

| 10. | Cylinder Head Cover and/or Packing |

|

|

|

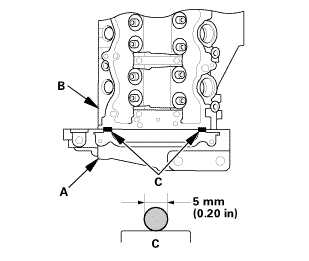

|||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

| 11. | Cylinder Head Cover Peripheral Assembly |

|

|

|

| 12. | Engine Cover |

|

|

|

| 13. | Idler Pulley Base Assembly |

|

|

|

| 14. | Auto Tensioner Assembly |

|

|

|

| 15. | Water Pump Pulley |

|

|

|

| 16. | Alternator |

|

|

|

|

|

|

| 17. | Drive Belt |

|

|

|

| 18. | Water Pump Pulley Mounting Bolt - Tighten |

|

|

|

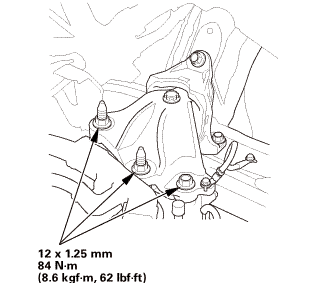

| 19. | Splash Shield |

|

1. |

Install the splash shield (A). |

| 20. | Tire and Wheel-Installation, Front Right |

|

|

|

||||||

| 21. | Battery |

|

|

|

||||||

| 22. | Battery Terminal - Reconnection |

|

|

|

|||||||||||||||||||

Engine Oil Pump Overhaul (K24Z7)

Engine Oil Pump Overhaul (K24Z7)

View

1.

Oil Pump Exploded View

Exploded View

mm27allon.pumpnowel......-m(1.2holder/bysoninbore

Disassembly

NOTE: Refer to the Exploded View ...

Engine Block Drain Bolt/Sealing Bolt Removal and Installation (Except K24Z7)

Engine Block Drain Bolt/Sealing Bolt Removal and Installation (Except K24Z7)

Replacement

1.

Sealing Bolt

NOTE: When installing the drain bolt and/or sealing bolt, always use

new washers.

l.5mm75mm35mmmmkglm,i25mm75

...

See also:

Honda Civic Owners Manual. Protecting Infants

An infant must be properly restrained in a rear-facing, reclining child seat

until the

infant reaches the seat manufacturer’s weight or height limit for the seat, and

the

infant is at least one year old. Many experts recommend use of a rear-facing

seat for

a child up to two years old if t ...

12x1mm

12x1mm

[av

[av

25mm(7(32k1n1omm12

25mm(7(32k1n1omm12

125mmnminm.:125mm

125mmnminm.:125mm

nxl.mm

nxl.mm

o7jaanmo2oa

o7jaanmo2oa

mmidnmm,

mmidnmm,

inl.25mmssn-m

inl.25mmssn-m mmn-m(2

mmn-m(2 i.nmm(n.i

i.nmm(n.i

mminmuan

mminmuan