Honda Civic Service Manual: Camshaft Inspection (R18Z1)

|

|

1.

|

Raise the vehicle on a lift, and make sure it is securely supported.

|

|

| 2. |

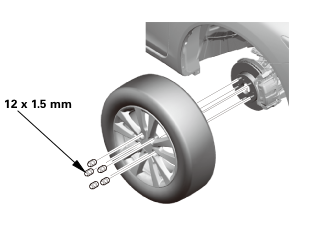

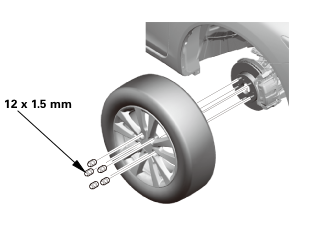

Tire and Wheel-Removal, Front Right |

|

12x1mm 12x1mm

|

|

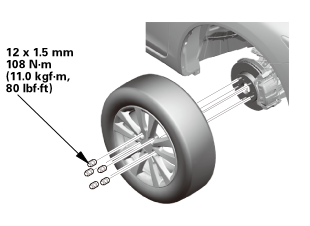

1.

|

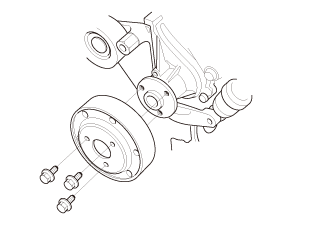

Remove the right front wheel.

|

|

|

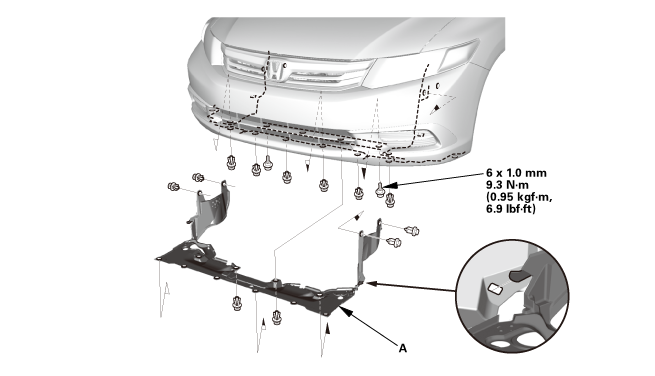

1.

|

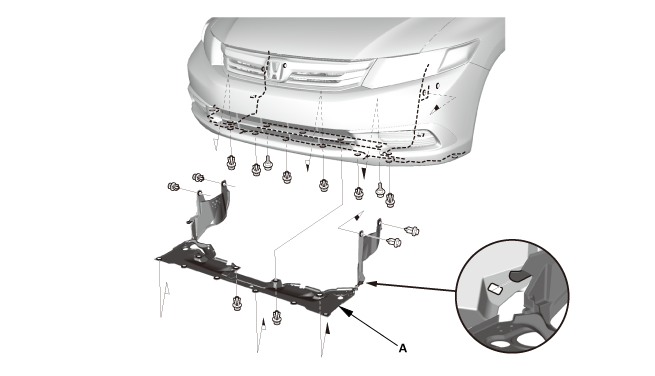

Remove the splash shield (A).

|

| 4. |

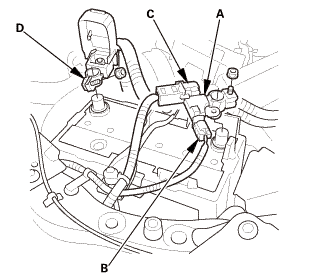

Battery Terminal - Disconnection |

|

|

|

1.

|

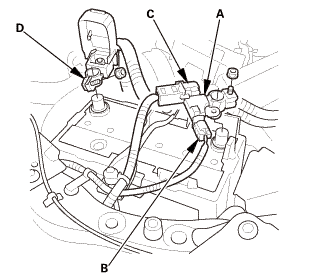

Make sure the ignition switch is in LOCK (0), or the vehicle

ignition in the OFF mode.

|

|

2.

|

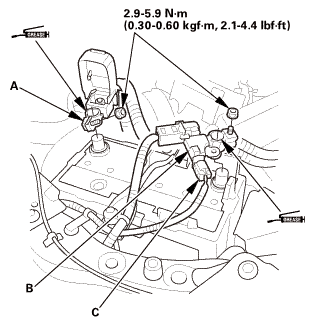

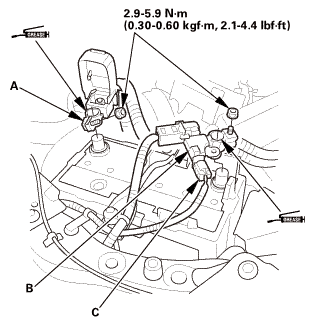

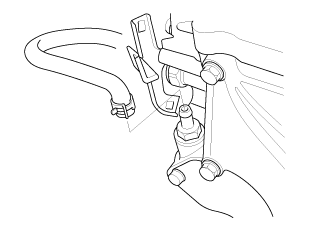

Disconnect and isolate the negative cable with the battery sensor

(A) from the battery.

|

|

NOTE:

|

|

|

Always disconnect the negative side first.

|

|

|

|

To protect the battery sensor connector (B) from

damage, do not hold it when removing the negative

terminal.

|

|

|

|

Do not disconnect the battery sensor from the

negative terminal (C).

|

|

|

|

3.

|

Disconnect the positive cable (D) from the battery.

|

|

|

|

|

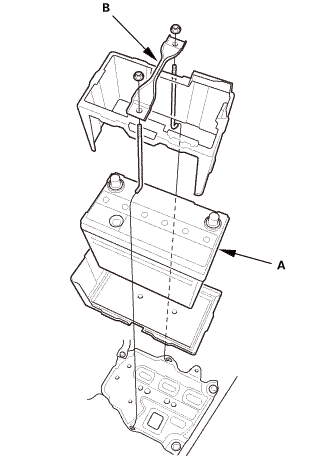

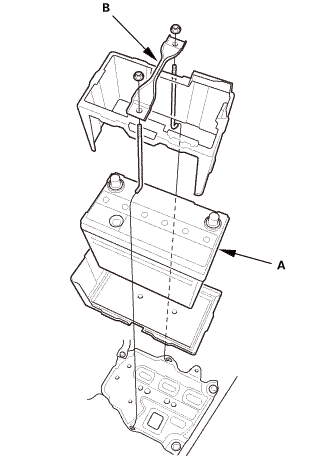

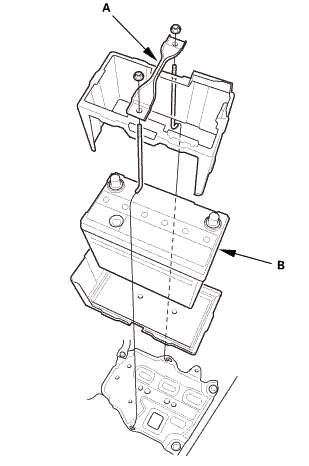

1.

|

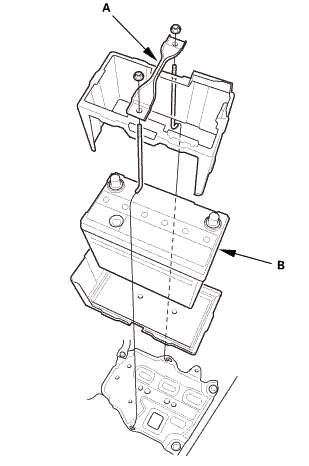

Remove the battery setting plate (A) and the battery (B).

|

|

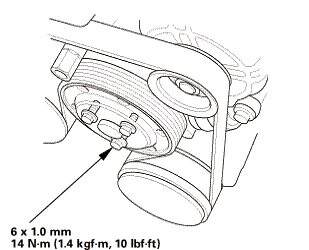

| 6. |

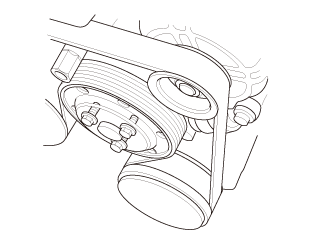

Water Pump Pulley Mounting Bolt - Loosen |

|

|

|

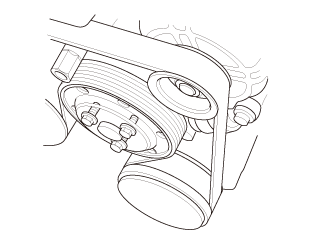

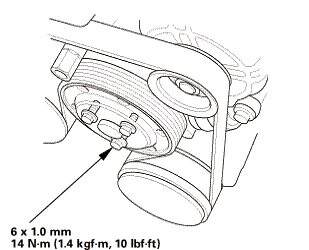

1.

|

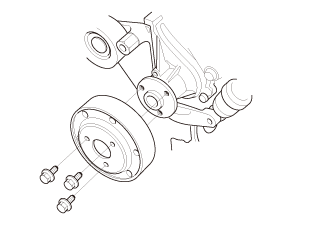

Loosen the water pump pulley mounting bolts.

|

|

|

|

|

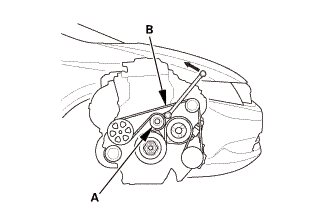

1.

|

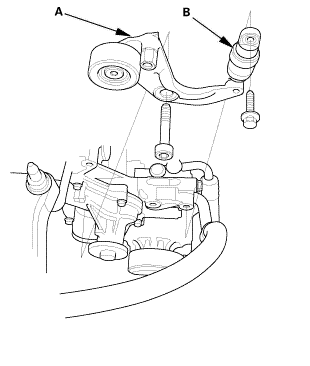

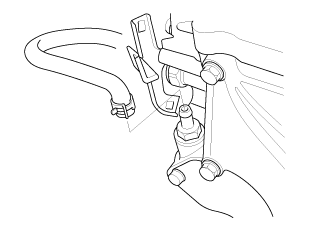

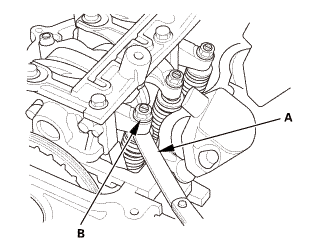

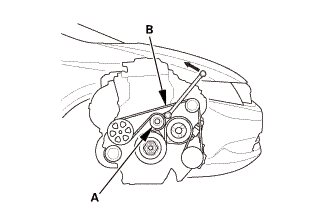

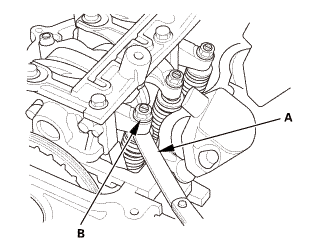

Move the auto-tensioner (A) counterclockwise to relieve tension

from the drive belt (B).

|

|

2.

|

Remove the drive belt.

|

|

|

|

|

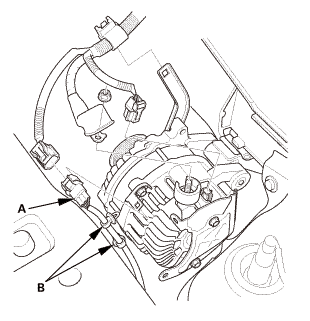

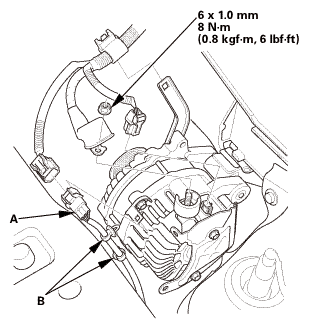

1.

|

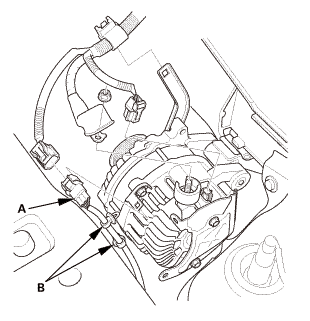

Disconnect the connector and the cable.

|

|

2.

|

Remove the harness connector (A) and the harness clamps (B).

|

|

|

|

|

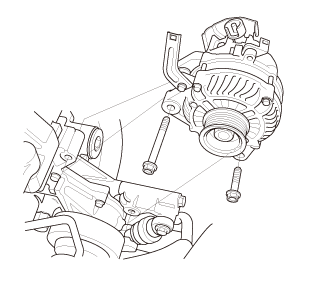

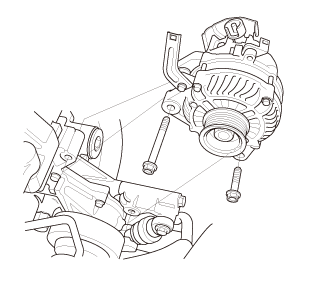

3.

|

Remove the alternator.

|

|

|

|

|

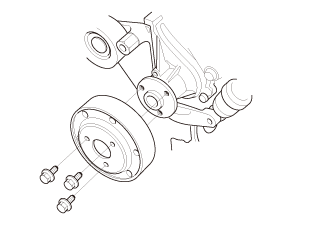

1.

|

Remove the water pump pulley.

|

|

| 10. |

Auto Tensioner Assembly |

|

|

|

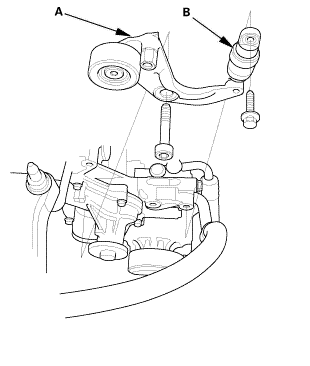

1.

|

Remove the drive belt auto-tensioner (A).

|

|

2.

|

Check for oil leaks from the drive belt auto-tensioner damper

(B) and check for damage to the damper rubber.

|

|

|

|

|

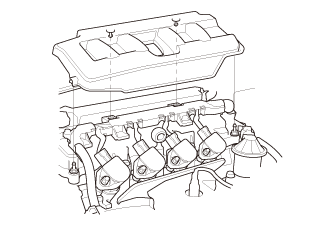

1.

|

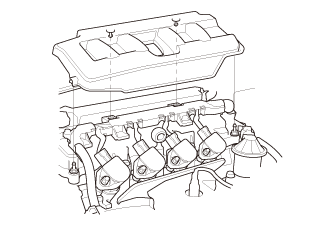

Remove the engine cover.

|

|

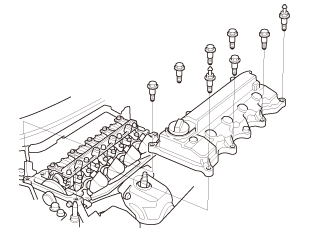

| 12. |

Cylinder Head Cover Peripheral Assembly |

|

|

|

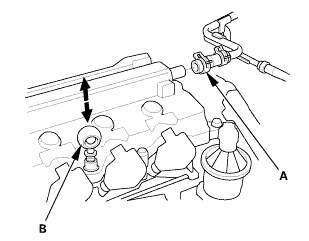

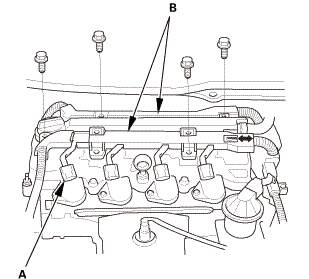

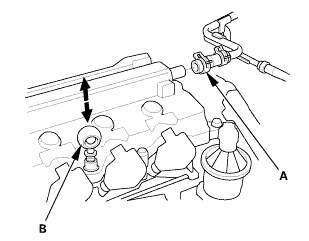

1.

|

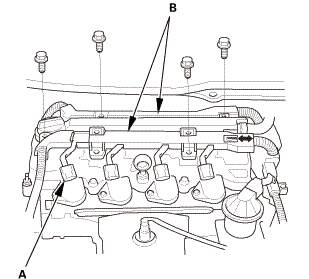

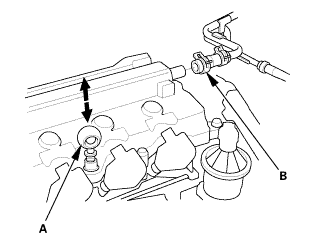

Disconnect the connecters (A).

|

|

2.

|

Remove the harness holders (B).

|

|

| 13. |

Cylinder Head Cover and/or Packing |

|

|

|

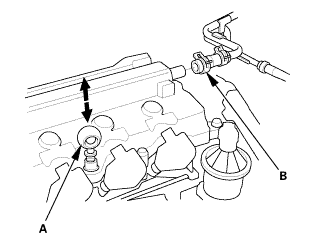

1.

|

Remove the dipstick (A).

|

|

2.

|

Disconnect the breather hose (B).

|

|

|

|

|

3.

|

Remove the cylinder head cover.

|

|

| 14. |

Check The No.1 Piston at Top Dead Center (With Cam Chain Case/Oil Pump) |

|

|

|

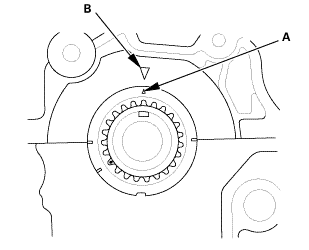

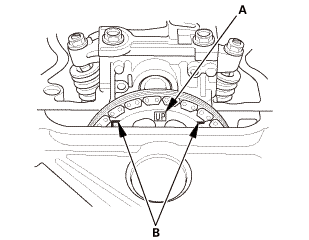

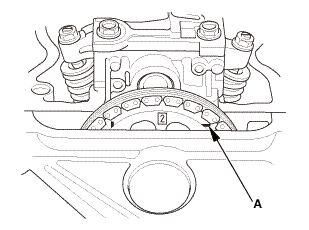

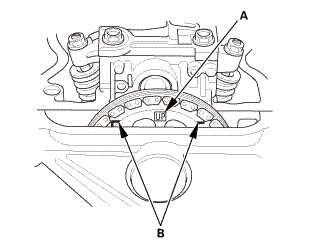

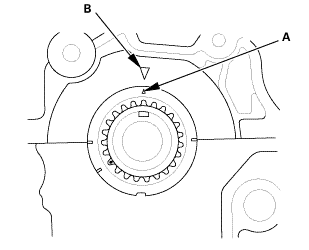

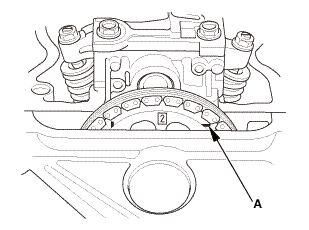

1.

|

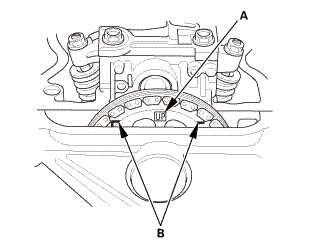

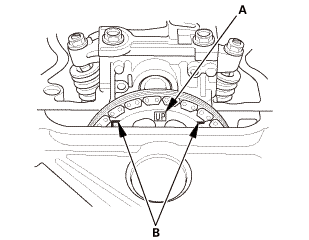

Set the No. 1 piston at top dead center (TDC). The ‘‘UP’’

mark (A) on the camshaft sprocket should be at the top, and the

TDC grooves (B) on the camshaft sprocket should line up with the

top edge of the head.

|

|

|

[av [av

|

|

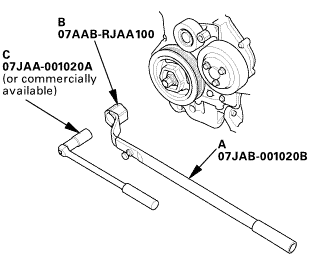

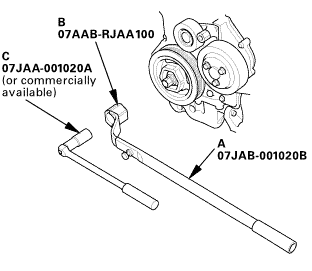

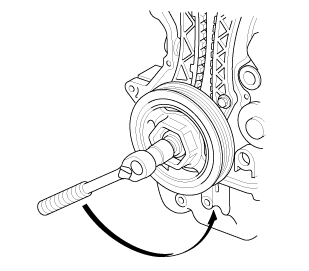

1.

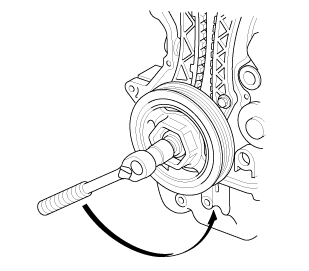

|

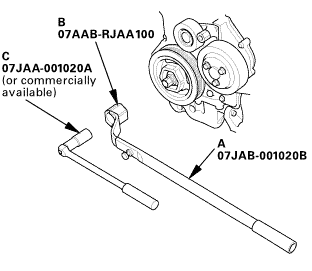

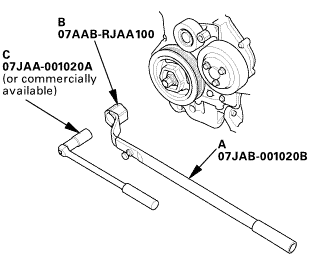

Hold the pulley with the holder handle (A) and the crankshaft

pulley holder (B).

|

|

2.

|

Remove the bolt with a socket, 19 mm (C) and a breaker bar.

|

|

3.

|

Remove the crankshaft pulley.

|

|

| 16. |

Engine Jack Support (State Of A Low Vehicle) |

|

|

1.

|

Lift and support the engine with a jack and a wood block under

the oil pan.

|

|

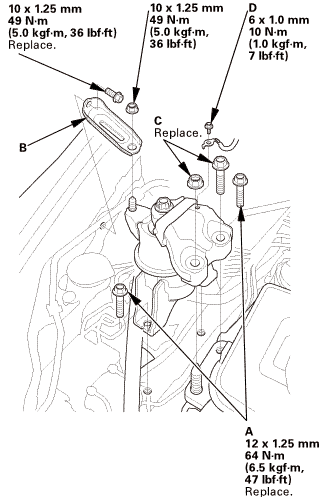

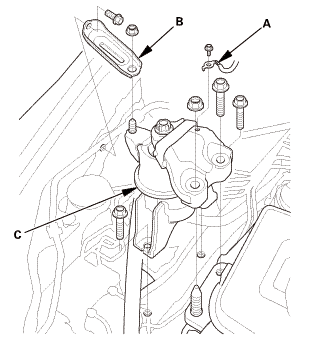

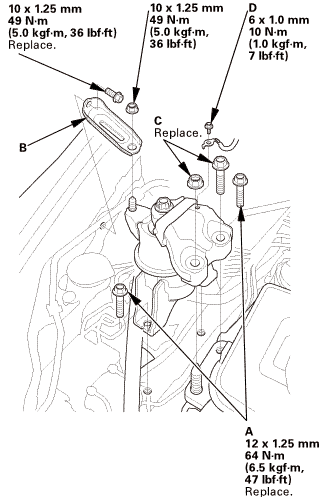

| 17. |

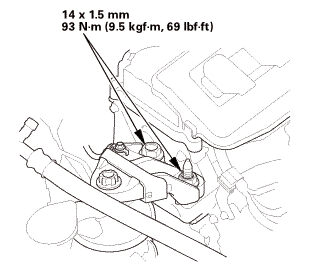

Mounting Bracket, Engine Side |

|

|

|

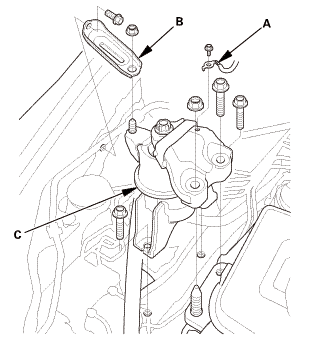

1.

|

Remove the ground cable (A), the side engine mount bracket (B),

and the side engine mount (C).

|

|

| 18. |

Engine Oil Pump Assembly |

|

|

|

1.

|

Disconnect the PCV hose.

|

|

| 19. |

Cam Chain Auto-Tensioner |

|

|

|

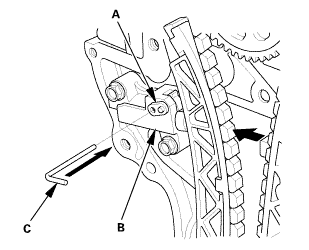

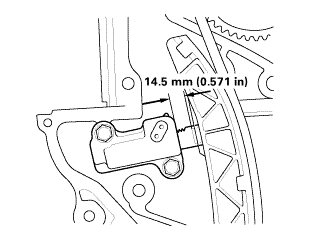

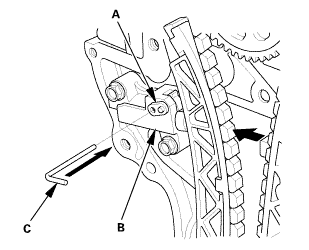

1.

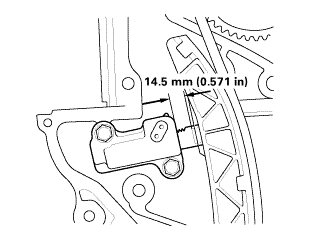

|

Measure the tensioner rod length between the tensioner body and

bottom of the flat surface section on the tensioner rod. If the

length is more than the service limit, replace the cam chain.

|

|

|

Tensioner Rod Length

|

|

Service Limit:

|

14.5 mm (0.571 in)

|

|

|

|

|

|

|

|

2.

|

Loosely install the crankshaft pulley.

|

|

3.

|

Turn the crankshaft counterclockwise to compress the auto-tensioner.

|

|

|

|

|

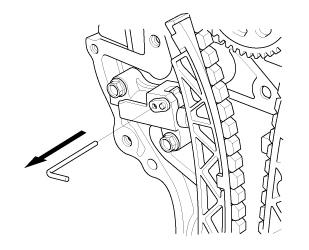

4.

|

Rotate the crankshaft counterclockwise to align the holes on

the lock (A) and the auto-tensioner (B).

|

|

5.

|

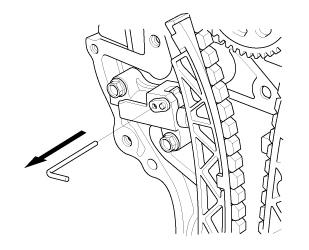

Insert a 1.0 mm (1/32 in) diameter pin (C) into the holes.

|

|

6.

|

Turn the crankshaft clockwise to secure the pin.

|

|

NOTE: If the holes in the lock and the auto-tensioner do not

align, continue to rotating the crankshaft counterclockwise until

the holes align, then install the pin.

|

|

|

|

|

7.

|

Remove the cam chain auto-tensioner.

|

|

8.

|

Remove the crankshaft pulley.

|

|

|

|

|

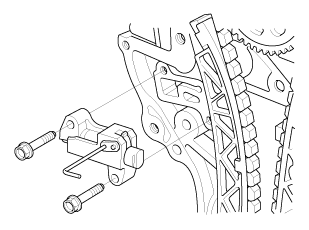

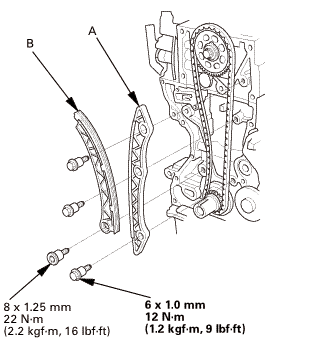

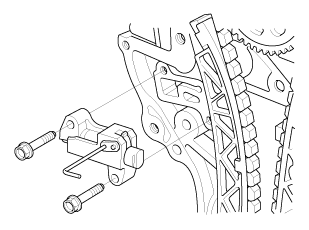

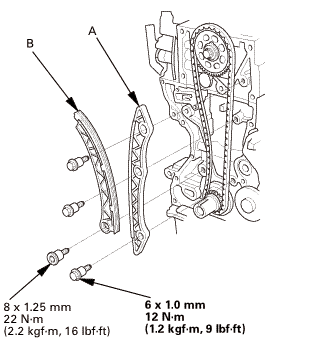

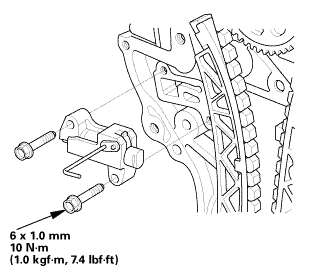

1.

|

Remove the cam chain guide (A) and the cam chain tensioner arm

(B).

|

|

|

|

|

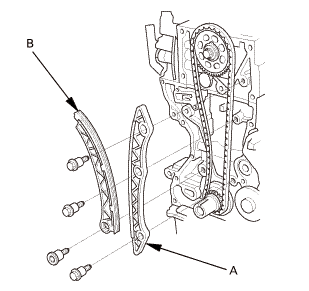

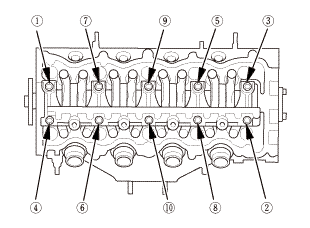

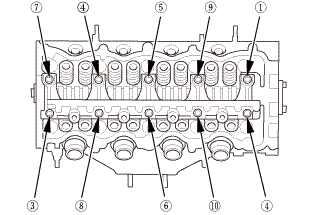

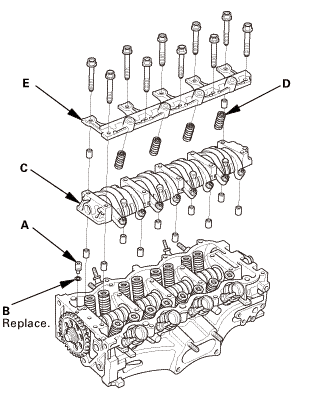

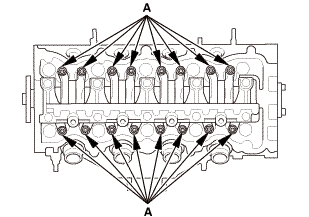

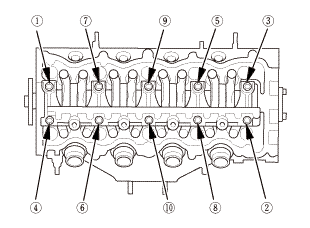

1.

|

Loosen the locknuts and the adjusting screws (A).

|

|

|

|

|

2.

|

Remove the lost motion holder bolts. To prevent damaging the

lost motion holder and the rocker shaft.

|

|

3.

|

loosen the bolts, in sequence, two turns at a time.

|

|

|

|

|

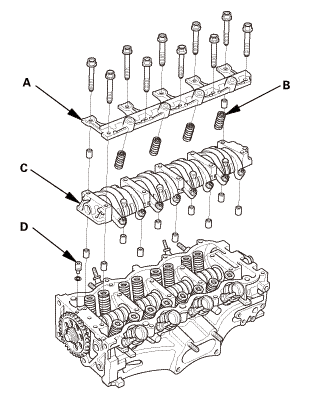

4.

|

Remove the lost motion holder (A) and the lost motion assemblies

(B).

|

|

5.

|

Remove the rocker arm assembly (C).

|

|

6.

|

Remove the oil control orifice (D).

|

|

| 22. |

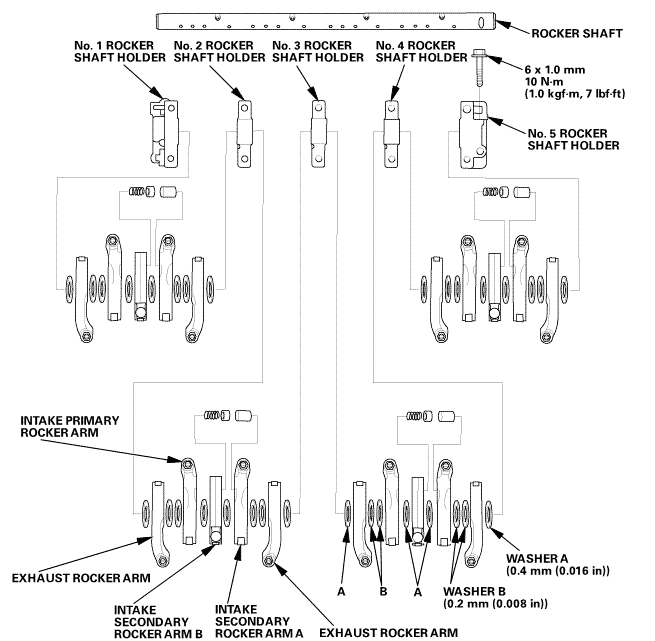

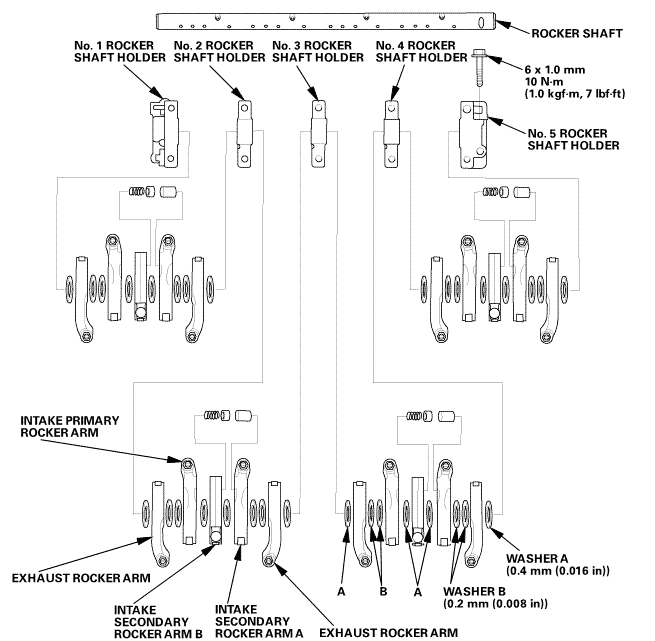

Rocker Arm Assembly - Disassembly |

|

|

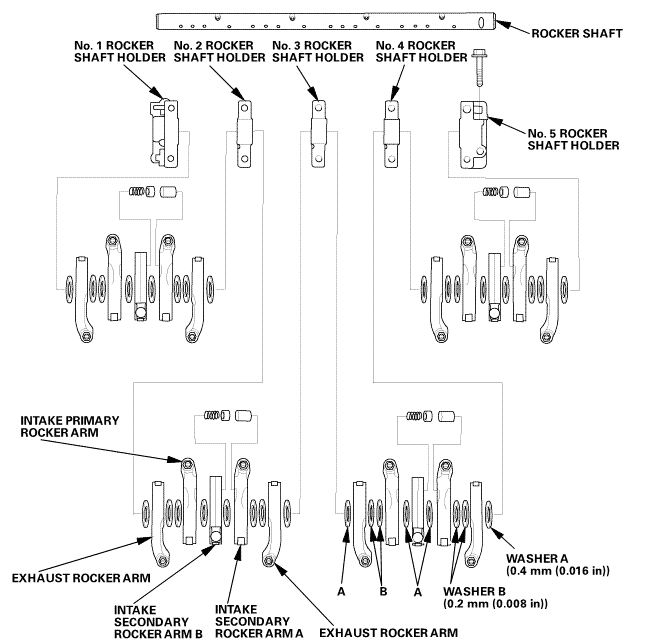

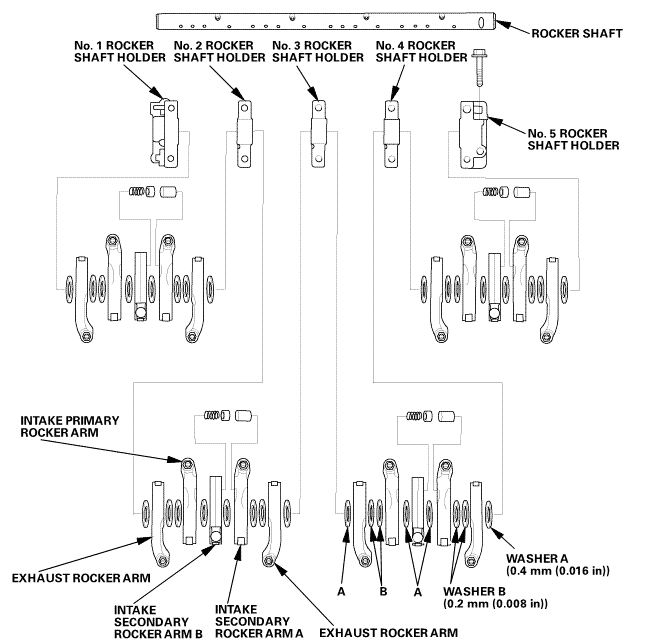

Identify parts as they are removed so they can be reinstalled

in their original locations.

|

|

|

|

Inspect the rocker shaft and the rocker arms.

|

|

|

|

When removing, or installing the rocker arm assembly, do not

remove the camshaft holder bolts. The bolts will keep the holders

and the rocker arms on the shaft.

|

|

|

|

Remove the rocker shaft bolt before removing the rocker shaft

from the No. 5 rocker shaft holder.

|

|

|

|

Bundle the intake and the exhaust rocker arms with rubber bands

to keep them together as a set, and remove the bands after the intake

and exhaust rocker arms have been installed.

|

|

shafyna.na.holderj.inmm

shafyna.na.holderj.inmm

|

|

|

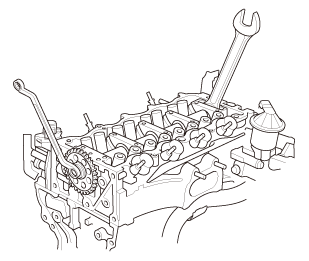

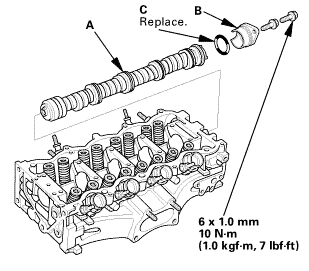

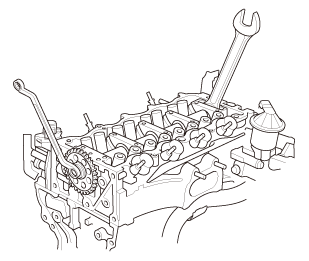

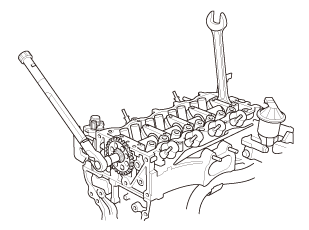

1.

|

Hold the camshaft with a 27 mm open-end wrench.

|

|

2.

|

loosen the camshaft sprocket mounting bolt.

|

|

3.

|

Remove the camshaft sprocket.

|

|

| 1. |

Camshaft End Play - Inspection |

|

|

|

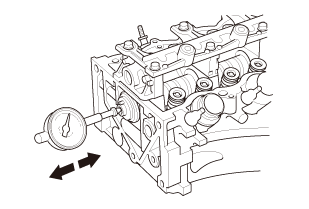

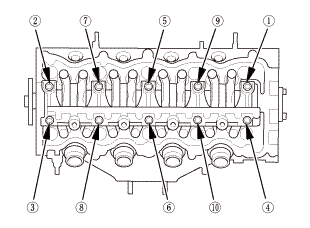

1.

|

Put the rocker shaft holders and the lost motion holder on the

cylinder head, then tighten the bolts, in sequence, to the specified

torque.

|

|

|

Specified Torque:

|

|

6 x 1.0 mm 15 N·m (1.5 kgf·m, 11 lbf·ft)

|

|

|

|

|

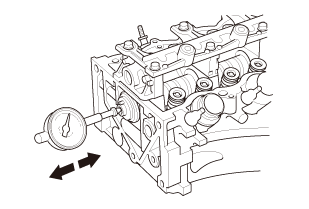

2.

|

Seat the camshaft by pushing it away from the camshaft pulley

end of the cylinder head.

|

|

|

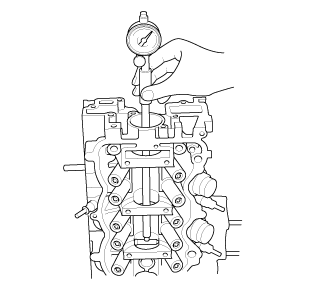

3.

|

Zero the dial indicator against the end of the camshaft, then push the

camshaft back and forth, and read the end play. If the end play is beyond

the service limit, replace the thrust cover and recheck. If it is still

beyond the service limit, replace the cylinder head. If it is still beyond

the service limit, replace the camshaft.

|

|

NOTE: Do not rotate the camshaft during inspection.

|

|

|

Camshaft End Play

|

|

Standard (New):

|

0.05-0.25 mm (0.0020-0.0098 in)

|

|

Service Limit:

|

0.4 mm (0.016 in)

|

|

|

|

|

|

|

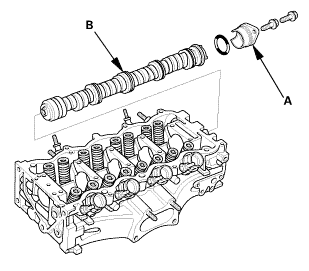

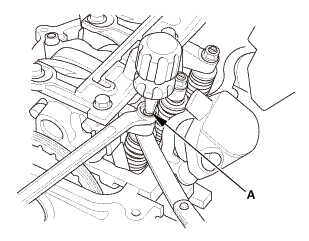

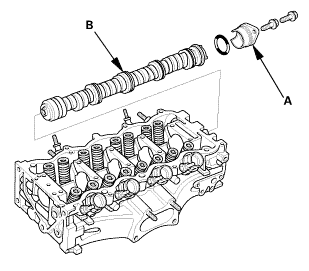

1.

|

Remove the camshaft thrust cover (A).

|

|

2.

|

Pull out the camshaft (B).

|

|

|

|

|

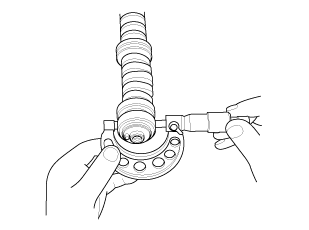

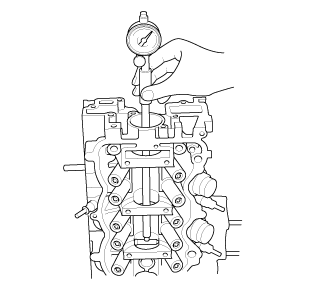

1.

|

Wipe the camshaft clean, then inspect the lift ramps. Replace

the camshaft if any lobes are pitted, scored, or excessively worn.

|

|

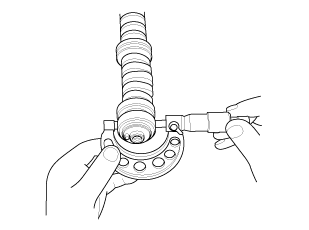

2.

|

Measure the diameter of each camshaft journal.

|

|

|

|

|

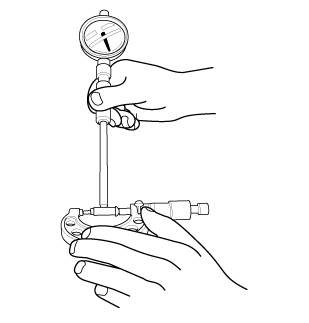

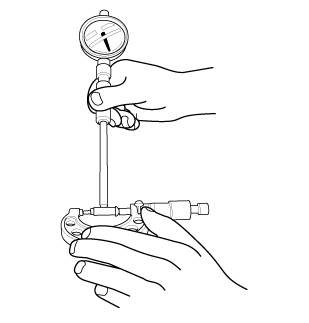

3.

|

Zero the gauge to the journal diameter.

|

|

|

4.

|

Clean the camshaft bearing surfaces in the cylinder head. Measure the

inside diameter of each camshaft bearing surface, and check for an out-of-round

condition:

|

|

|

If the camshaft-to-holder clearance is within limits,

go to step 6.

|

|

|

|

If the camshaft-to-holder clearance is beyond the service

limit, and the camshaft has been replaced, replace the cylinder

head.

|

|

|

|

If the camshaft-to-holder clearance is beyond the service

limit, and the camshaft has not been replaced, go to step

5.

|

|

|

|

|

Camshaft-to-Holder Oil Clearance

|

|

Standard (New):

|

0.045-0.084 mm (0.00177-0.00331 in)

|

|

Service Limit:

|

0.15 mm (0.0059 in)

|

|

|

|

|

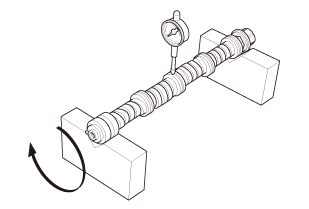

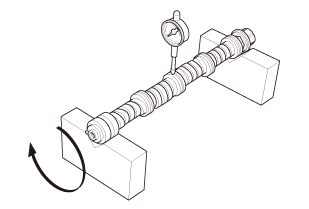

5.

|

Check the total runout with the camshaft supported on V-blocks.

|

|

|

If the total runout of the camshaft is within the service

limit, replace the cylinder head.

|

|

|

|

If the total runout is beyond the service limit, replace

the camshaft, and recheck the oil clearance. If the oil

clearance is still beyond the service limit, replace the

cylinder head.

|

|

|

|

|

Camshaft Total Runout

|

|

Standard (New):

|

0.03 mm (0.0012 in) max.

|

|

|

|

|

6.

|

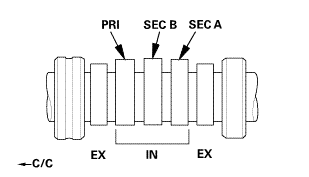

Measure the cam lobe height.

|

|

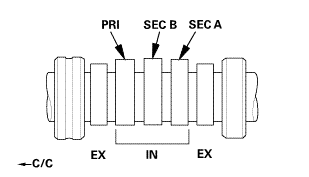

Cam Lobe Height Standard (New):

|

|

USA and Canada models

| |

INTAKE

|

EXHAUST

|

|

PRI

|

35.866 mm (1.41204 in)

|

35.870 mm (1.41220 in)

|

|

SEC A

|

30.818 mm (1.21330 in)

|

|

SEC B

|

35.689 mm (1.40508 in)

|

|

|

|

|

Mexico models

| |

INTAKE

|

EXHAUST

|

|

PRI

|

35.979 mm (1.41649 in)

|

35.870 mm (1.41220 in)

|

|

SEC A

|

36.027 mm (1.41838 in)

|

|

SEC B

|

35.471 mm (1.39649 in)

|

|

|

|

|

|

PRI: Primary

|

SEC: Secondary

|

IN: Intake

|

|

EX: Exhaust

|

C/C: Cam Chain

|

|

|

|

|

secasx

secasx

|

7.

|

Remove the rocker shaft holders and the lost motion holder

|

|

tommnomm tommnomm

|

|

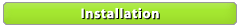

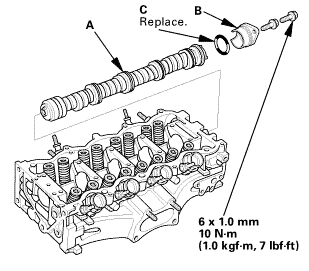

1.

|

Install the camshaft (A).

|

|

2.

|

Install the camshaft thrust cover (B) with a new O-ring (C).

|

|

|

|

|

1.

|

Install the camshaft sprocket.

|

|

2.

|

Apply new engine oil to the threads of the camshaft sprocket

mounting bolt.

|

|

3.

|

Install the camshaft sprocket mounting bolt.

|

|

4.

|

Hold the camshaft with a 27 mm open-end wrench.

|

|

5.

|

Tighten the camshaft sprocket mounting bolt.

|

|

|

Specified Torque:

|

|

10 x 1.25 mm 57 N·m (5.8 kgf·m, 42 lbf·ft)

|

|

|

|

|

| 3. |

Rocker Arm Assembly - Reassembly |

|

|

If reused, the rocker arms must be installed in their original

locations.

|

|

|

|

When removing, or installing the rocker arm assembly, do not

remove the camshaft holder bolts. The bolts will keep the holders

and the rocker arms on the shaft.

|

|

|

|

Bundle the intake and the exhaust rocker arms with rubber bands

to keep them together as a set, and remove the bands after the intake

and exhaust rocker arms have been installed.

|

|

|

|

Prior to reassembling, clean all the parts in solvent, dry them,

and apply new engine oil to all contact points, the bearing surface,

and the lost motion assembly.

|

|

|

|

When replacing the rocker arm assembly, remove the fastening

hardware from the new rocker arm assembly.

|

|

shafy[hiinyakeprimarvnockinarminmm

shafy[hiinyakeprimarvnockinarminmm

|

|

|

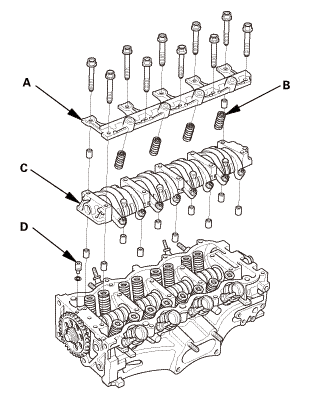

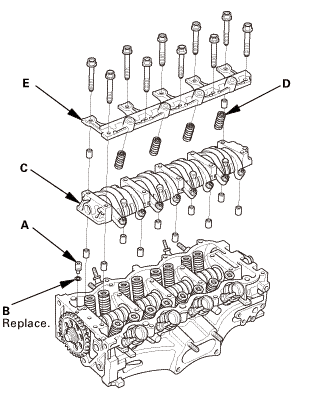

1.

|

If the rocker arm assembly is disassembled, reassemble the rocker

arm assembly.

|

|

2.

|

Install the oil control orifice (A) with a new O-ring (B).

|

|

3.

|

Install the rocker arm assembly (C).

|

|

4.

|

Install the lost motion assembles (D) and the lost motion holder

(E).

|

|

NOTE: Apply new engine oil to the lost motion assembly.

|

|

|

|

|

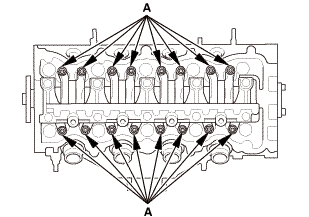

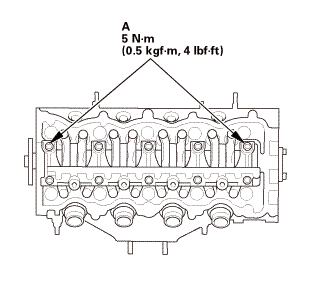

5.

|

Tighten the two lost motion holder bolts (A).

|

|

|

|

|

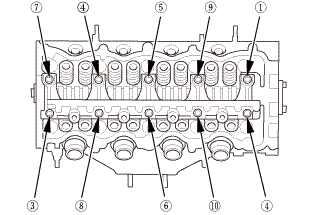

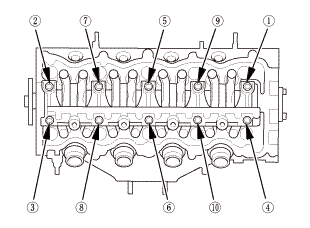

6.

|

Tighten each bolts two turns at a time in sequence.

|

|

|

Specified Torque:

|

|

6 x 1.0 mm 15 N·m (1.5 kgf·m, 11 lbf·ft)

|

|

|

|

|

| 5. |

Set The Crankshaft To Top Dead Center |

|

|

|

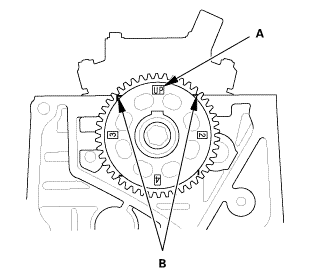

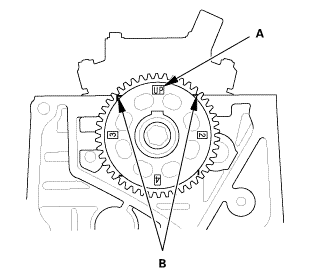

1.

|

Set the crankshaft to top dead center (TDC). Align the TDC mark

(A) on the crankshaft sprocket with the pointer (B) on the engine

block.

|

|

| 6. |

Set The No.1 Piston at Top Dead Center (Without Cam Chain Case/Oil Pump) |

|

|

|

1.

|

Set the camshaft to TDC. The ‘‘UP’’ mark (A) on the camshaft

sprocket should be at the top, and the TDC grooves (B) on the camshaft

sprocket should line up with the top edge of the head.

|

|

|

|

|

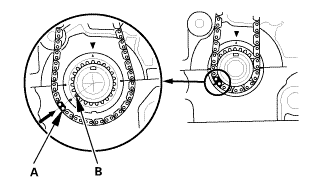

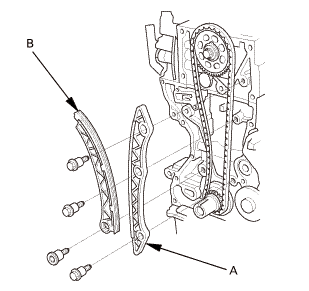

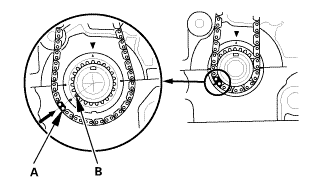

1.

|

Install the cam chain on the crankshaft sprocket with the colored

piece (A) aligned with the mark (B) on the crankshaft sprocket.

|

|

|

|

|

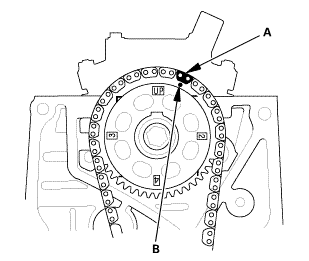

2.

|

Install the cam chain on the camshaft sprocket with the colored

link plate (A) aligned with the mark (B) on the camshaft sprocket.

|

|

|

...,is(1.2 ...,is(1.2

|

|

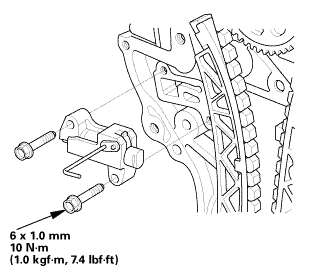

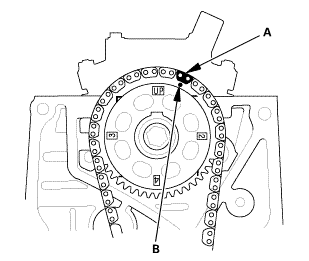

3.

|

Install the cam chain guide (A) and the cam chain tensioner arm

(B).

|

|

| 8. |

Cam Chain Auto-Tensioner |

|

|

|

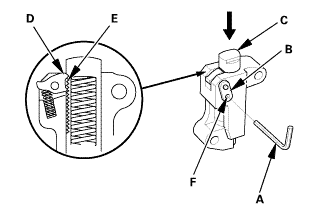

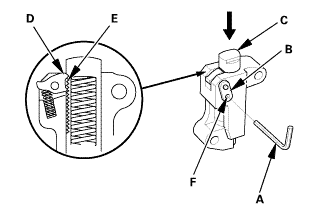

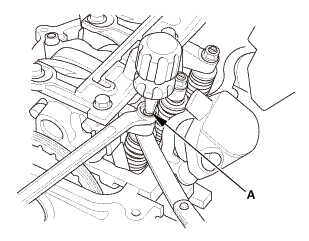

1.

|

Compress the cam chain auto-tensioner when replacing the cam

chain. Remove the pin (A) from the auto-tensioner that was installed

during removal. Turn the plate (B) counterclockwise, to release

the lock, then press the rod (C), and set the first cam (D) to the

first edge of the rack (E). Insert the 1.0 mm (1/32 in) diameter

pin back into the holes (F).

|

|

NOTE: If the chain tensioner is not set up as described, the

tensioner will be damaged.

|

|

|

nokvf-in. nokvf-in.

|

|

2.

|

Install the cam chain auto-tensioner.

|

|

|

|

|

3.

|

Remove the pin from the cam chain auto-tensioner.

|

|

| 9. |

Engine Oil Pump Assembly |

|

|

|

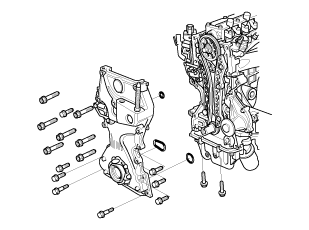

1.

|

Check the oil pump oil seal for damage. If the oil seal is damaged,

replace the oil seal.

|

|

2.

|

Remove all of the old liquid gasket from the oil pump mating

surfaces, the bolts, and the bolt holes.

|

|

3.

|

Clean and dry the oil pump mating surfaces.

|

|

4.

|

Apply liquid gasket (P/N 08718-0004 or 08718-0009) to the engine

block mating surface of the oil pump, and to the inside edge of

the threaded bolt holes. Install the component within 5 minutes

of applying the liquid gasket.

|

|

NOTE:

|

|

|

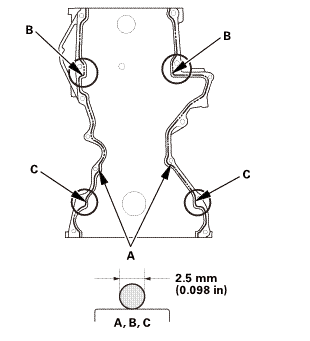

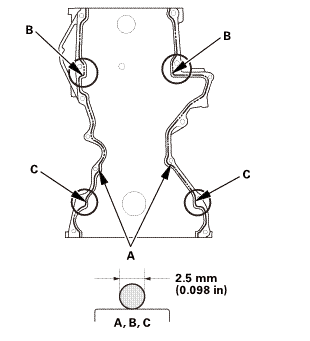

Apply a 2.5 mm (0.098 in) diameter bead of liquid

gasket along the broken line (A), (B), and (C).

|

|

|

|

If too much time has passed after applying the

liquid gasket, remove the old liquid gasket and

residue, then reapply new liquid gasket.

|

|

|

|

|

|

|

5.

|

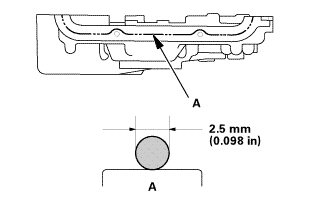

Apply liquid gasket (P/N 08718-0004 or 08718-0009) to the oil

pan mating surface of the oil pump, and to the inside edge of the

threaded bolt holes. Install the component within 5 minutes of applying

the liquid gasket.

|

|

|

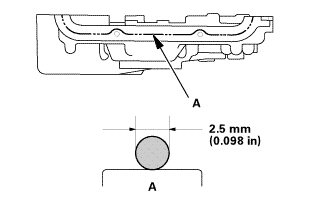

Apply a 2.5 mm (0.098 in) diameter bead of liquid

gasket along the broken line (A).

|

|

|

|

If too much time has passed after applying the

liquid gasket, remove the old liquid gasket and

residue, then reapply new liquid gasket.

|

|

|

|

|

25mm(7(32k1n1omm12 25mm(7(32k1n1omm12

|

|

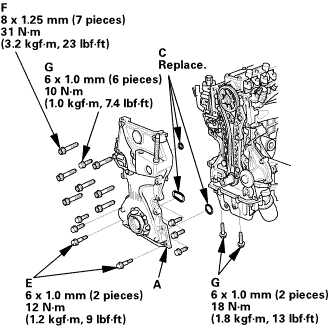

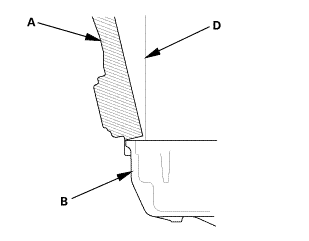

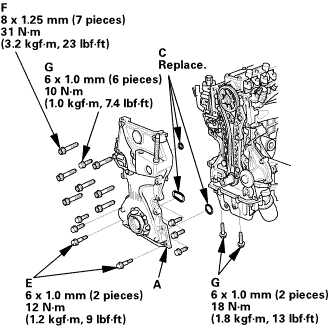

6.

|

Set the edge of the oil pump (A) on the edge of the oil pan (B)

with new O-rings (C).

|

|

7.

|

Install the oil pump on the engine block (D).

|

|

8.

|

Loosely install the dowel bolts (E), then tighten the 8mmbolts

(F), the 6 mm bolts (G) and the dowel bolts.

|

|

9.

|

Wipe off the excess liquid gasket on the oil pan and oil pump

mating surface.

|

|

NOTE:

|

|

|

When installing the oil pump, do not slide the

bottom surface onto the oil pan mounting surface.

|

|

|

|

Wait at least 30 minutes before filling the engine

with oil.

|

|

|

|

Do not run the engine within 3 hours after installing

the oil pump.

|

|

|

|

| 10. |

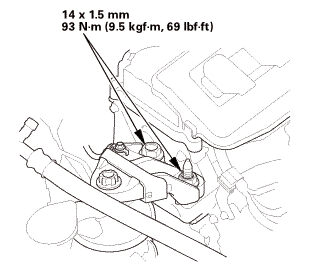

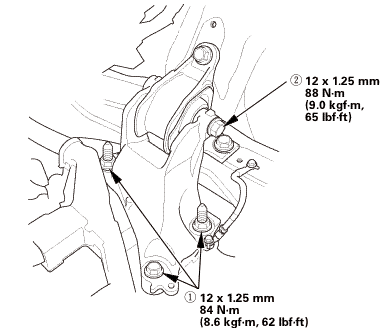

Mounting Bracket, Engine Side |

|

125mmnminm.:125mm 125mmnminm.:125mm

|

|

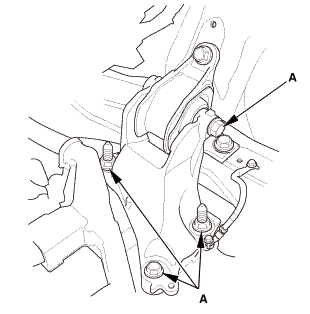

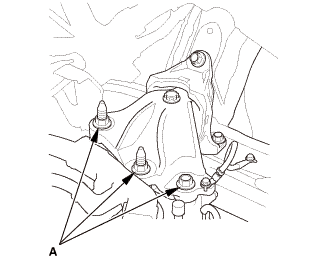

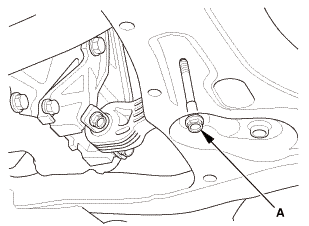

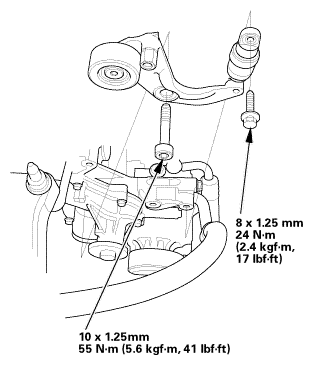

1.

|

Install the new side engine mount mounting bolts (A) and the

side engine mount bracket (B) using a nut and a new bolt, then loosely

install the new side engine mount bracket mounting bolts and nut

(C).

|

|

2.

|

Install the ground cable (D).

|

|

| 11. |

Engine Jack Support (State Of A Low Vehicle) |

|

|

1.

|

Remove the jack and the wood block.

|

|

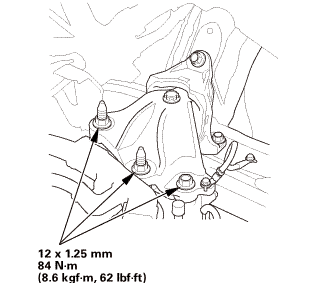

| 12. |

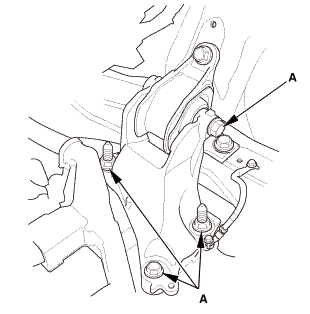

Transmission Mount Bracket Mounting Bolt - Loosen |

|

M/T

A/T

|

|

1.

|

Loosen the transmission mount bracket mounting bolt and nuts

(A).

|

|

| 13. |

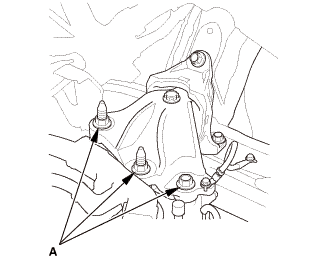

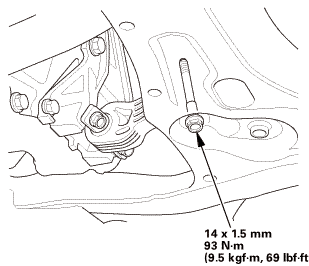

Lower Torque Rod - Loosen |

|

|

|

1.

|

Loosen the lower torque rod mounting bolt (A).

|

|

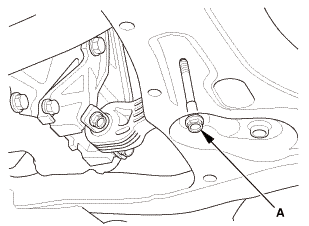

| 14. |

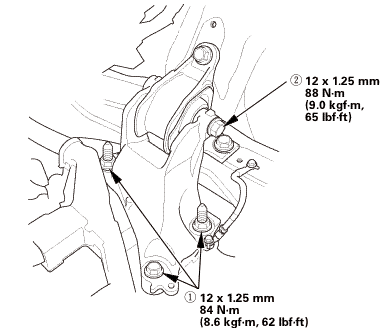

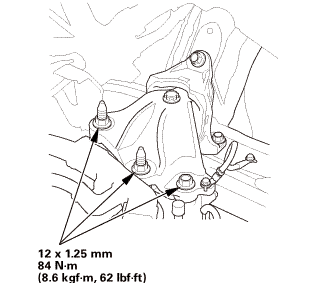

Side Engine Mount - Tighten |

|

nxl.mm nxl.mm

|

|

1.

|

Tighten the side engine mount bracket mounting bolt and nut.

|

|

| 15. |

Transmission Mount Bracket Mounting Bolt - Tighten |

|

1.

|

Tighten the transmission mount bracket mounting bolt and nuts.

|

M/T

i2mm

i2mm

A/T

nz

nz

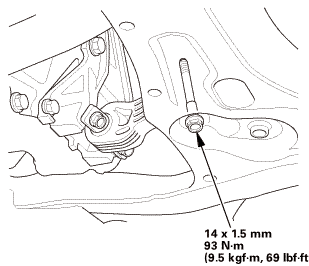

| 16. |

Lower Torque Rod Mounting Bolt - Tighten |

|

|

|

1.

|

Tighten the lower torque rod mounting bolt.

|

|

|

|

|

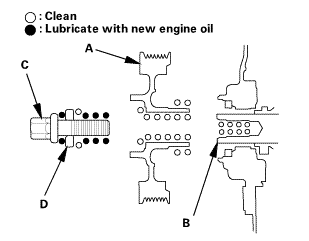

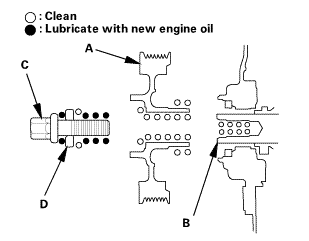

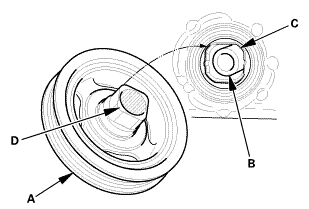

1.

|

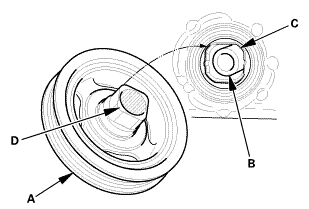

Clean the crankshaft pulley (A), the crankshaft (B), the bolt

(C), and the washer (D).

|

|

2.

|

Lubricate with new engine oil as shown.

|

|

|

|

|

3.

|

Install the crankshaft pulley (A) onto the crankshaft (B) by

aligning the flat sides (C) of the pulley with the flat sides (D)

of the inner oil pump gear.

|

|

|

o7jaanmo2oa o7jaanmo2oa

|

|

When a new crankshaft or a new pulley bolt is installed

|

|

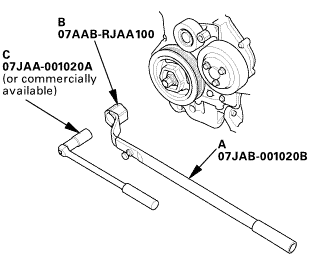

4.

|

Hold the pulley with the holder handle (A) and crankshaft pulley

holder (B), torque the bolt to 180 N·m (18.4 kgf·m, 133 lbf·ft)

with a torque wrench and a socket (C), then remove the bolt.

|

|

5.

|

Torque the bolt to 50 N·m (5.1 kgf·m, 37 lbf·ft) with a torque

wrench and a socket.

|

|

NOTE: Tighten the crankshaft pulley bolt. Do not use an impact

wrench.

|

|

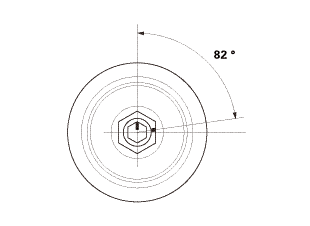

6.

|

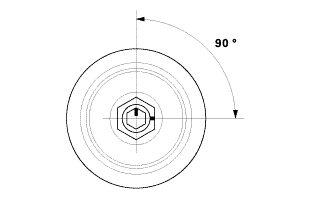

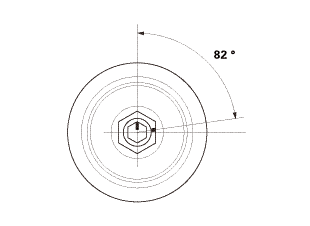

Tighten the bolt an additional 82 °.

|

|

|

o7jaanmo2oa o7jaanmo2oa

|

|

When the crankshaft or the pulley bolt is reused

|

|

7.

|

Hold the pulley with the holder handle (A) and crankshaft pulley

holder (B), then torque the bolt to 70 N·m (7.1 kgf·m, 52 lbf·ft)

with a torque wrench and a socket (C).

|

|

NOTE: Tighten the crankshaft pulley bolt. Do not use an impact

wrench.

|

|

8.

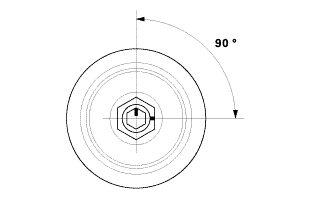

|

Tighten the bolt an additional 90 °.

|

|

| 18. |

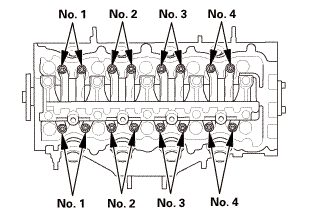

Valve Clearance Adjustment |

|

|

|

1.

|

Set the No. 1 piston at top dead center (TDC). The ‘‘UP’’

mark (A) on the camshaft sprocket should be at the top, and the

TDC grooves (B) on the camshaft sprocket should line up with the

top edge of the head.

|

|

|

2.

|

Select the correct feeler gauge for the valve clearance you are going

to check.

|

|

|

Valve Clearance

|

|

Intake:

|

0.18-0.22 mm (0.008-0.008 in)

|

|

Exhaust:

|

0.23-0.27 mm (0.010-0.010 in)

|

|

|

|

no!

no!

|

|

|

3.

|

Insert the feeler gauge (A) between the adjusting screw (B) and

the end of the valve stem on the No. 1 cylinder, and slide it back

and forth; you should feel a slight amount of drag.

|

|

|

|

|

4.

|

If you feel too much or too little drag, loosen the locknut,

and turn the adjusting screw (A) until the drag on the feeler gauge

is correct.

|

|

5.

|

Tighten the locknut to the specified torque, and recheck the

clearance. Repeat the adjustment if necessary.

|

|

|

Specified Torque

|

|

7 x 0.75 mm

|

|

14 N·m (1.4 kgf·m, 10 lbf·ft)

|

|

Apply new engine oil to the nut threads.

|

|

|

|

|

|

|

|

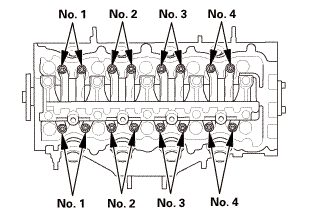

6.

|

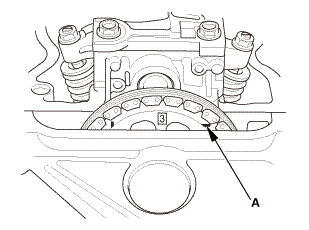

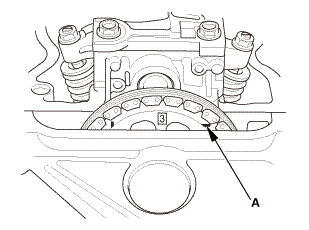

Rotate the crankshaft clockwise. Align the No. 3 piston TDC groove

(A) on the camshaft sprocket with the top edge of the head.

|

|

7.

|

Check and, if necessary, adjust the valve clearance on the No.

3 cylinder.

|

|

|

|

|

8.

|

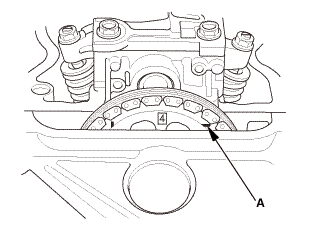

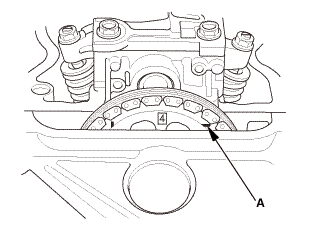

Rotate the crankshaft clockwise. Align the No. 4 piston TDC groove

(A) on the camshaft sprocket with the top edge of the head.

|

|

9.

|

Check and, if necessary, adjust the valve clearance on the No.

4 cylinder.

|

|

|

|

|

10.

|

Rotate the crankshaft clockwise. Align the No. 2 piston TDC groove

(A) on the camshaft sprocket with the top edge of the head.

|

|

11.

|

Check and, if necessary, adjust the valve clearance on the No.

2 cylinder.

|

|

| 19. |

Cylinder Head Cover and/or Packing |

|

|

|

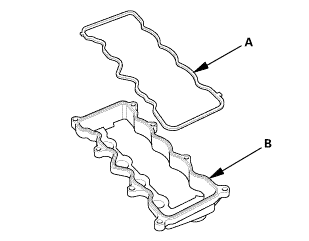

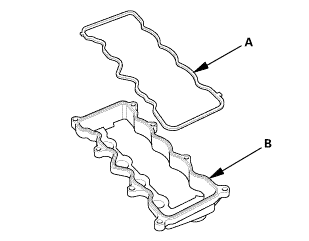

1.

|

Thoroughly clean the head cover gasket and the groove.

|

|

NOTE: Check and, if necessary, replace the head cover gasket.

|

|

2.

|

Install the head cover gasket (A) in the groove of the cylinder

head cover (B).

|

|

3.

|

Make sure the head cover gasket is seated securely.

|

|

4.

|

Clean the head cover contacting surfaces with a shop towel.

|

|

|

|

|

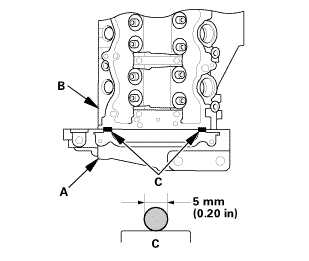

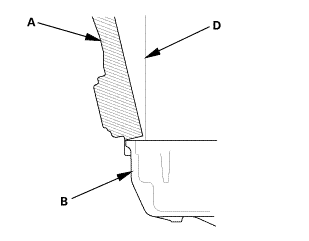

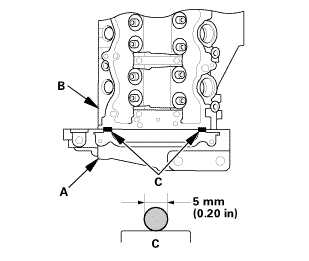

5.

|

Remove the old liquid gasket from the top edge matting surfaces

of the oil pump (A) and cylinder head (B).

|

|

6.

|

Apply liquid gasket (P/N 08718-0004 or 08718-0009) to the chain

case contact areas. Install the component within 5 minutes of applying

the liquid gasket.

|

|

NOTE:

|

|

|

Apply a 5 mm (0.20 in) diameter bead of liquid

gasket to the mating surfaces (C).

|

|

|

|

If too much time has passed after applying the

liquid gasket, remove the old liquid gasket and

residue, then reapply new liquid gasket.

|

|

|

|

|

|

|

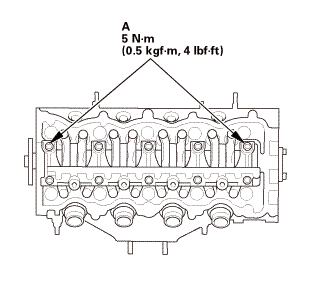

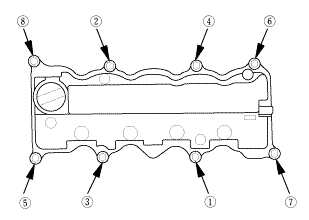

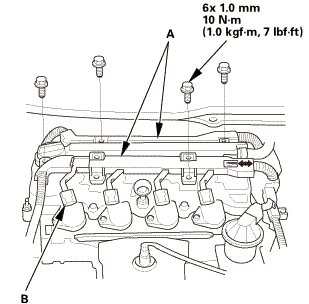

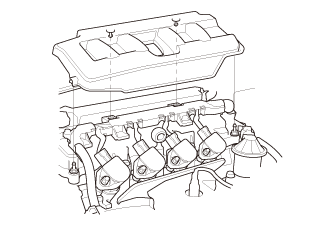

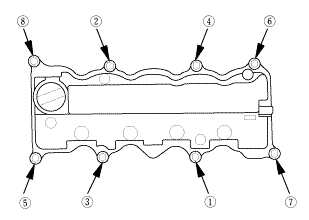

7.

|

Install the cylinder head cover.

|

|

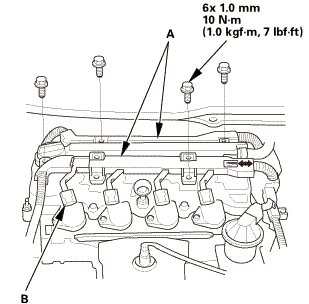

8.

|

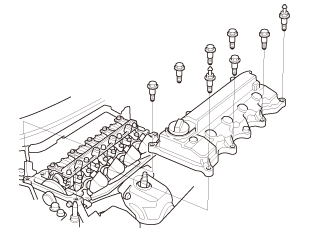

Tighten the bolts in two steps. In the final step, torque all

bolts in sequence to 10 N·m (1.0 kgf·m, 7 lbf·ft).

|

|

NOTE:

|

|

|

Wait at least 30 minutes before filling the engine

with oil.

|

|

|

|

Do not run the engine for at least 3 hours after

installing the head cover.

|

|

|

|

|

|

|

9.

|

Connect the breather hose (A).

|

|

10.

|

Install the dipstick (B).

|

|

| 20. |

Cylinder Head Cover Peripheral Assembly |

|

mmidnmm, mmidnmm,

|

|

1.

|

Install the harness holders (A).

|

|

2.

|

Connect the connecters (B).

|

|

|

|

|

1.

|

Install the engine cover.

|

|

| 22. |

Auto Tensioner Assembly |

|

inl.25mmssn-m inl.25mmssn-m

|

|

1.

|

Install the drive belt auto-tensioner.

|

|

|

|

|

1.

|

Install the water pump pulley.

|

|

|

mmn-m(2 mmn-m(2

|

|

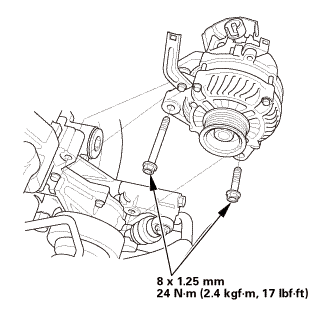

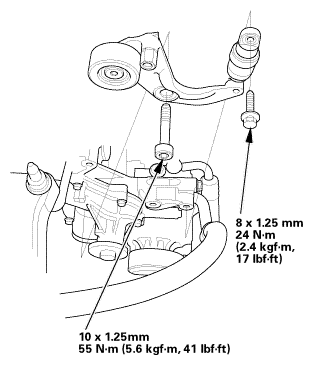

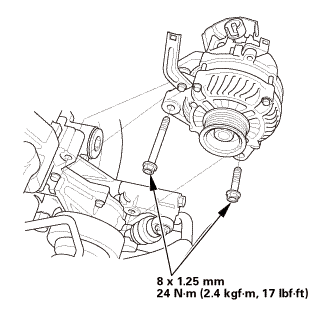

1.

|

Install the alternator.

|

|

|

i.nmm(n.i i.nmm(n.i

|

|

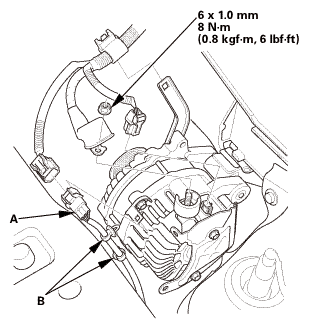

2.

|

Connect the connector and the cable. Make sure the crimped side

of the ring terminal faces away from the alternator when you connect

it.

|

|

3.

|

Install the harness connector (A) and the harness clamps (B).

|

|

|

|

|

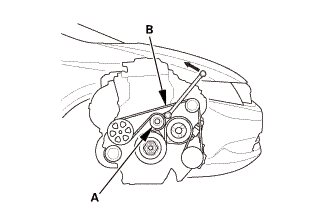

1.

|

Move the auto-tensioner (A) counterclockwise.

|

|

2.

|

Install the drive belt (B).

|

|

| 26. |

Water Pump Pulley Mounting Bolt - Tighten |

|

|

|

1.

|

Tighten the water pump pulley mounting bolts.

|

|

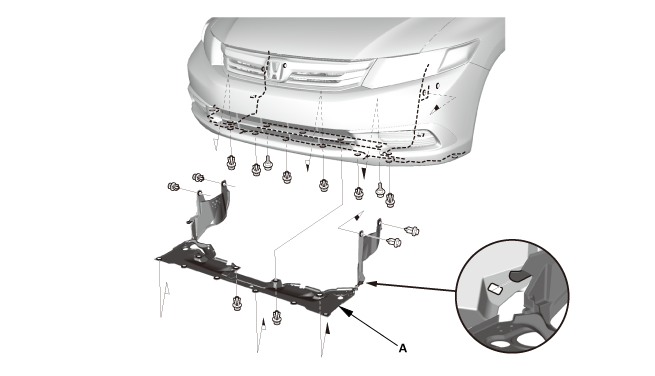

|

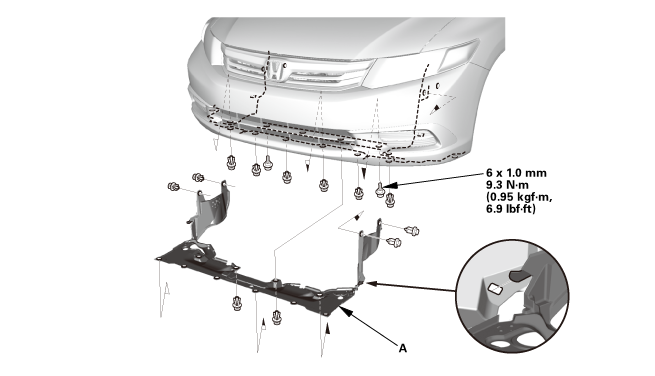

1.

|

Install the splash shield (A).

|

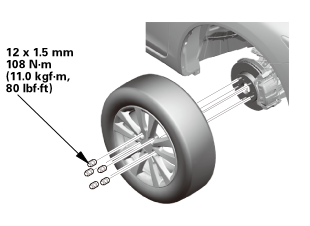

| 28. |

Tire and Wheel-Installation, Front Right |

|

mminmuan mminmuan

|

|

1.

|

Install the right front wheel.

|

|

NOTE: Before installing the wheel, clean the mating surfaces

between the brake disc and the inside of the wheel.

|

|

|

|

|

1.

|

Install the battery (A) and the battery setting plate (B).

|

|

NOTE: Do not deform the battery setting plate by over-tightening

the nuts.

|

|

| 30. |

Battery Terminal - Reconnection |

|

|

|

NOTE: If the battery performs abnormally, test the battery.

|

|

1.

|

Clean the battery terminals.

|

|

2.

|

Connect the positive cable (A) to the battery.

|

|

NOTE: Always connect the positive side first.

|

|

3.

|

Connect the negative cable and the battery sensor (B) to the

battery.

|

|

NOTE: To protect the battery sensor connector (C) from damage,

do not hold it when installing the negative terminal.

|

|

4.

|

Apply multipurpose grease to the terminals to prevent corrosion.

|

|

|

|

|

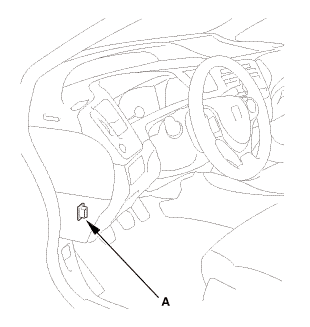

1.

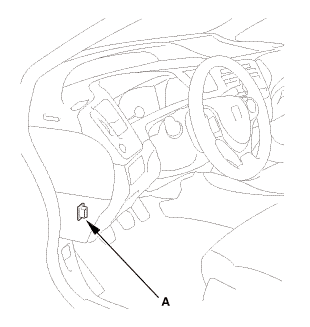

|

Connect the HDS to the data link connector (DLC) (A) located

under the driver's side of the dashboard.

|

|

2.

|

Turn the ignition switch to ON (II).

|

|

3.

|

Make sure the HDS communicates with the vehicle. If it does not

communicate, go to the DLC circuit troubleshooting.

|

|

| 32. |

CKP Pattern Clear/CKP Pattern Learn |

|

|

1.

|

Select CRANK PATTERN in the ADJUSTMENT MENU with the HDS.

|

|

2.

|

Select CRANK PATTERN CLEAR, and clear the CKP pattern.

|

|

3.

|

Select CRANK PATTERN LEARNING with the HDS, and follow the screen

prompts.

|

|

1.

Vehicle Lift

1.

Raise the vehicle on a lift, and make sure it is securely supported.

2. ...

1.

Air Cleaner Assembly

1.

Disconnect the intake air duct (A) and the intake air pipe (B).

...

See also:

Honda Civic Owners Manual. Low Smart Entry Remote Signal Strength

The vehicle transmits radio waves to locate the smart entry remote when

locking/

unlocking the doors and fuel fill door, opening the trunk, or starting the

engine.

In the following cases, locking/unlocking the doors, opening the trunk, or

starting

the engine may be inhibited or operation ...

shafyna.na.holderj.inmm

shafyna.na.holderj.inmm

secasx

secasx

shafy[hiinyakeprimarvnockinarminmm

shafy[hiinyakeprimarvnockinarminmm i2mm

i2mm nz

nz no!

no!

Valve Guide Replacement (R18Z1)

Valve Guide Replacement (R18Z1) Camshaft Removal and Installation (K24Z7)

Camshaft Removal and Installation (K24Z7)

12x1mm

12x1mm

[av

[av

tommnomm

tommnomm

...,is(1.2

...,is(1.2

nokvf-in.

nokvf-in.

25mm(7(32k1n1omm12

25mm(7(32k1n1omm12

125mmnminm.:125mm

125mmnminm.:125mm

nxl.mm

nxl.mm

o7jaanmo2oa

o7jaanmo2oa

mmidnmm,

mmidnmm, inl.25mmssn-m

inl.25mmssn-m mmn-m(2

mmn-m(2 i.nmm(n.i

i.nmm(n.i

mminmuan

mminmuan