Honda Civic Service Manual: M/T Countershaft Assembly Clearance Inspection (K24Z7)

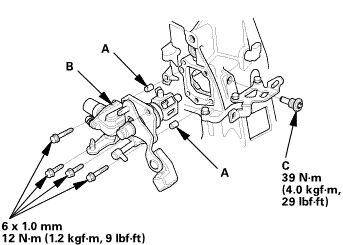

Removal

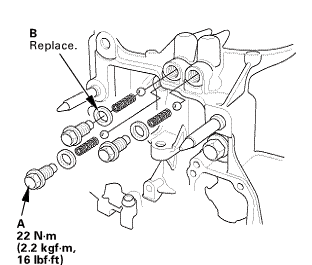

| 1. | M/T Change Lever Assembly |

|

|

|

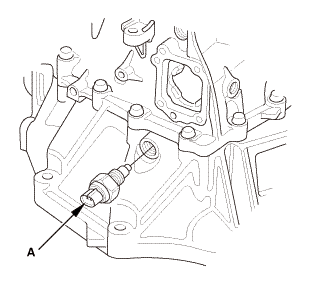

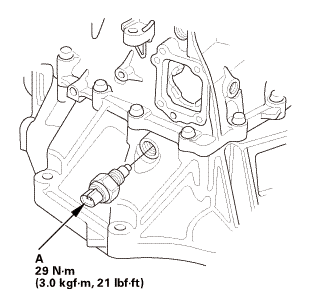

| 2. | Back-Up Light Switch |

|

|

|

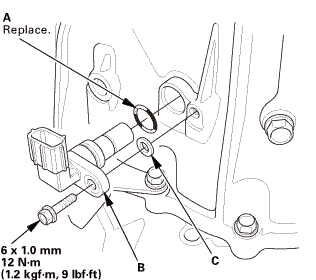

| 3. | Output Shaft (Countershaft) Speed Sensor |

|

|

|

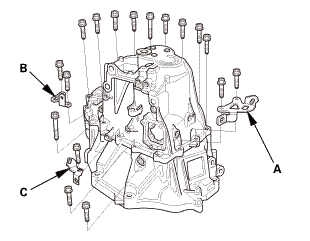

| 4. | Transmission Housing |

|

|

|

|

|

|

|

|

|

|

|

|

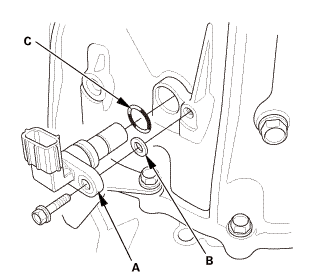

| 5. | Reverse Shift Fork |

|

|

|

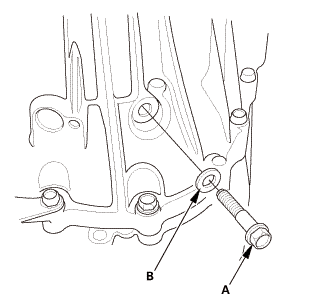

| 6. | Baffle Plate |

|

|

|

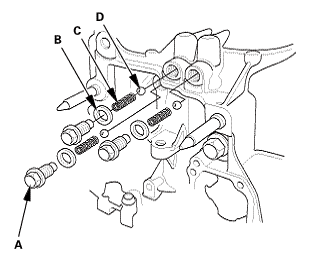

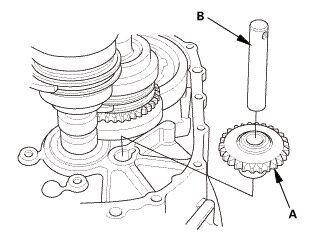

| 7. | Reverse Idler Gear |

|

|

|

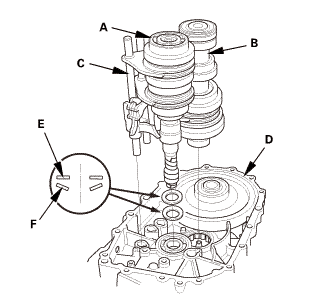

| 8. | M/T Mainshaft and Countershaft and Shift Fork Assembly |

|

|

|

|||||||||||||||

Inspection

Inspection

|

NOTE: Before inspection, make sure the special bolt is tightened to the specified torque. |

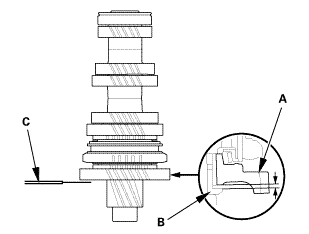

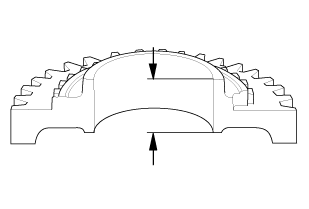

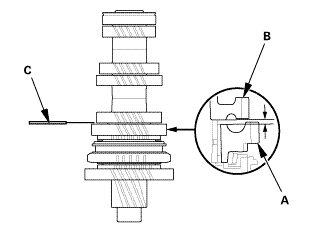

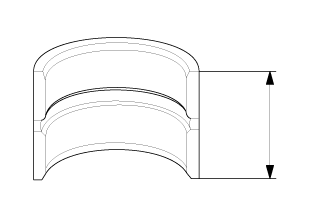

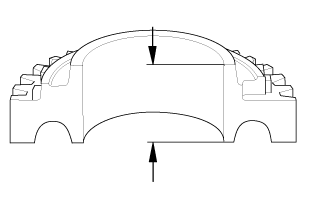

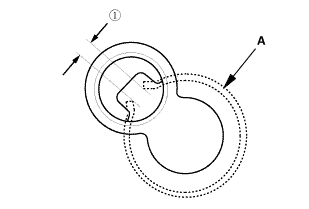

| 1. | Countershaft Assembly Clearance Inspection |

|

|

|

|||||||||||||||||||||||

|

|

|

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

||||||||||||

|

|

|

|||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

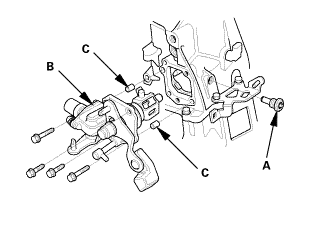

Installation

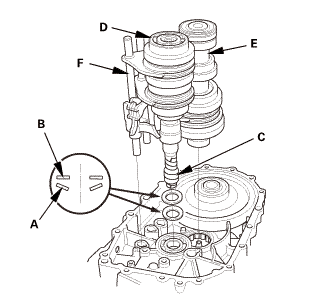

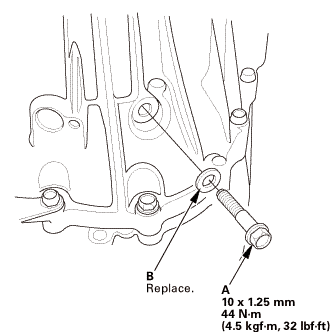

| 1. | M/T Mainshaft and Countershaft and Shift Fork Assembly |

|

|

|

||||||||||||||||||

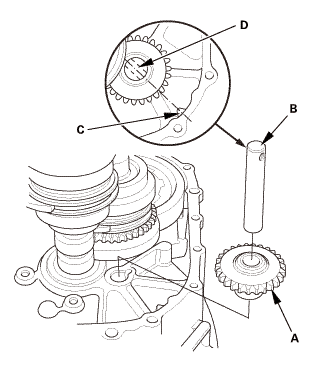

| 2. | Reverse Idler Gear |

|

|

|

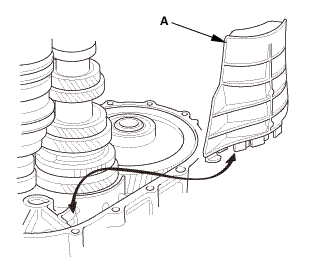

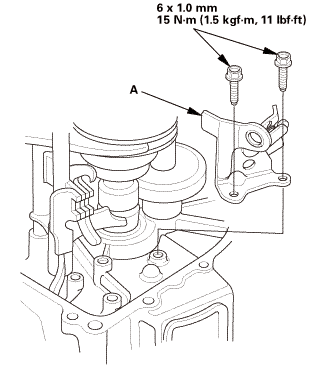

| 3. | Baffle Plate |

|

|

|

| 4. | Reverse Shift Fork |

|

|

|

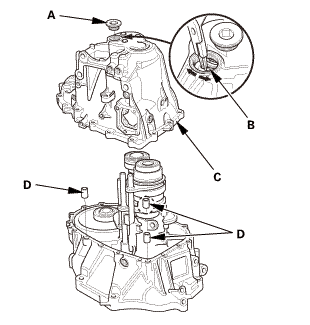

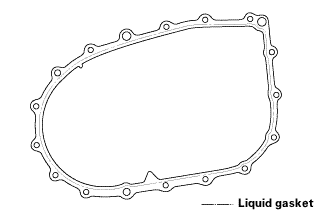

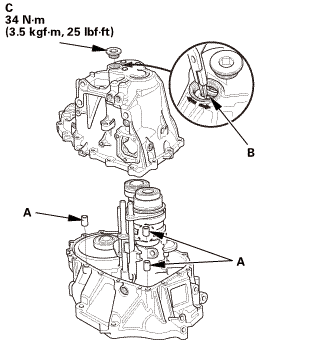

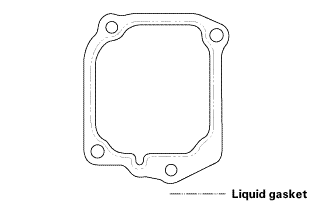

| 5. | Transmission Housing |

|

|

|

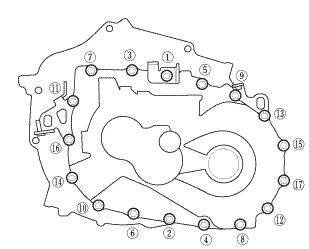

||||||||||||||||||||

|

|

|

|||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

| 6. | Output Shaft (Countershaft) Speed Sensor |

|

|

|

| 7. | Back-Up Light Switch |

|

|

|

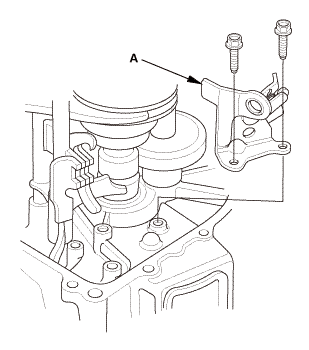

| 8. | M/T Change Lever Assembly |

|

|

|

||||||||||||||||||||

|

|

|

M/T Countershaft Assembly Clearance Inspection (R18Z1 M/T)

M/T Countershaft Assembly Clearance Inspection (R18Z1 M/T)

Removal

1.

M/T Change Lever Assembly

1.

Remove the change lever assembly (A).

...

See also:

Honda Civic Owners Manual. Customer Service Information

Honda dealership personnel are trained professionals who should be able to

deal

with any problems you may encounter with your vehicle. If, however, you are

faced

with a problem that they cannot resolve to your satisfaction, contact Honda

Customer Services.

U.S. Owners

American Honda Motor C ...

mmlbf!

mmlbf!

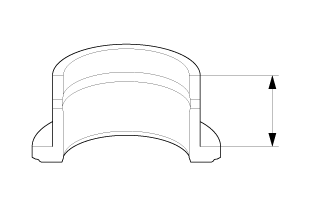

as installed:

3.3-6.0 mm (0.130-0.236 in)

as installed:

3.3-6.0 mm (0.130-0.236 in)

iukn

iukn