|

|

If an accidental system discharge occurs, ventilate the work

area before resuming service.

|

|

|

|

Additional health and safety information may be obtained from

the refrigerant and lubricant manufacturers.

|

|

|

|

Check the system for leaks using an R-134a refrigerant leak detector

with an accuracy of 14 g (0.5 oz) per year or better.

|

|

|

|

Do not install an A/C compressor into a system unless you are

completely sure that the system is free of contamination. Installing

the A/C compressor into a contaminated system can result in premature

A/C compressor failure.

|

|

|

|

Inspect the A/C lines for any signs of contamination.

|

|

|

|

If you're installing a new A/C compressor, you must calculate

the amount of refrigerant oil to be removed from it. A new A/C compressor

comes with a full charge of oil.

|

|

|

|

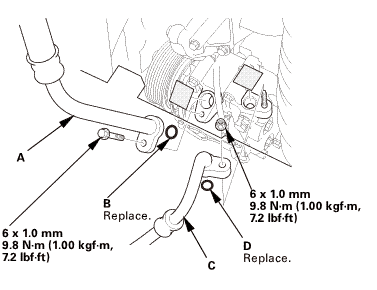

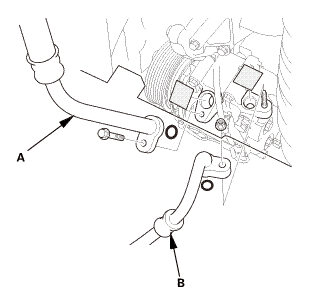

Replace the O-rings with new ones at each fitting, and apply

a thin coat of refrigerant oil before installing them. Be sure to

use the correct O-rings for HFC-134a (R-134a) to avoid leakage.

|

|

|

|

Use only PAG refrigerant oil (SP-10) for HFC-134a A/C systems.

|

|

|

|

To avoid contamination, do not return the oil to the container

once dispensed, and never mix it with other refrigerant oils.

|

|

|

|

Immediately after using the oil, reinstall the cap on the container,

and seal it to avoid moisture absorption.

|

|

|

|

Do not spill the refrigerant oil on the vehicle; it may damage

the paint; if the refrigerant oil contacts the paint, wash it off

immediately.

|

|

|

|

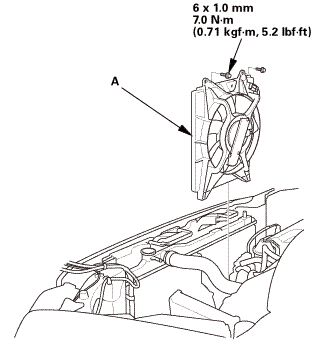

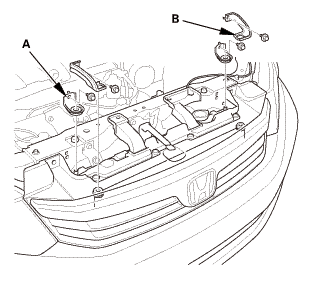

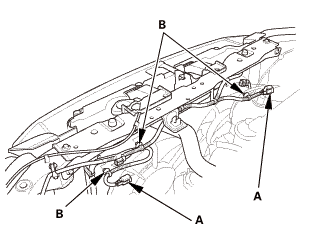

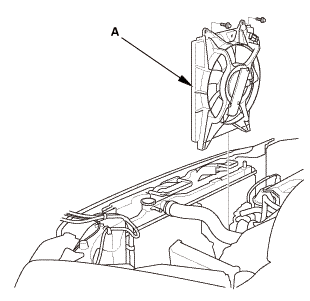

Be careful not to damage the radiator fins when installing the

A/C compressor, the alternator or the A/C condenser fan shroud.

|

|

|

|

Position the vehicle in a wind-free work area. This will aid

in detecting small leaks.

|

|

|

|

When using the leak detector for the first time, allow it to

warm up for 2 minutes with the probe in a clean atmosphere. This

lets the temperature sensor in the detector stabilize.

|

|

|

|

The calibration check should be done in the ‘‘Search 2’’

mode. Once that is done, the other check modes do not need calibrating.

|

|

|

|

When leak checking through the HVAC module drain hose, avoid

drawing water into the probe. Water can damage the internal pump

and sensor.

|

|

|

|

Avoid creasing the flexible probe extension. Creases can restrict

air flow and give false readings.

|

|

|

|

Because the detector recalibrates itself for ambient gases, it

may be necessary to move the detector away from the leak to clear

the sensor. Once the sensor has cleared, recheck the suspected leak.

|

|

|

|

When removing the clear probe tip, be careful not to lose the

flow ball.

|

|

|

|

R-134a is heavier than air; always check below and to the sides

of all potential leak sources.

|

|

|

|

Halogen leak detectors are sensitive to chemicals: windshield

washing solutions, solvents/cleaners, and some vehicle adhesives.

Keep these chemicals out of the area when doing leak detection.

|

|

|

|

Use only Tracer-Stick single dose fluorescent dye capsules from

Tracerline®. Other dyes contain solvents that may contaminate the

refrigerant oil, leading to component failure.

|

|

|

|

Adding excessive amounts of dye can damage the A/C compressor.

|

|

|

|

PAG oil is water soluble, so condensation on the evaporator core

or the refrigerant lines may wash the PAG oil and fluorescent dye

away from the actual leak. Condensation may also carry dye through

the HVAC module drain.

|

|

|

|

After checking and repairing leaks, thoroughly clean any residual

dye from the areas where leaks were found. Use GLO-AWAY dye cleaner,

from Tracerline®, and hot water to remove the dye (follow the instructions

on the bottle). Residual dye stains can cause misdiagnosis of any

future A/C system leaks.

|

|

|

|

If any refrigerant dye contacts an exterior paint surface, remove

it by doing this:

|

|

|

-

|

Carefully wash the affected surfaces to remove any dirt,

and to prevent paint scratching.

|

|

|

-

|

Mix water and isopropyl alcohol in a 50/50 mixture. Soak

a soft 100 % cotton towel with the water/alcohol mixture,

and place the cloth on the affected areas to remove the

dye.

|

|

|

-

|

After removing the dye with the water/alcohol-soaked

cloth, carefully wash the affected areas, and check that

there is no remaining dye.

|

|

|

|

1.

|

With the engine OFF, use a halogen leak detector first to detect the

leak source. Follow a continuous path in order to ensure that you will not

miss any possible leaks. Test the following areas of the system for leaks:

|

|

|

Possible Leak Area

|

Diagnostic Procedure with the Leak Detector

|

Notes

|

|

Service ports

|

|

|

Check the service ports with caps installed

|

|

|

|

If the detector ‘‘sniffs’’ a

leak, use fluorescent dye to confirm it

|

|

|

When capping the service ports, ensure that the seals

on the port caps are in place, and that the caps are tight.

The caps are used as the final seals in the system

|

|

A/C condenser

|

If the detector ‘‘sniffs’’ a leak, use fluorescent

dye to confirm it

|

|

|

Check for joints or connections coated

with oily dust

|

|

|

|

Check for damaged and corroded areas

|

|

|

|

Check all fittings, couplings, brazed/welded

areas and areas around attachment points

|

|

|

|

Move the probe slowly (1 in/second or

less), and keep it within 1/4 in of the

component being checked. This maximizes

the chance of detecting a leak

|

|

|

|

If you detect a leak, blow compressed

air over the area, then recheck for leaks.

For large leaks, clearing the area with

compressed air may help you pinpoint the

leak source

|

|

|

|

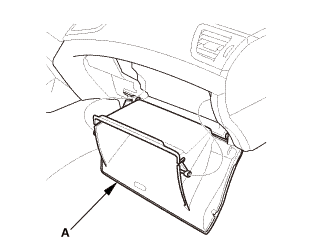

Evaporator

|

|

|

Check at the evaporator drain hose

|

|

|

|

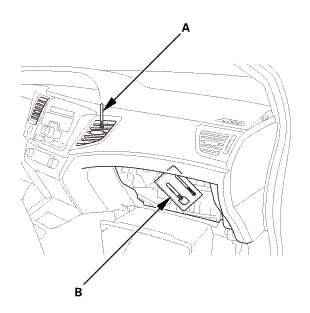

Check at the passenger's side vent and

turn the blower on low speed

|

|

|

|

|

A/C lines

|

|

|

Wiggle the rubber hoses when checking

crimped metal ends

|

|

|

|

If the detector ‘‘sniffs’’ a

leak, use fluorescent dye to confirm it

|

|

|

|

|

Check all fittings, couplings, pressure

switches, brazed/welded areas, and areas

around attachment points on A/C lines and

components

|

|

|

|

Check for damaged and corroded areas

|

|

|

|

Move the probe slowly (1 in/second or

less), and keep it within 1/4 in of the

component being checked. This maximizes

the chance of detecting a leak

|

|

|

|

|

|

|

8.

|

Run the engine and A/C system for 15 minutes to thoroughly circulate

the dye. Then shut the engine off, and inspect the following areas of the

system for leaks:

|

|

NOTE:

|

|

|

Check for leaks in a dark work area, and use the UV light

and the special glasses from the leak check kit. Other UV

lights may not work well with the Tracer-Stick® dye.

|

|

|

|

Small leaks may take up to 1 week of vehicle operation

(with normal A/C use) to become visible.

|

|

|

|

|

Possible Leak Area

|

Diagnostic Procedure with Fluorescent Dye

|

|

Service ports

|

If a leak is found, replace the cap/O-ring seal or A/C

line as needed

|

|

A/C lines

|

|

|

Use a permanent marker pen to circle

the leak area

|

|

|

|

If a leak is found, remove and replace

the A/C line

|

|

|

|

A/C condenser

|

|

|

If a leak is found, remove the A/C condenser

|

|

|

|

Determine whether leak is in the A/C

condenser or the receiver/dryer

|

|

|

|

Use a permanent marker pen to circle

the leak area

|

|

|

|

Replace either the receiver/dryer, or

the A/C condenser, depending upon which

is leaking

|

|

|

|

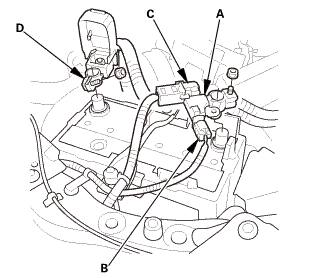

A/C compressor

|

|

|

Check for leaks at all of the A/C compressor

joints, the clutch center, the A/C compressor

front housing bolts, and the scroll bolts

on the back of the A/C compressor

|

|

|

|

If a leak is found, use a permanent marker

pen to circle the leak area

|

|

|

|

If the A/C compressor relief valve appears

to be leaking, determine whether the leak

is coming from the relief valve, or the

joint between the A/C compressor casing

and the valve. If the leak is from the relief

valve, check the A/C system pressures, and

refer to the pressure test table in the

A/C system test. If the leak is from the

casing/valve joint, replace the A/C compressor

relief valve

|

|

|

|

If the leak is coming from the suction

hose and/or discharge hose fittings on the

A/C compressor, clean the A/C fittings and

replace the suction/discharge fitting O-rings

|

|

|

|

For all other A/C compressor leaks, remove

and replace the A/C compressor

|

|

|

|

Evaporator

|

|

|

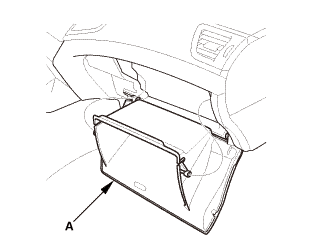

Start checking for evaporator leaks by

illuminating the evaporator drain tube area

|

|

|

|

If a leak is found, remove the evaporator

core

|

|

|

|

Determine whether leak is from evaporator

or expansion valve

|

|

|

|

Use a permanent marker pen to circle

leak area

|

|

|

|

Replace the expansion valve, or the evaporator

core, depending upon which is leaking

|

|

|

|

|

|

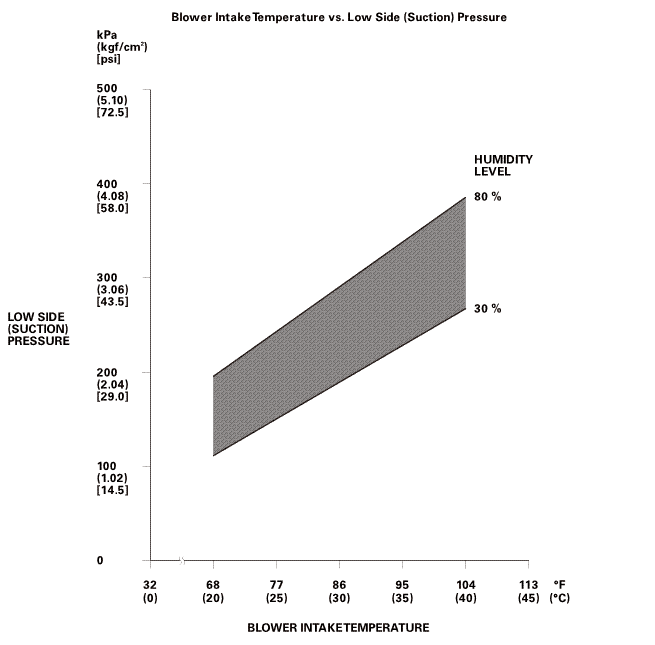

mm7.2mmmm12mmum

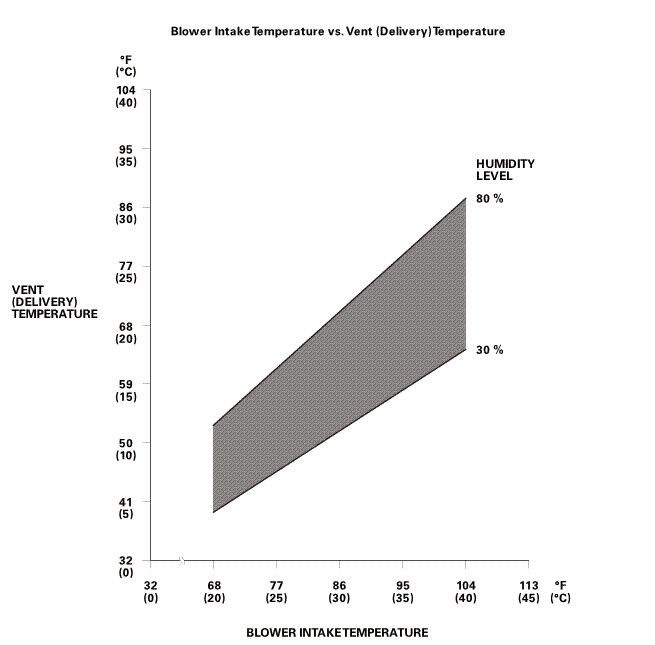

mm7.2mmmm12mmum orhuullnrrvlevel11vmrsono):277-rin)ian)amwinintaketemperature

orhuullnrrvlevel11vmrsono):277-rin)ian)amwinintaketemperature sun:highnuwuomlevel2217-s

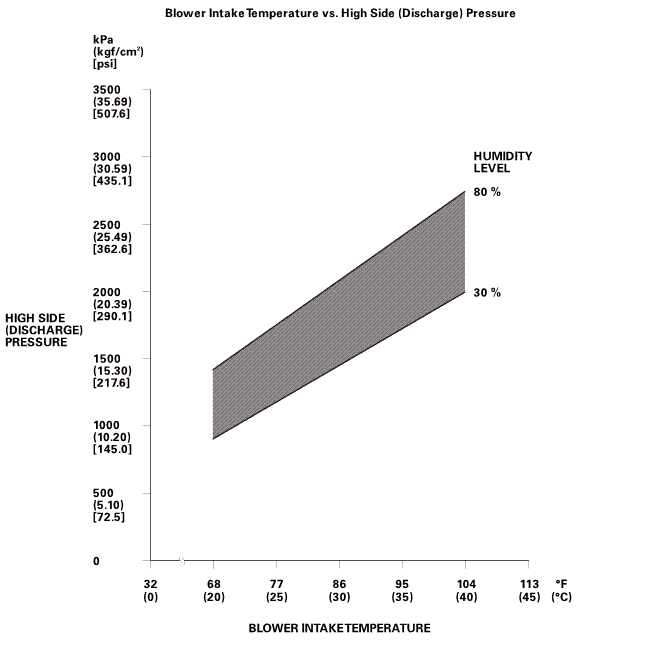

sun:highnuwuomlevel2217-s turn(suction)snnhuuunrrvlevel(sucnomzoo(am[am77-r(ulam

turn(suction)snnhuuunrrvlevel(sucnomzoo(am[am77-r(ulam Compressor

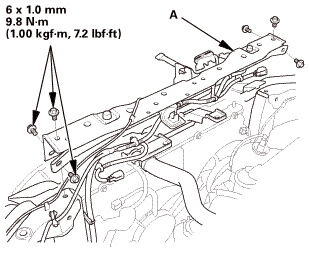

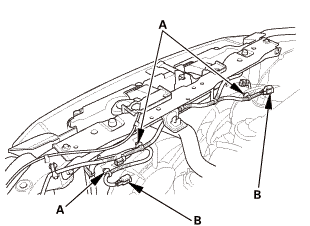

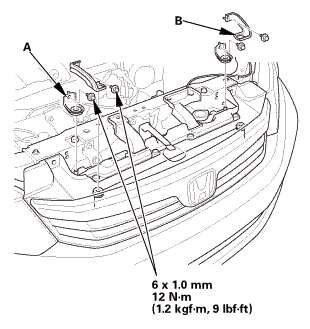

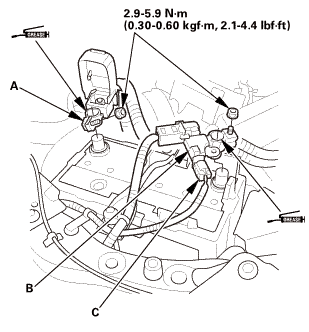

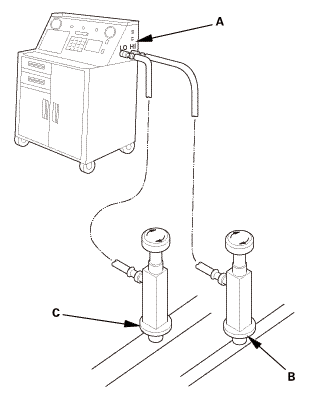

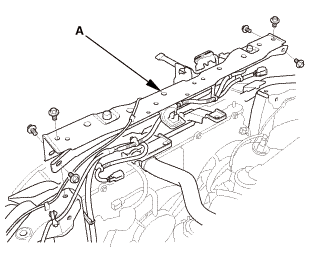

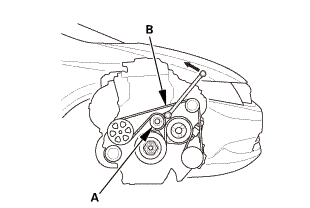

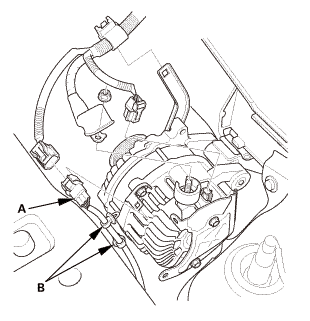

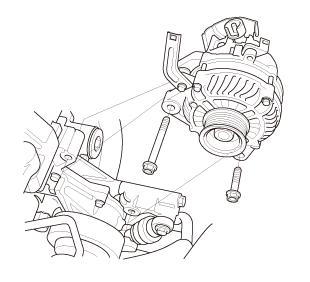

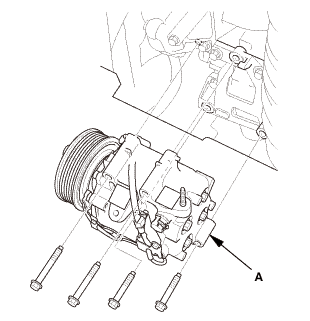

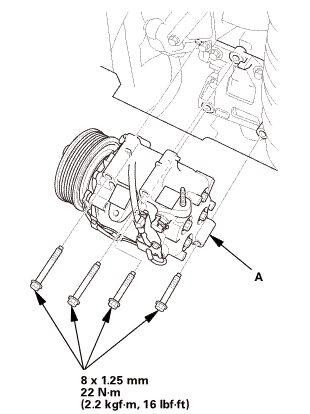

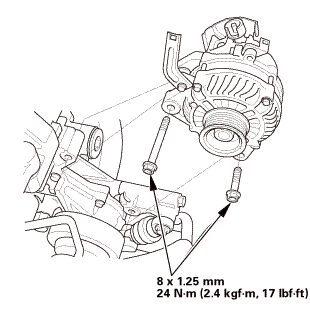

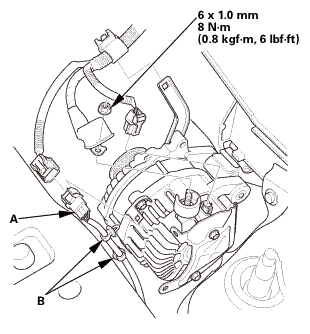

Compressor A/C Compressor Removal and Installation (K24Z7)

A/C Compressor Removal and Installation (K24Z7)

mmn-m(2

mmn-m(2 i.nmm(n.i

i.nmm(n.i