Honda Civic Service Manual: Heater Unit/Core Removal and Installation (With A/C)

|

||

|

||

|

|

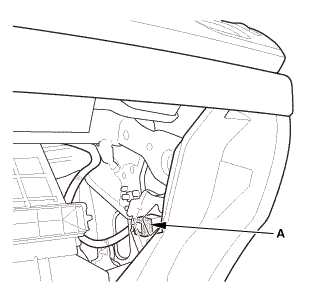

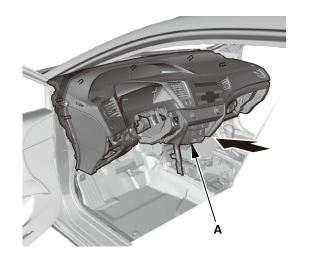

SRS components are located in this area. Review the SRS component locations and the precautions and procedures before doing repair or servicing. |

|

NOTE: |

|

|||

|

| 1. | Vehicle Lift |

|

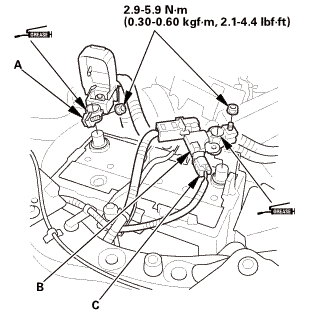

| 2. | Battery Terminal (SRS) - Disconnection |

|

|

|

||||||||||||||||||||||||||||||

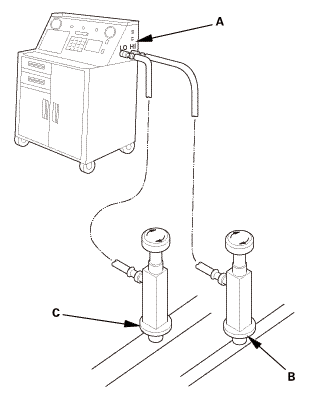

| 3. | R-134a Refrigerant Recovery/Recycling/Charging Station - Connection |

|

|

|

| 4. | A/C Refrigerant - Recovery |

|

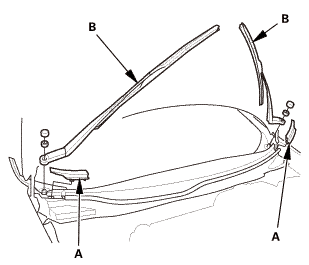

| 5. | Wiper Arm Assembly (K24Z7 engine) |

|

|

|

| 6. | Both Side Cowl Covers (K24Z7 engine) |

|

|

|

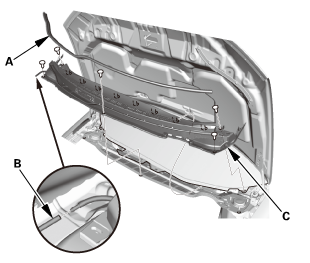

| 7. | Center Cowl Cover (K24Z7 engine) |

|

|

|

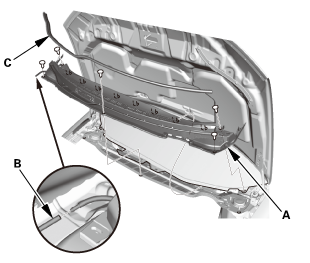

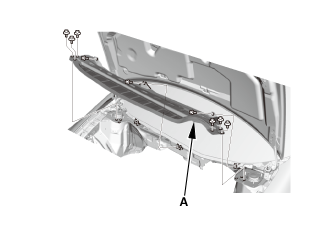

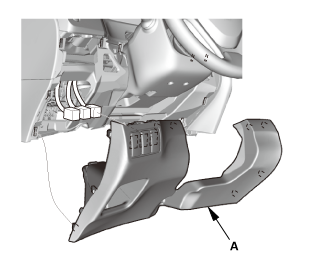

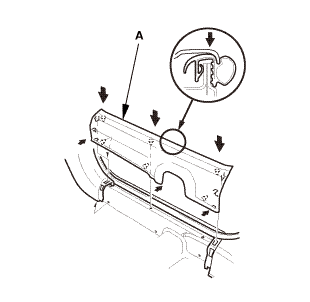

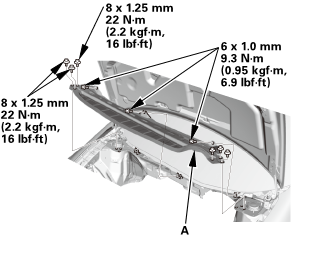

| 8. | Under-Cowl Panel (K24Z7 engine) |

|

|

|

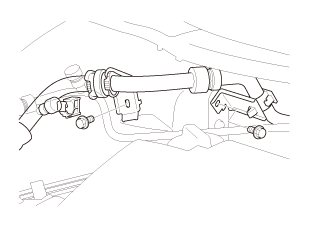

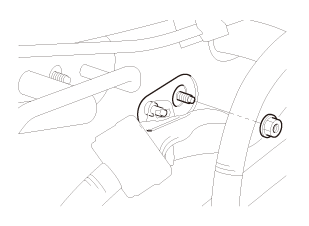

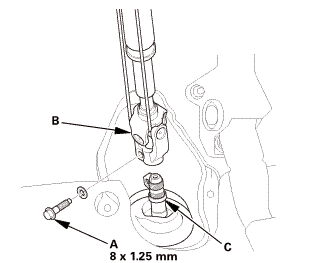

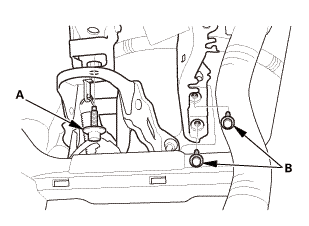

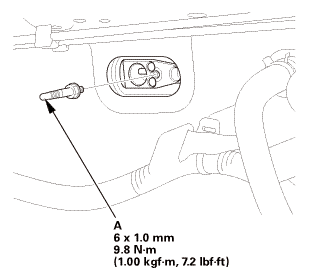

| 9. | A/C Line - Evaporator Side |

|

Except K24Z7 engine

|

|

|

K24Z7 engine

|

|

|

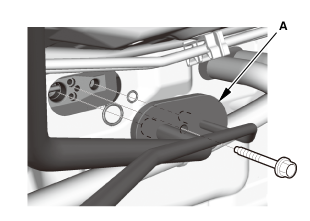

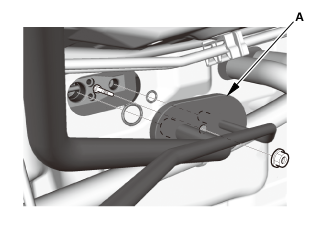

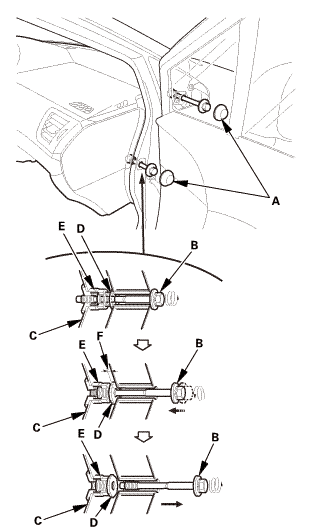

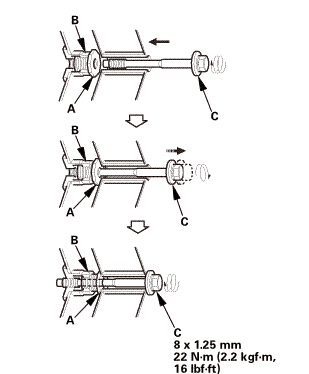

Flange bolt type

Stud bolt type

|

|

|

|

|

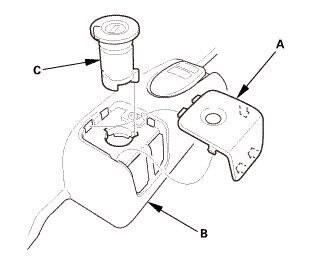

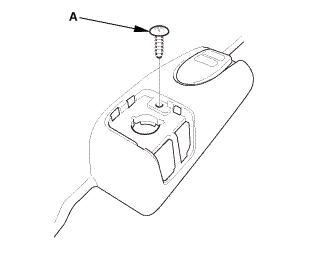

| 10. | Radiator Cap |

|

| 11. | Radiator Coolant - Replacement |

|

|

|

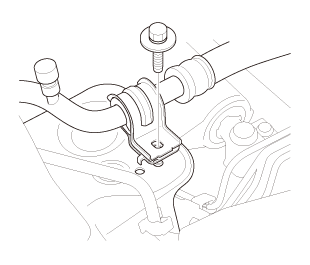

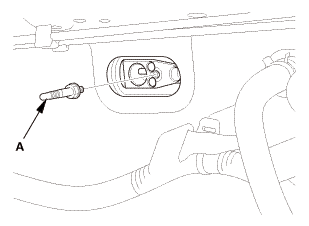

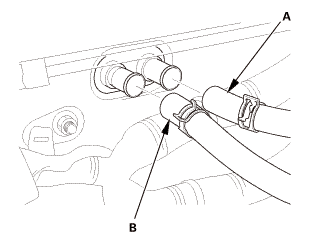

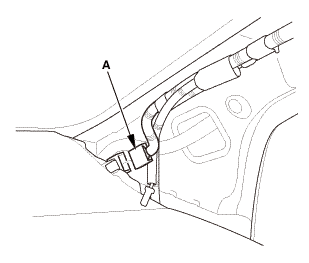

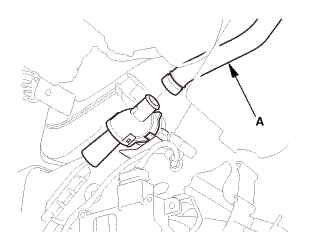

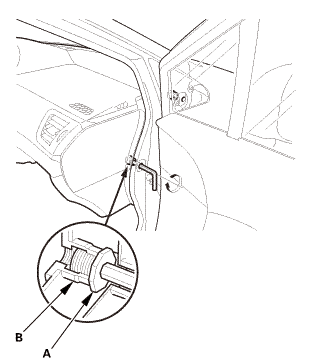

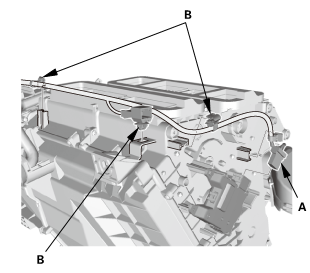

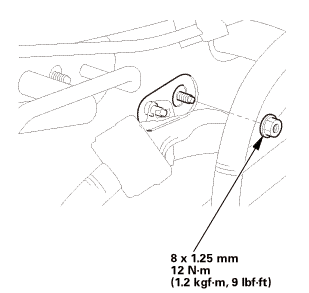

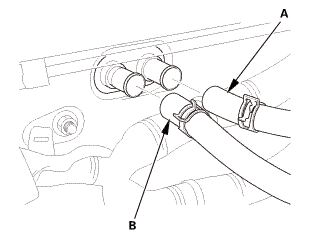

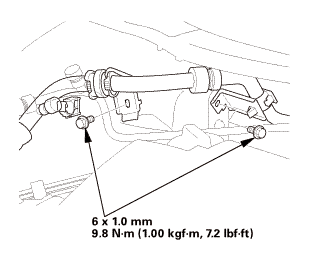

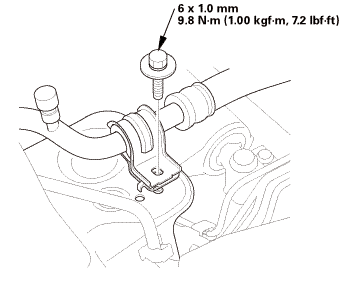

| 12. | Heater Hose - Body Side |

|

|

|

|

|

|

||||||

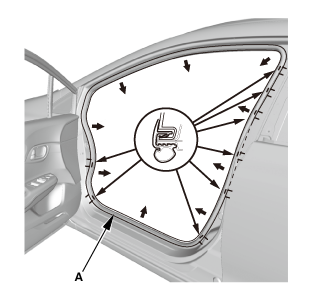

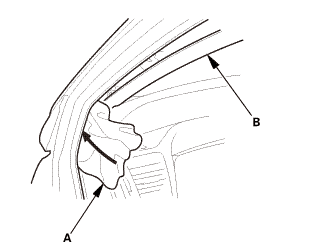

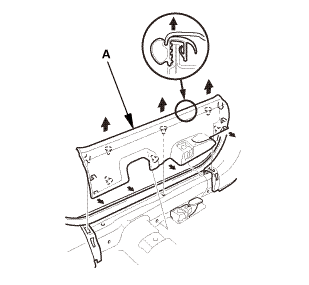

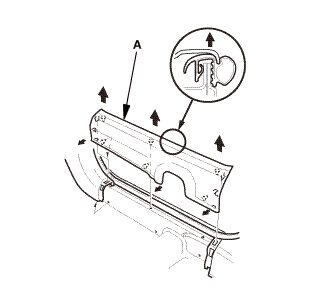

| 13. | Front Door Opening Seal As Needed Both |

|

|

|

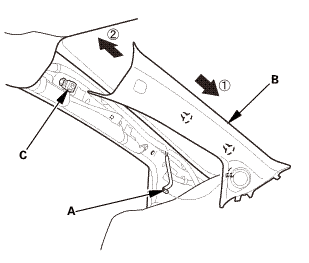

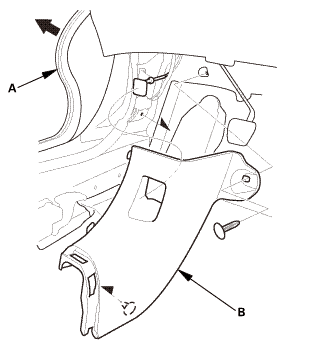

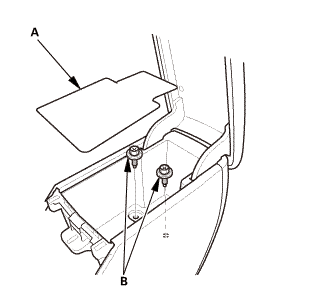

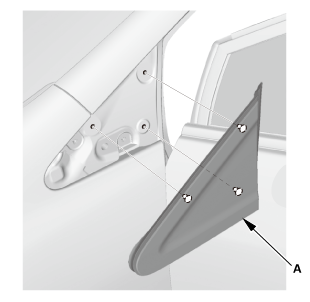

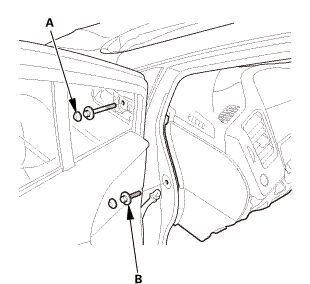

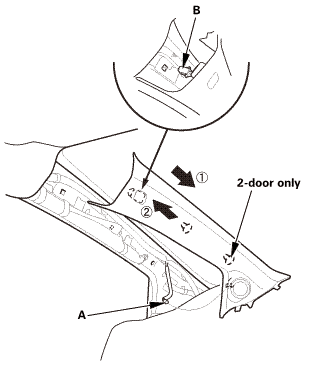

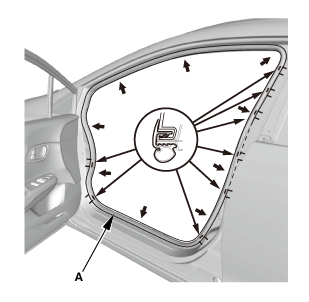

| 14. | A-Pillar Trim Both |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

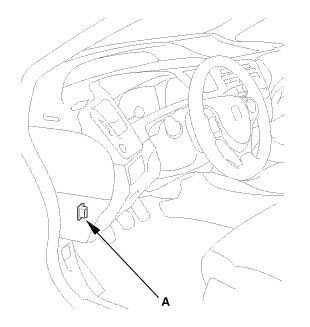

| 15. | Driver's Dashboard Lower Cover |

|

|

|

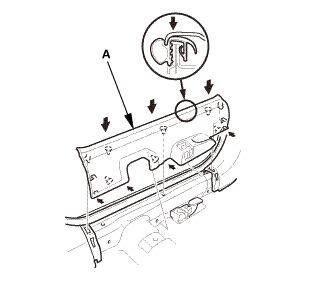

| 16. | Both Front Door Sill Trims |

|

|

|

|

|

|

|

Driver's side

Passenger's side

|

|

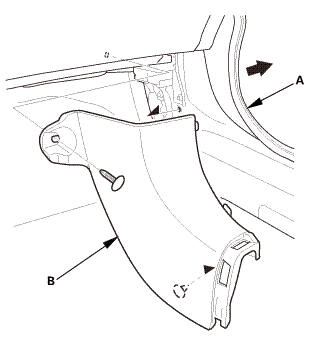

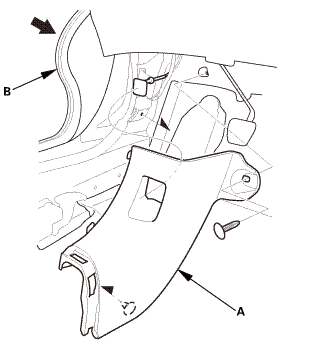

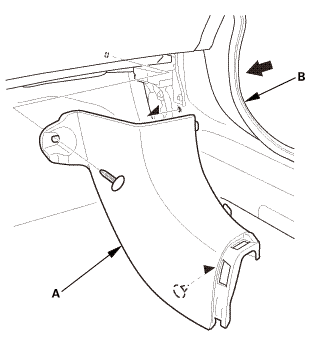

| 17. | Both Kick Panels |

|

Driver's side

Passenger's side

|

|

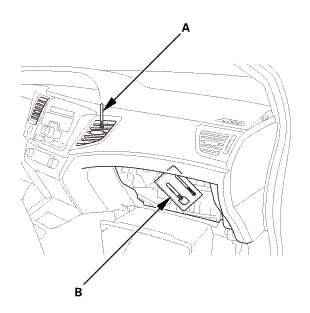

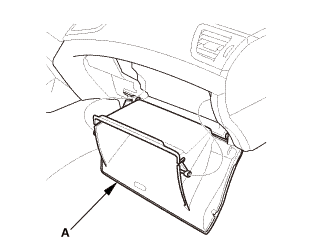

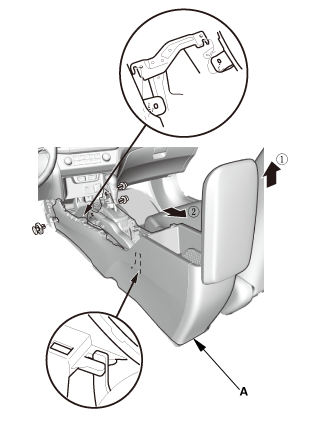

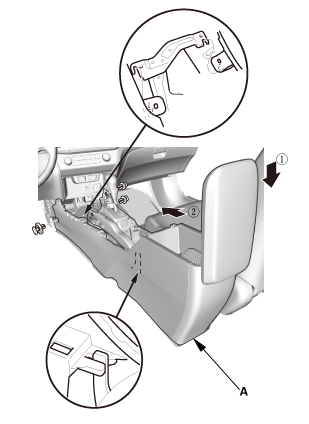

| 18. | Glove Box - Move |

|

|

|

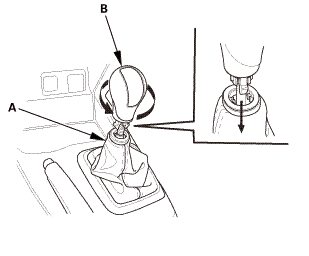

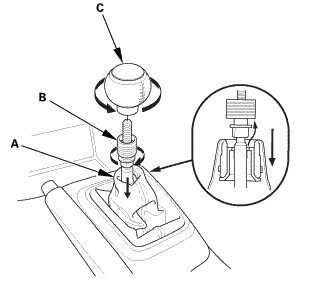

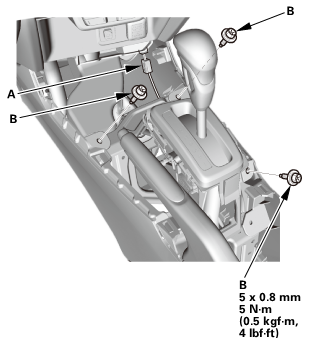

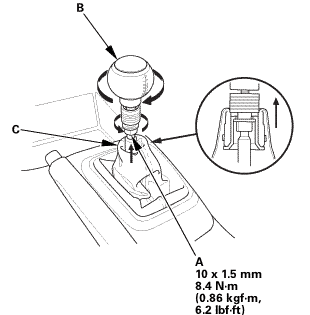

| 19. | M/T Shift Lever Knob |

|

Except K24Z7 engine

|

|

|

K24Z7 engine

|

|

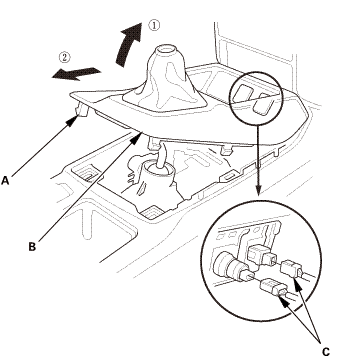

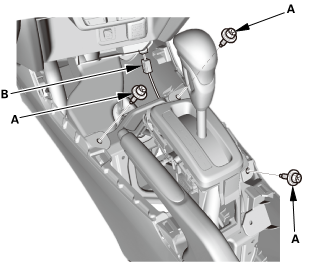

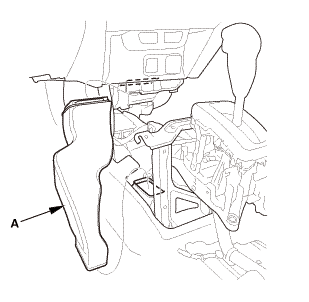

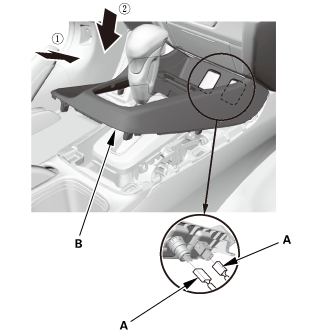

| 20. | Center Console Panel |

|

|

|

| 21. | Center Console Panel Assembly (Except '12M M/T) |

|

|

|

|

|

|

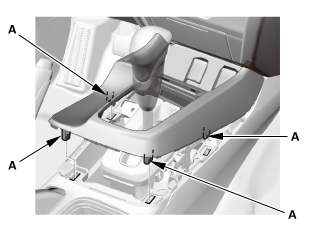

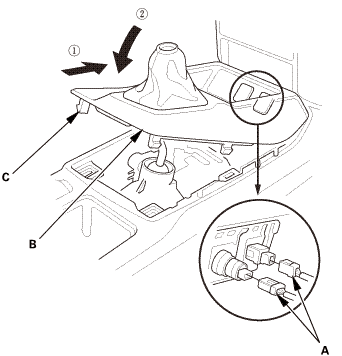

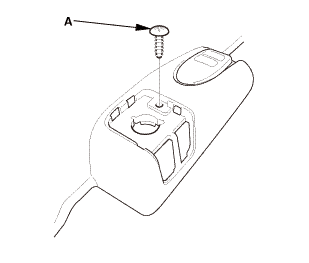

| 22. | Cup Holder Panel Assembly |

|

|

|

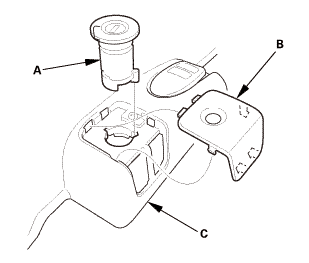

| 23. | Center Console |

|

|

|

|

|

|

|

|

|

|

|

|

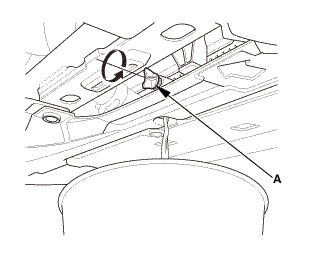

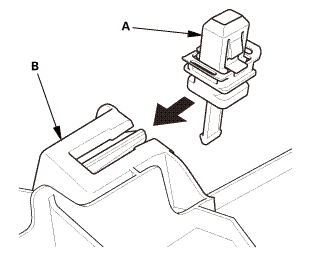

| 24. | Rear Heater Joint Duct |

|

|

|

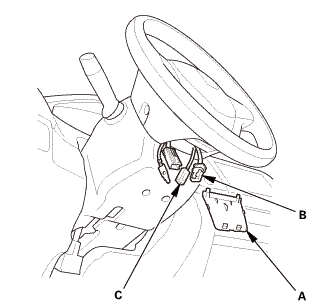

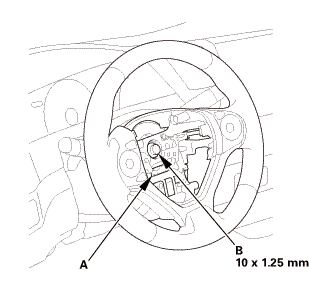

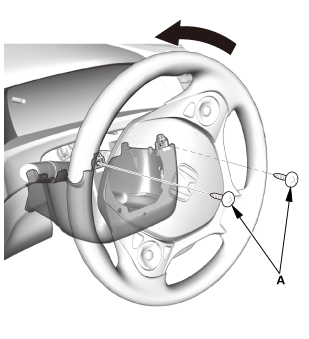

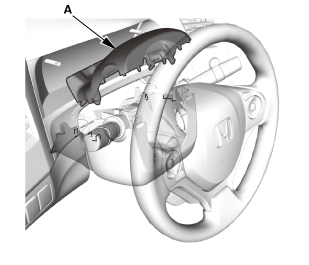

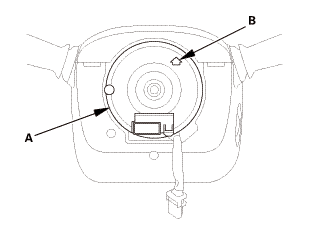

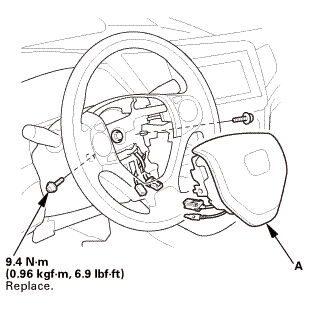

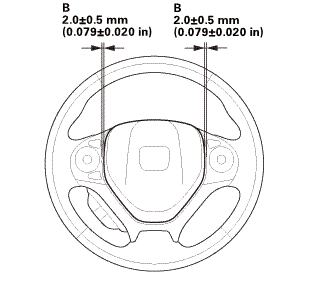

| 25. | Driver's Airbag |

|

|

|

|

|

|

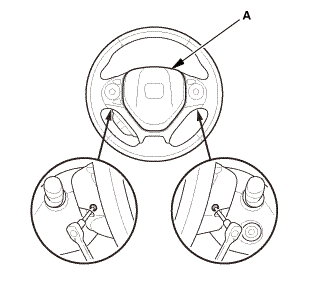

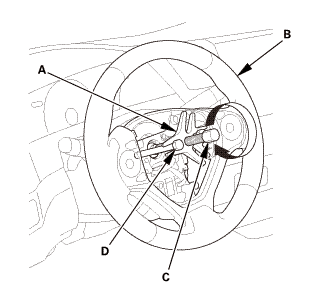

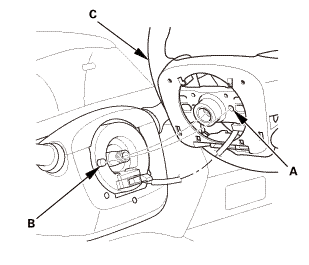

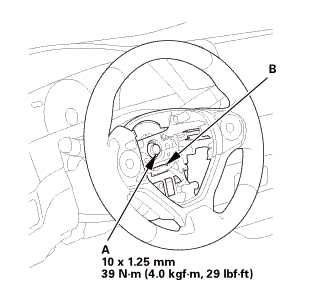

| 26. | Steering Wheel Assembly |

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

| 27. | Upper Column Cover |

|

|

|

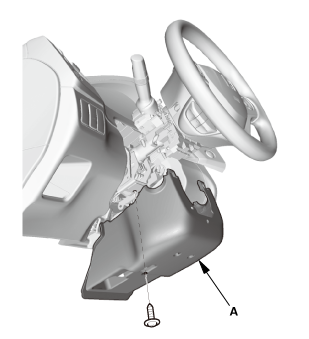

| 28. | Lower Column Cover |

|

|

|

|

|

|

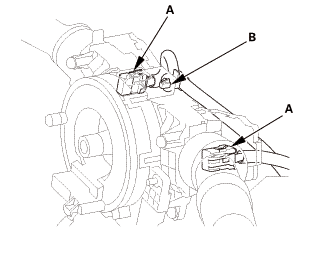

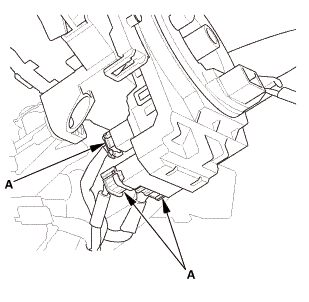

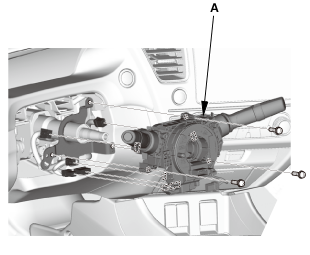

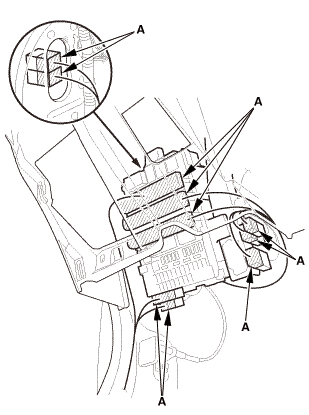

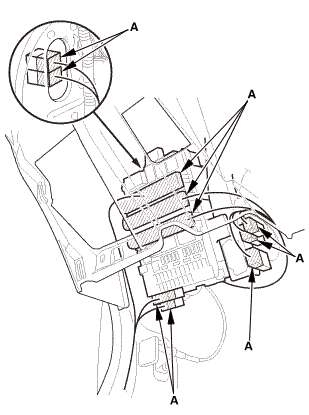

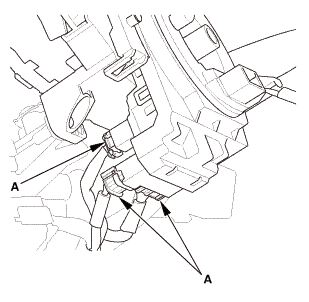

| 29. | Combination Switch Body Assembly |

|

|

|

|

|

|

|

Without steering lock

With steering lock

|

|

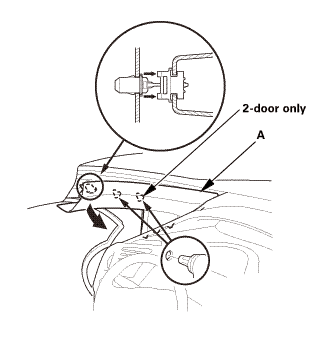

| 30. | Steering Joint Cover |

|

|

|

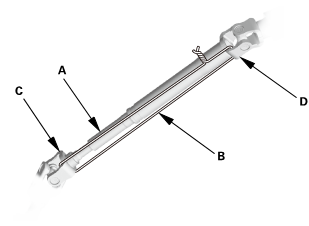

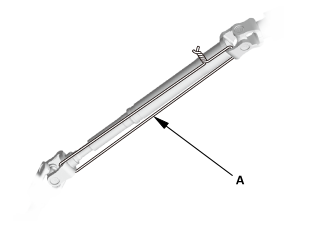

| 31. | Steering Column Lower Slide Shaft - Hold |

|

|

|

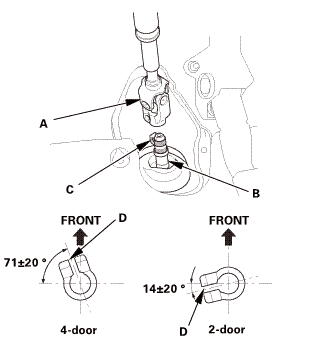

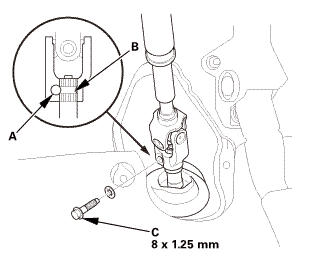

| 32. | Steering Joint - Disconnection |

|

|

|

||||||||||||||||||||

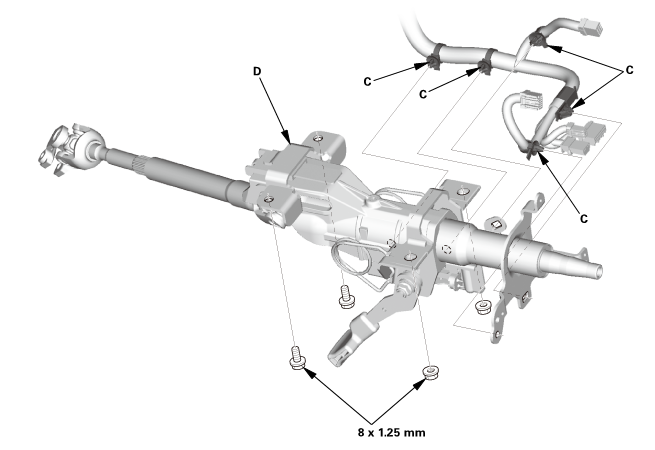

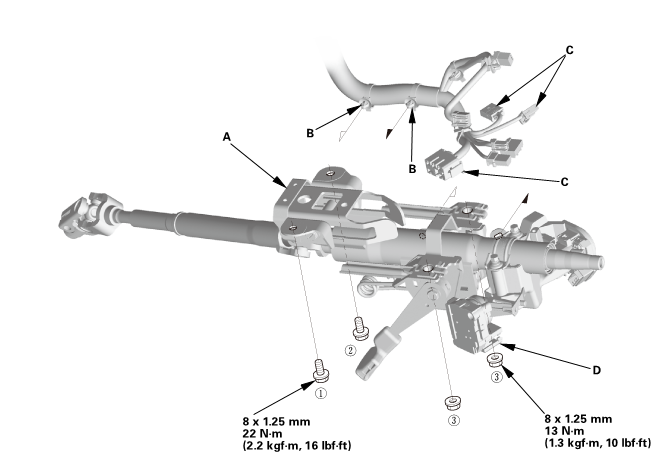

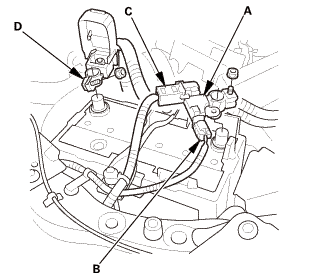

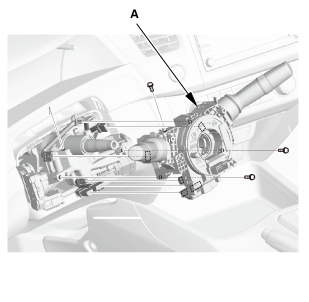

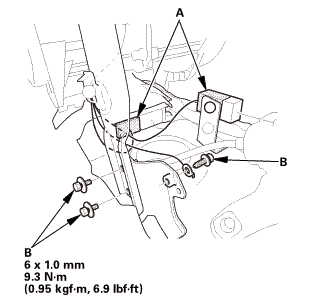

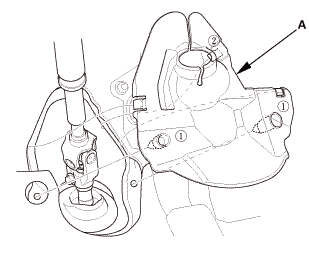

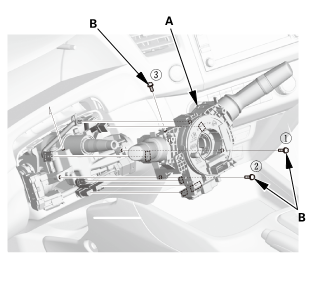

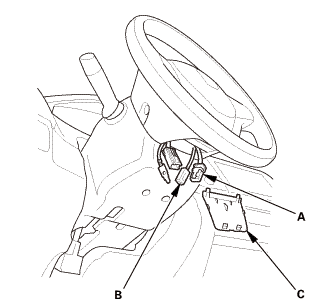

| 33. | Steering Column |

|

1. |

With steering lock: Disconnect the connectors (A) from the ignition switch (B). |

Without steering lock

With steering lock

|

2. |

Detach the wire harness clips (C) from the steering column. |

|

3. |

Remove the steering column (D). |

|

|

NOTE: Do not release the lock lever until the steering column is installed. If the lock lever is released before installation, adjust the steering column after installation. |

||

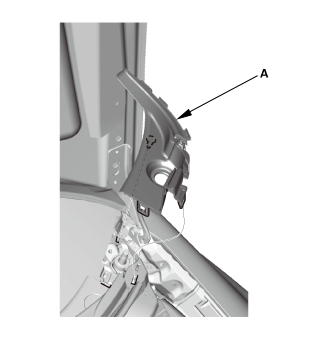

| 34. | A-Pillar Corner Trim Both |

|

|

|

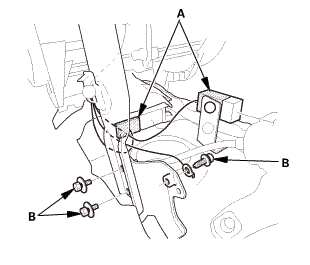

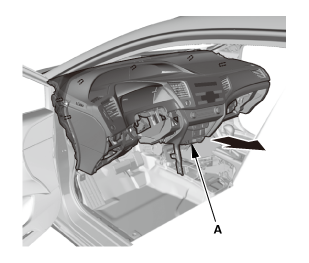

| 35. | Dashboard/Steering Hanger Beam |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

| 36. | Blower-Heater Unit |

|

|

|

|

|

|

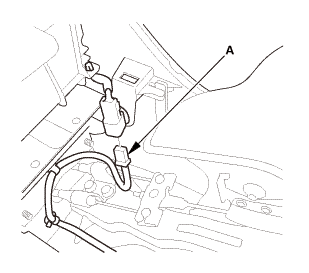

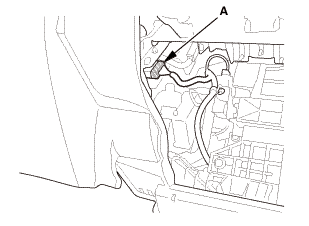

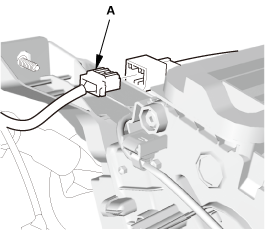

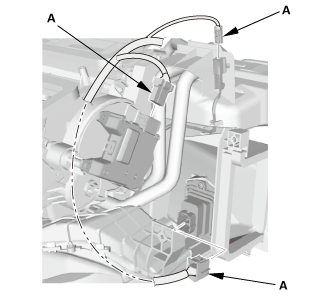

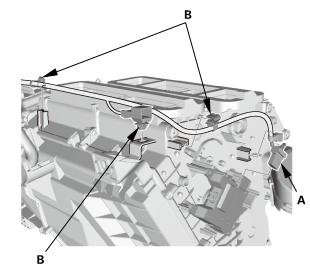

| 37. | A/C Wire Harness |

|

|

|

|

|

|

|

|

|

|

|

|

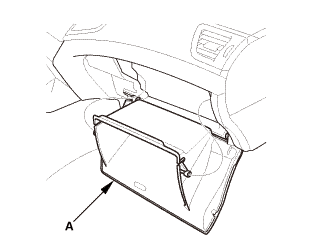

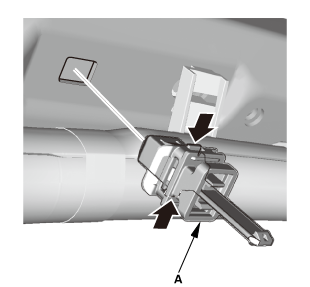

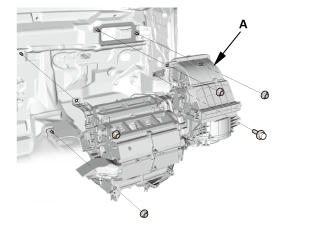

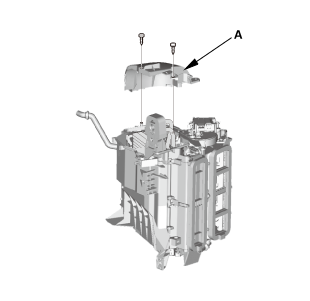

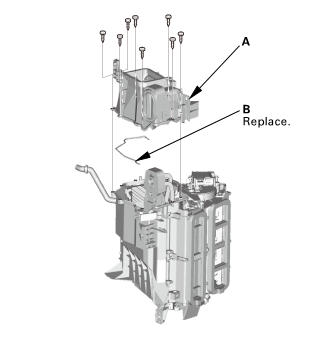

| 38. | Blower Unit |

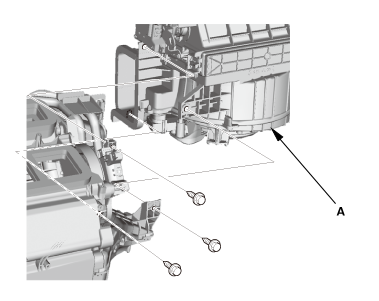

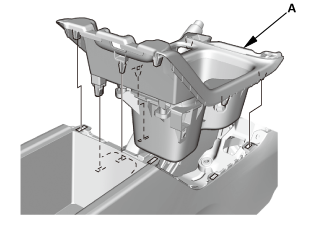

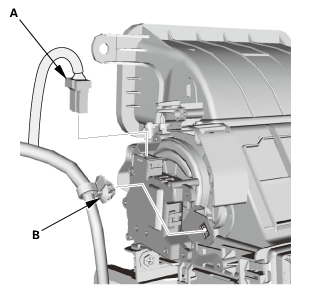

|

1. |

Remove the blower unit (A). |

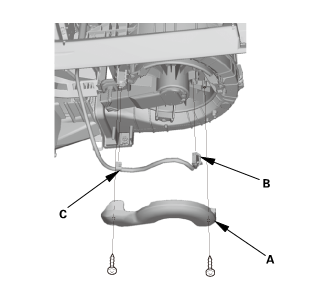

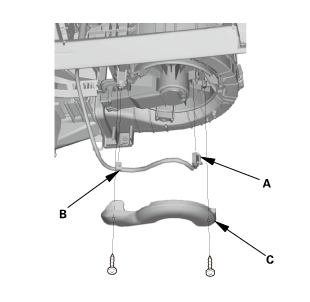

| 39. | Passenger's Heater Duct |

|

|

|

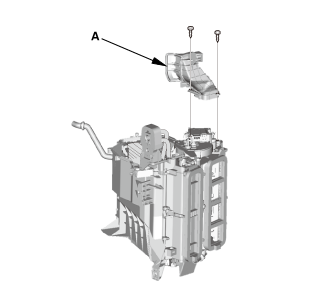

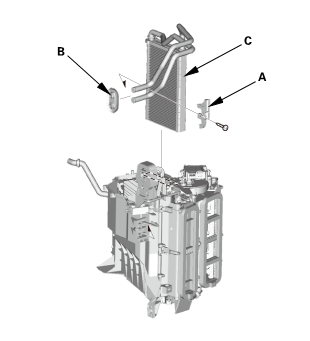

| 40. | Heater Core Cover |

|

|

|

| 41. | Expansion Valve Cover |

|

|

|

| 42. | Heater Core |

|

|

|

|

||

|

||

|

||

|

|

SRS components are located in this area. Review the SRS component locations and the precautions and procedures before doing repair or servicing. |

|

NOTE: |

|

|||

|

|||

|

|||

|

|||

|

|||

|

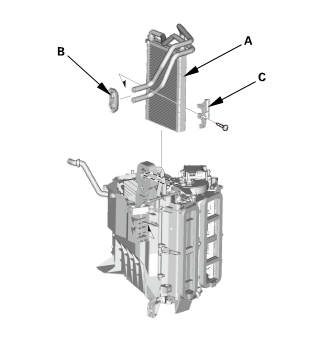

| 1. | Heater Core |

|

|

|

| 2. | Expansion Valve Cover |

|

|

|

| 3. | HEATER CORE COVER |

|

|

|

| 4. | Passenger's Heater Duct |

|

|

|

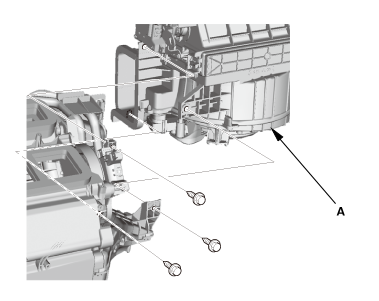

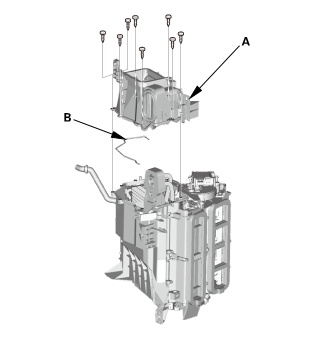

| 5. | Blower Unit |

|

1. |

Install the blower unit (A). |

| 6. | A/C Wire Harness |

|

|

|

|

|

|

|

|

|

|

|

|

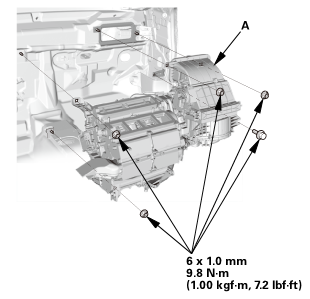

| 7. | Blower-Heater Unit |

|

|

|

|

|

|

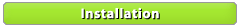

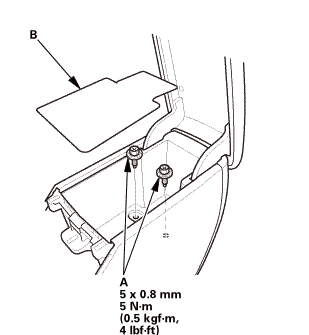

| 8. | Dashboard/Steering Hanger Beam |

|

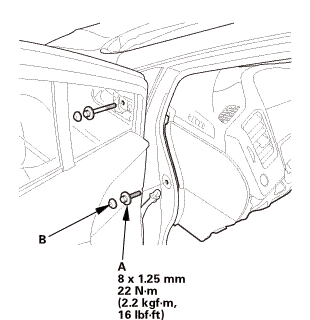

Special bolt tightening on passenger's side

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 9. | A-Pillar Corner Trim Both |

|

|

|

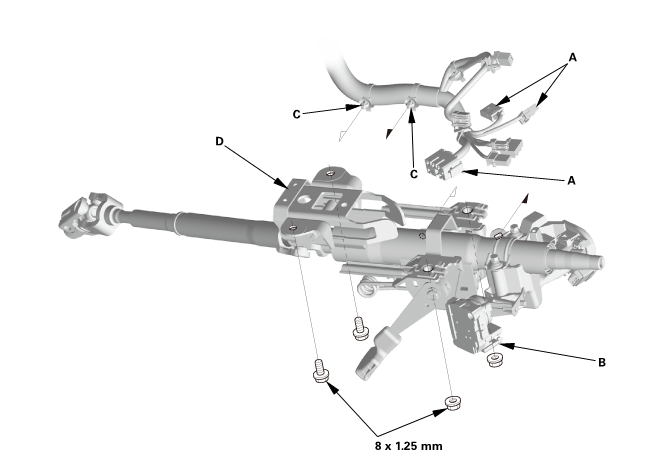

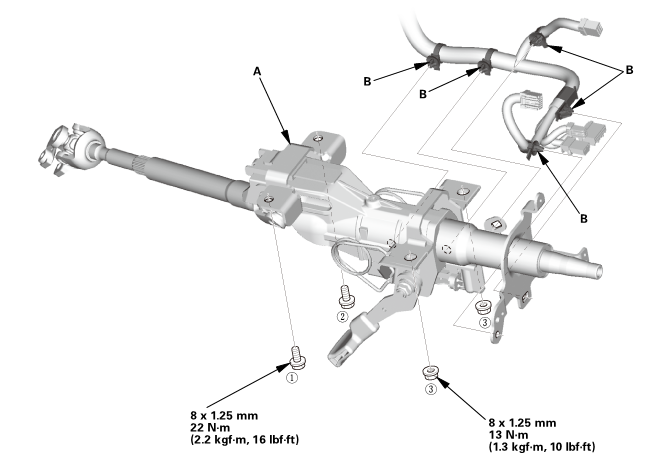

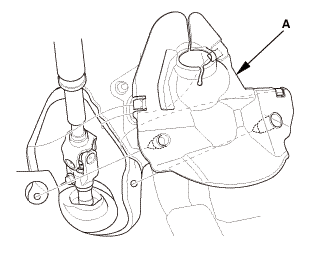

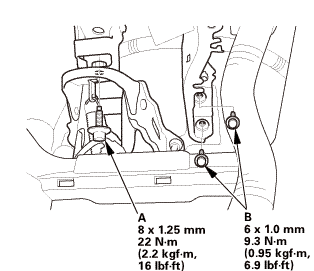

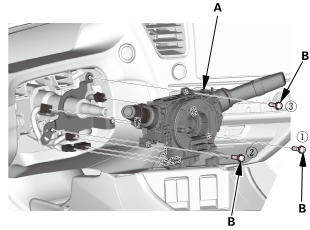

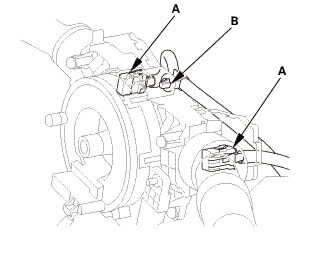

| 10. | Steering Column |

|

1. |

Install the steering column (A). |

|

|

NOTE: Do not release the lock lever until the steering column is installed. If the lock lever is released before installation, adjust the steering column after installation. |

||

Without steering lock

22(22mm)

22(22mm)

With steering lock

u.

u.

|

2. |

Loosely tighten the attaching nuts and bolts. |

|

3. |

Tighten the attaching nuts and bolts to the specified torque in the sequence shown. |

|

4. |

Install the wire harness clips (B) to the steering column. |

|

5. |

With steering lock: Connect the connectors (C) to the ignition switch (D). |

| 11. | Steering Joint - Reconnection |

|

|

|

||||||||||||||||||||

|

|

|

| 12. | Steering Column Lower Slide Shaft - Release |

|

|

|

| 13. | Steering Joint Cover |

|

|

|

| 14. | Combination Switch Body Assembly |

|

Without steering lock

With steering lock

|

|

|

|

|

|

|

|

| 15. | Lower Column Cover |

|

|

|

|

|

|

| 16. | Upper Column Cover |

|

|

|

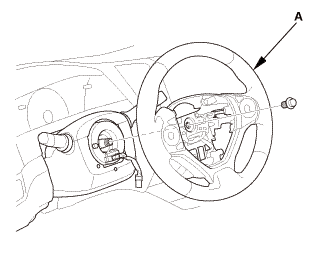

| 17. | Steering Wheel Assembly |

|

|

|

|

|

|

|||||||||

|

|

|

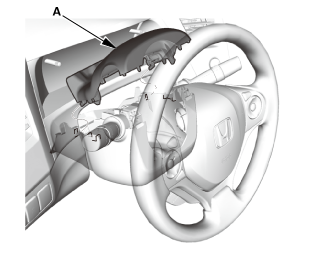

| 18. | Driver's Airbag |

|

|

|

||||||||||

|

|

|

||||||||||||

| 19. | Rear Heater Joint Duct |

|

|

|

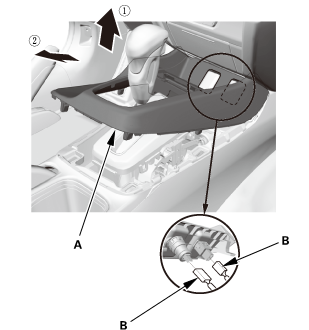

| 20. | Center Console |

|

|

|

|

|

|

|

|

|

|

|

|

| 21. | Cup Holder Panel Assembly |

|

|

|

| 22. | Center Console Panel Assembly (Except '12M M/T) |

|

|

|

|

|

|

| 23. | Center Console Panel |

|

|

|

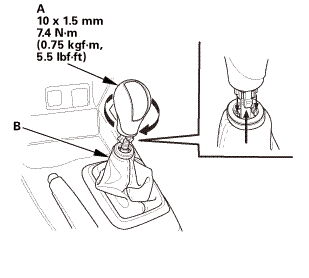

| 24. | M/T Shift Lever Knob |

|

Except K24Z7 engine

|

|

|||||||||

|

K24Z7 engine

|

|

| 25. | Both Kick Panels |

|

Driver's side

Passenger's side

|

|

| 26. | Both Front Door Sill Trims |

|

Driver's side

Passenger's side

|

|

|

|

|

|

|

|

| 27. | Driver's Dashboard Lower Cover |

|

|

|

| 28. | A-Pillar Trim Both |

|

|

|

|

|

|

||||||||||||||||||||||||||||||

| 29. | Front Door Opening Seal as Needed Both |

|

|

|

| 30. | Heater Hose - Body Side |

|

|

|

||||||

|

|

|

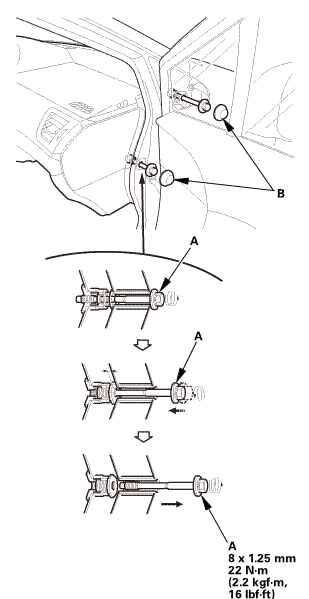

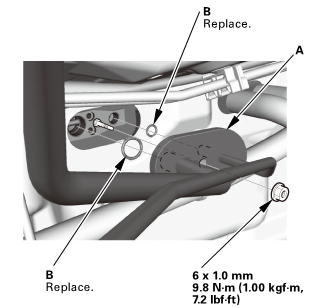

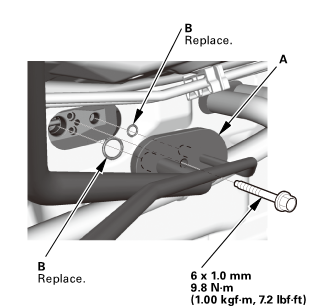

| 31. | A/C Line - Evaporator Side |

|

|

|

|

Stud bolt type

Flange bolt type

|

|

|

Except K24Z7 engine

|

|

|

K24Z7 engine

|

|

| 32. | Under-Cowl Panel (K24Z7 engine) |

|

|

|

| 33. | Center Cowl Cover (K24Z7 engine) |

|

|

|

| 34. | Both Side Cowl Covers (K24Z7 engine) |

|

|

|

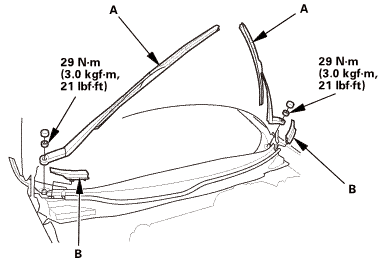

| 35. | Wiper Arm Assembly (K24Z7 engine) |

|

NOTE: Set the wiper arms to the auto-stop position before installation. |

|

1. |

Install the wiper arms (A). |

25u....in

25u....in

|

2. |

Install the cowl top wiper covers (B). |

| 36. | Battery Terminal (SRS) - Reconnection |

|

|

|

|||||||||||||||||||

| 37. | Radiator Coolant - Replacement |

|

1. |

Follow the chart and pour coolant into the radiator up to the base of the filler neck. |

|||||||||||||||||||||||||||||||||||||

|

NOTE: |

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

*: When you want to winterize the coolant with the minimum amount of coolant change but the current coolant concentration in the vehicle is unknown, you must drain all coolant from the cooling system. |

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

| 38. | A/C System Evacuation |

|

| 39. | A/C Refrigerant - Charging |

|

1. |

Charge the system with the specified amount of R-134a refrigerant. Do not overcharge the system; the A/C compressor will be damaged. |

||||||||

|

Select the appropriate units of measure for your refrigerant charging station. |

|||||||||

|

|||||||||

| 40. | A/C Refrigerant - Leak Check |

|

Leak Detector Usage Tips (Refer to the Operator's Manual for complete operating instructions) |

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

|||

|

Fluorescent Dye Usage Tips |

|

||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||

|

||||||||||||

|

|

1. |

With the engine OFF, use a halogen leak detector first to detect the leak source. Follow a continuous path in order to ensure that you will not miss any possible leaks. Test the following areas of the system for leaks: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2. |

Close the quick coupler valves, then disconnect the quick couplers from the vehicle service ports. |

|

3. |

Attach the universal connect set, from the Optimax Jr. Leak Detection Kit, to the service valve fitting. Close the control valve (the black knob on the connect set). |

|

4. |

Attach the charging station low pressure hose quick coupler to the service valve fitting, and open the quick coupler valve. Evacuate the connect set using the charging station vacuum pump, then close the quick coupler valve. |

|

5. |

Detach the universal connect set, and install a Tracer-Stick® dye capsule between the connect set and the service valve fitting (see the manufacturer's instructions for more detail). |

|

6. |

Attach the quick coupler on the universal connect set to the low pressure service port on the vehicle. Open the charging station low pressure hose quick coupler valve, but do not open the control valve. |

|

7. |

Start the engine, and set the A/C system to maximum cooling. Open the control valve to let refrigerant and the dye enter the A/C system through the low pressure service port. Close the control valve when the Tracer-Stick® dye capsule is empty. |

|

8. |

Run the engine and A/C system for 15 minutes to thoroughly circulate the dye. Then shut the engine off, and inspect the following areas of the system for leaks: |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

NOTE: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 41. | HDS DLC - Connection |

|

|

|

| 42. | DTC - Clear |

|

| 43. | Confirm Proper SRS Operation |

|

| 44. | A/C System - Test |

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

6. |

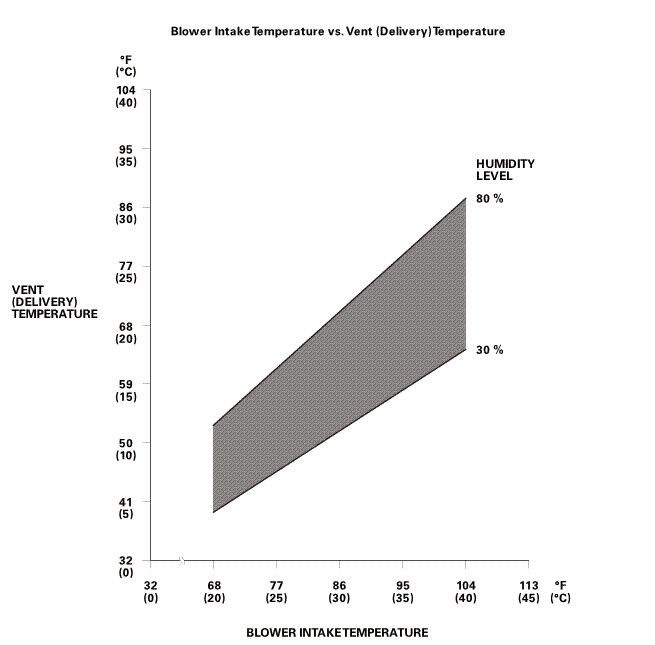

To complete the vent (delivery)/blower intake temperature chart: |

|||||||||||||||||

|

||||||||||||||||||

|

NOTE: The vent (delivery) temperature and blower intake temperature should intersect in the shaded area. Any measurements outside the line may indicate the need for further inspection. |

||||||||||||||||||

orhuullnrrvlevel11vmrsono):277-rin)ian)amwinintaketemperature

orhuullnrrvlevel11vmrsono):277-rin)ian)amwinintaketemperature

|

7. |

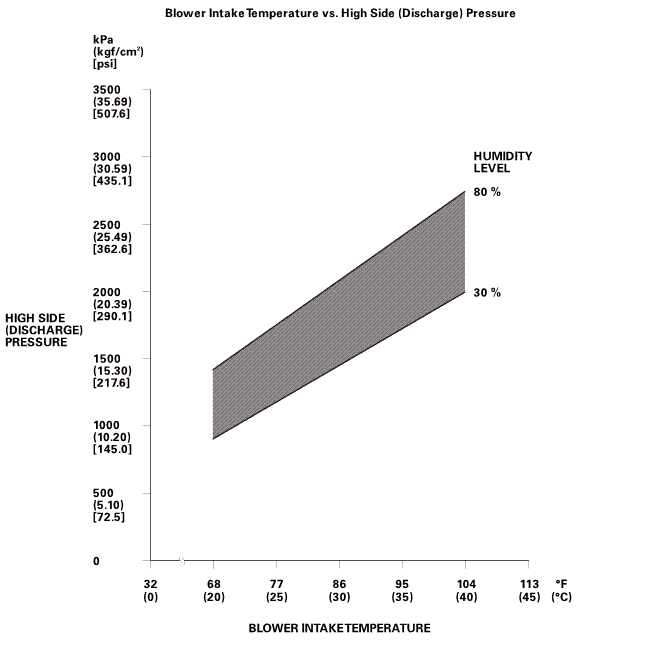

To complete the high side (discharge) pressure/blower intake temperature chart: |

|||||||||||||||||

|

||||||||||||||||||

|

NOTE: The high side (discharge) pressure and blower intake temperature should intersect in the shaded area. Any measurements outside the line may indicate the need for further inspection. |

||||||||||||||||||

sun:highnuwuomlevel2217-s

sun:highnuwuomlevel2217-s

|

8. |

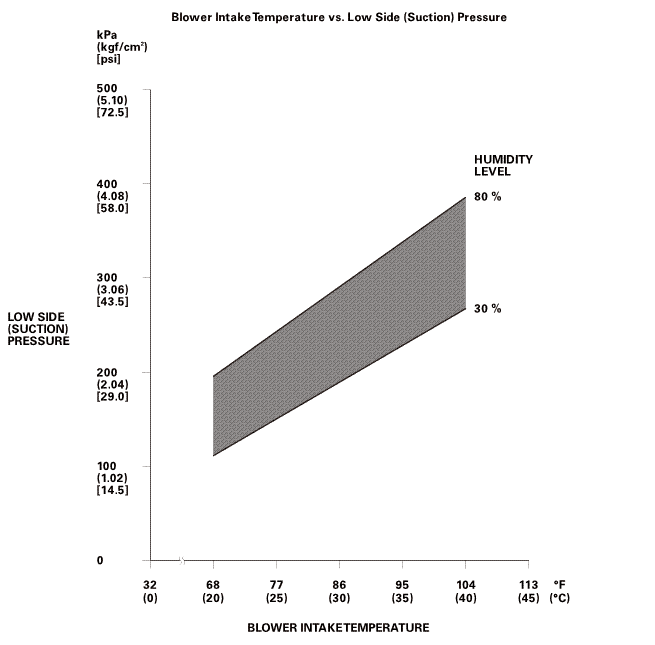

To complete the low side (suction) pressure/blower intake temperature chart: |

|||||||||||||||||

|

||||||||||||||||||

|

NOTE: The low side (suction) pressure and blower intake temperature should intersect in the shaded area. Any measurements outside the line may indicate the need for further inspection. |

||||||||||||||||||

turn(suction)snnhuuunrrvlevel(sucnomzoo(am[am77-r(ulam

turn(suction)snnhuuunrrvlevel(sucnomzoo(am[am77-r(ulam

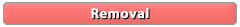

| 45. | Glove Box - Move |

|

|

|

| 46. | VSA Sensor Neutral Position - Memorization |

|

||||||||||

| 47. | Steering Angle Sensor Neutral Position - Clear |

|

|||||||

| 48. | Maintenance Minder Reset |

|

A/C System Inspection

A/C System Inspection

Inspection

1.

A/C System Inspection

checkin!

NOTE: For A/C system noise, go to the A/C System Noise Check.

...

A/C Condenser Removal and Installation ('13)

A/C Condenser Removal and Installation ('13)

1.

Glove Box - Move

1.

Lower the glove box (A).

2.

R-134a Refrigerant Recovery ...

See also:

Honda Civic Owners Manual. Audio System Basic Operation

Models with color audio system

To use the audio system, the ignition switch must be in ACCESSORY

or ON

.

Use the selector knob or MENU/CLOCK

button to access some audio functions.

Press to switch between the

normal and

extended display for some functions.

Selector kn ...

wxusmm

wxusmm

1.0mm[loo

1.0mm[loo mm22(2.2

mm22(2.2

mmmm

mmmm ixi2mm22(2.2asin

ixi2mm22(2.2asin

no

no

mmmmin)in!

mmmmin)in!

mm11(1.1

mm11(1.1

mmmm

mmmm

an

an u)mmn-in(mu

u)mmn-in(mu

(o.2ao.sam.

(o.2ao.sam.